jan . 09, 2025 10:58

Back to list

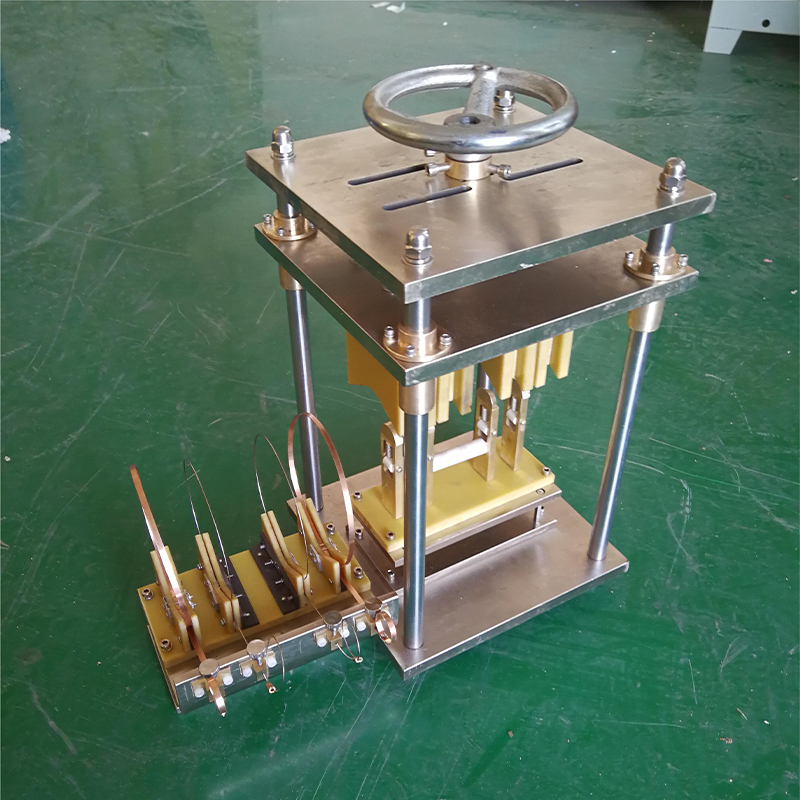

High-Quality Wire & Cable Testing Machines

In the realm of wire and cable manufacturing, the precision and reliability of a wire and cable testing machine are cornerstones for ensuring product integrity and safety. These machines serve as the linchpin for delivering top-tier cables that meet rigorous industrial standards and consumer expectations, underscoring their importance in a technologically driven world.

Authoritativeness in this field is demonstrated through rigorous certifications and adherence to international testing standards. Manufacturers of these machines collaborate with standardization bodies and industry experts to keep their systems updated with the latest requirements. This commitment to adhering to regulatory standards reassures users of the machine’s effectiveness and reliability. For example, machines that conform to UL 1581 standards for electrical performance offer manufacturers a significant advantage, as they assure clients of safety and compliance in different geographic markets. Trustworthiness is the bedrock of any long-term supplier relationship, and it is here that wire and cable testing machines shine. The reliability of these machines builds a manufacturer’s reputation by ensuring consistent product quality. Over time, this consistency fosters trust with both direct consumers and large-scale industrial clients, who require assurance that their investments in high-quality cabling are sound. In conclusion, a wire and cable testing machine is not merely a piece of equipment; it is an integral component of quality assurance processes. By harnessing their advanced capabilities, manufacturers can significantly enhance product quality, ensuring competitiveness in a demanding market. The seamless integration of experience, expertise, authoritativeness, and trustworthiness makes these machines invaluable to any manufacturer serious about producing cables that meet and exceed global standards.

Authoritativeness in this field is demonstrated through rigorous certifications and adherence to international testing standards. Manufacturers of these machines collaborate with standardization bodies and industry experts to keep their systems updated with the latest requirements. This commitment to adhering to regulatory standards reassures users of the machine’s effectiveness and reliability. For example, machines that conform to UL 1581 standards for electrical performance offer manufacturers a significant advantage, as they assure clients of safety and compliance in different geographic markets. Trustworthiness is the bedrock of any long-term supplier relationship, and it is here that wire and cable testing machines shine. The reliability of these machines builds a manufacturer’s reputation by ensuring consistent product quality. Over time, this consistency fosters trust with both direct consumers and large-scale industrial clients, who require assurance that their investments in high-quality cabling are sound. In conclusion, a wire and cable testing machine is not merely a piece of equipment; it is an integral component of quality assurance processes. By harnessing their advanced capabilities, manufacturers can significantly enhance product quality, ensuring competitiveness in a demanding market. The seamless integration of experience, expertise, authoritativeness, and trustworthiness makes these machines invaluable to any manufacturer serious about producing cables that meet and exceed global standards.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy