a traditional tensile tester supplier

Understanding Traditional Tensile Tester Suppliers

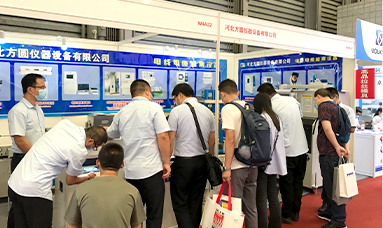

In the realm of material testing, the importance of tensile testers cannot be overstated. These devices serve a crucial role in determining the mechanical properties of materials, particularly their tensile strength, ductility, and elasticity. For manufacturers, engineers, and researchers, understanding the role of traditional tensile tester suppliers is essential for ensuring the quality and reliability of their testing processes.

Traditional tensile testers are used to assess how materials respond to pulling forces. These machines apply a tensile load to a specimen until it breaks, capturing various data points along the way. The results provide insights into how materials will perform under stress, which is vital for applications ranging from construction to aerospace.

Selecting the right tensile tester supplier is critical for obtaining reliable and accurate testing equipment. A reputable supplier should have a robust portfolio of products that cater to different industries and applications. It is essential to consider the specifications of the tensile testers they offer, including load capacity, testing speed, and user interface. Traditional suppliers typically provide equipment that is durable and can withstand rigorous testing environments, ensuring longevity and reliability.

Moreover, a quality supplier will ensure that their tensile testers adhere to international standards and regulations. This adherence is crucial for laboratories and companies that require certifications for quality control processes. Compliance with standards, such as ASTM and ISO, guarantees that the testing methods and results produced are credible and acceptable across global markets.

a traditional tensile tester supplier

One of the benefits of working with traditional tensile tester suppliers is the level of expertise they typically offer. Many established suppliers have years of experience in the industry and can provide valuable insights on the best practices for material testing. They often offer consultation services that help customers select the appropriate testing equipment for their specific needs. This expert knowledge can be invaluable, particularly for businesses that may not have extensive in-house technical expertise.

In addition to supplying testing equipment, leading suppliers often provide after-sales services, including calibration, maintenance, and technical support. Keeping testing equipment in optimal condition is crucial for obtaining accurate results, and a reliable supplier will provide the necessary support to ensure that the equipment functions correctly. This ongoing relationship can save companies time and resources in the long run.

Another aspect to consider when choosing a traditional tensile tester supplier is their approach to innovation. While many suppliers focus on conventional models, the best suppliers also explore new technologies and advancements in testing equipment. This includes the integration of digital systems, data analysis software, and automation features that improve the efficiency and accuracy of testing processes.

Finally, customer service excellence is a hallmark of reputable traditional tensile tester suppliers. Effective communication and responsiveness to inquiries can significantly enhance the purchasing experience. Suppliers who prioritize customer satisfaction typically build long-lasting relationships with their clients, leading to mutual success.

In conclusion, traditional tensile tester suppliers play a pivotal role in the field of material testing. By providing reliable, compliant, and cutting-edge testing equipment, as well as expert support, they enable businesses to ensure the quality and performance of their materials. For anyone involved in material science or engineering, understanding the landscape of traditional tensile tester suppliers is essential for driving innovation and maintaining industry standards.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy