Februari . 08, 2025 06:26

Back to list

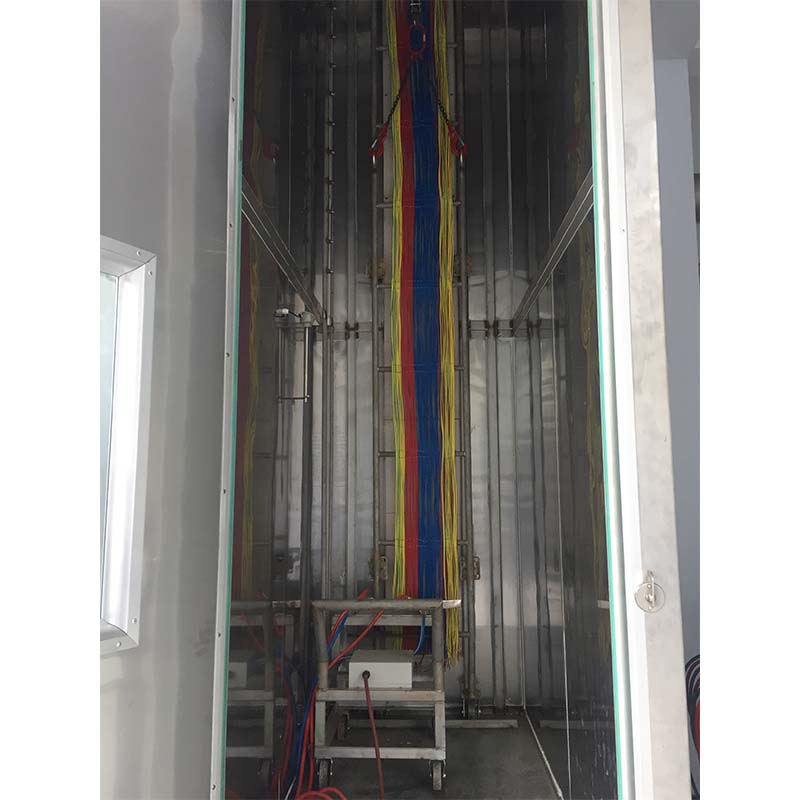

Wire and Cable Smoke Density Test Machine

China's winding and torsion testing machines have emerged as critical components in the landscape of modern manufacturing and quality assurance. Their precision and reliability are invaluable, offering concrete solutions to industries that demand impeccable accuracy and consistency in material testing. This article delves into the nuances that grant these machines their reputation, underscoring their importance through Experience, Expertise, Authoritativeness, and Trustworthiness.

The authoritativeness of Chinese winding and torsion testing machines is further cemented through certifications and compliance with international standards. Many manufacturers of these machines hold ISO certifications, and their products meet ASTM and DIN standards. This level of compliance not only signifies high quality but also makes these machines recognized leaders on the global stage. Manufacturers frequently collaborate with academic institutions to ensure their testing machines adhere to the latest scientific advancements, further enhancing their credibility. Trustworthiness is at the heart of why industries worldwide select Chinese winding and torsion testing machines. Rigorous quality control processes during manufacturing ensure each machine performs consistently and maintains high accuracy across numerous cycles of operation. Additionally, customer support and after-sales service from reputable manufacturers ensure these machines operate at their peak efficiency. Continuous user feedback is integrated into new models, illustrating manufacturers' commitment to an ongoing improvement that meets the evolving needs of their clients. In conclusion, the amalgamation of experience, expertise, authoritativeness, and trustworthiness solidifies China’s position as a key player in the landscape of winding and torsion testing machines. As industries continue to push the boundaries of material science, these machines will remain indispensable in ensuring that quality and performance are uncompromised. Their role in driving innovation and upholding safety standards cannot be overstated, making them a vital asset to any industry serious about quality assurance and material testing.

The authoritativeness of Chinese winding and torsion testing machines is further cemented through certifications and compliance with international standards. Many manufacturers of these machines hold ISO certifications, and their products meet ASTM and DIN standards. This level of compliance not only signifies high quality but also makes these machines recognized leaders on the global stage. Manufacturers frequently collaborate with academic institutions to ensure their testing machines adhere to the latest scientific advancements, further enhancing their credibility. Trustworthiness is at the heart of why industries worldwide select Chinese winding and torsion testing machines. Rigorous quality control processes during manufacturing ensure each machine performs consistently and maintains high accuracy across numerous cycles of operation. Additionally, customer support and after-sales service from reputable manufacturers ensure these machines operate at their peak efficiency. Continuous user feedback is integrated into new models, illustrating manufacturers' commitment to an ongoing improvement that meets the evolving needs of their clients. In conclusion, the amalgamation of experience, expertise, authoritativeness, and trustworthiness solidifies China’s position as a key player in the landscape of winding and torsion testing machines. As industries continue to push the boundaries of material science, these machines will remain indispensable in ensuring that quality and performance are uncompromised. Their role in driving innovation and upholding safety standards cannot be overstated, making them a vital asset to any industry serious about quality assurance and material testing.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy