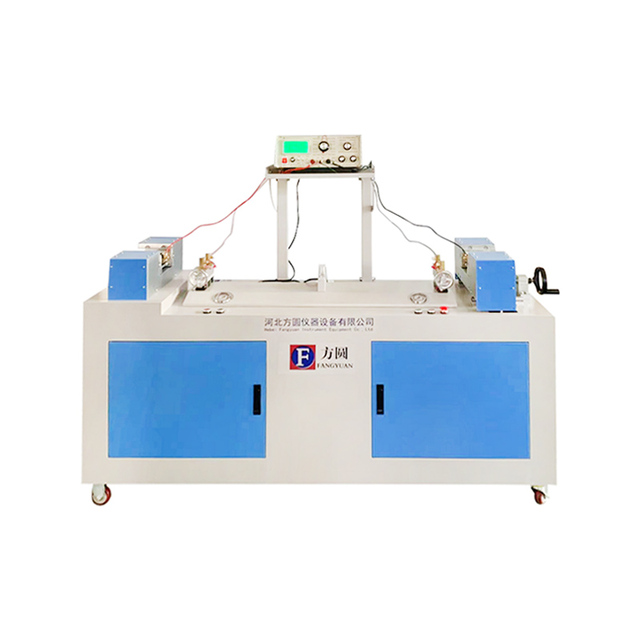

Supplier of Computer-Controlled Tensile Strength Testing Equipment for Accurate Material Analysis

Understanding Computer-Controlled Tensile Strength Testers A Guide for Suppliers

In today's competitive manufacturing landscape, the demand for precision and accuracy in material testing has never been greater. Among various testing methodologies, tensile strength testing plays a pivotal role in evaluating the mechanical properties of materials. As industries rely more on advanced technologies, computer-controlled tensile strength testers have emerged as essential tools for suppliers aiming to provide reliable products and services.

What is a Computer-Controlled Tensile Strength Tester?

A computer-controlled tensile strength tester is an advanced piece of laboratory equipment designed to measure the tensile strength of materials, which is the maximum amount of tensile (stretch) stress that a material can withstand before failing. Unlike traditional mechanical testers, these machines utilize sophisticated computer systems to control the testing process, ensure precision, and collect data automatically.

Features and Benefits

1. Precision and Accuracy One of the main advantages of computer-controlled testers is their ability to deliver highly accurate results. The sensors and software can detect minute changes in material behavior during testing, allowing for detailed analysis.

2. Data Acquisition and Analysis Modern tensile strength testers come equipped with software that enables real-time data collection and analysis. This capability allows suppliers to generate comprehensive reports summarizing the tensile strength, elongation, and other crucial mechanical properties of the tested materials.

3. User-Friendly Interface The user-friendly GUI (Graphical User Interface) of computer-controlled testers simplifies the testing process. Users can easily select testing parameters, conduct tests, and access results without the need for extensive training.

4. Customization Computer-controlled tensile strength testers can be tailored to meet specific testing requirements. Suppliers can choose from various load cells, grips, and environmental chambers to accommodate different materials, including metals, plastics, and textiles.

5. Automation Automation of the testing process increases efficiency and reduces human error. Tests can be programmed to run sequentially, and operators can monitor multiple tests from a single workstation.

Choosing the Right Supplier

computer control tensile strength tester supplier

When selecting a computer-controlled tensile strength tester, it's crucial to consider the following factors to ensure that the supplier meets your needs

1. Quality and Reliability Look for suppliers with a proven track record in delivering high-quality testing equipment. Customer reviews and industry reputation can provide useful insights.

2. Technical Support A reliable supplier should offer robust technical support and training for their equipment. This assistance is essential for ensuring that users are well-equipped to utilize the machinery effectively.

3. Calibration and Maintenance Ensuring the accuracy of tensile strength testers requires regular calibration and maintenance. Choose a supplier that provides these services as part of their offering to sustain the performance of the equipment.

4. Customization Options Since different materials may require specific testing setups, a supplier that offers customization options will ensure that you get a machine tailored to your specific needs.

5. Cost-Effectiveness While it's important to invest in quality equipment, consider the overall value. Compare specifications and features across different suppliers to find a balance between cost and capability.

The Future of Material Testing

As technology continues to advance, the role of computer-controlled tensile strength testers will expand and evolve. Innovations in artificial intelligence and machine learning may lead to even more sophisticated testing methods that not only measure material properties but also predict behavior under various conditions.

Conclusion

Suppliers of computer-controlled tensile strength testers play a vital role in supporting industries that rely on material integrity and performance. By investing in advanced testing equipment, suppliers can ensure that they meet stringent quality standards, attract more clients, and build a reputation for reliability in the marketplace. The future looks promising for those who embrace the power of technology in material testing.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy