Determining Resistance in Custom Conductors Through Detailed Testing Methods

Understanding Custom Conductor Resistance Testing A Comprehensive Overview

In the realm of electrical engineering, ensuring the integrity and performance of conductors is paramount. One of the critical parameters that engineers must evaluate is the resistance of these conductors. Custom conductor resistance testing is a method designed to assess the electrical resistance of various conductor types under specific conditions. This article delves into the importance, methodology, and implications of custom conductor resistance testing.

Importance of Conductor Resistance Testing

Conductors are pivotal components in electrical systems, used to transport electricity from one point to another. The efficiency of power transmission relies significantly on the conductor’s resistance. High resistance can lead to energy losses in the form of heat, impacting system performance and reliability. Therefore, custom conductor resistance testing is essential to ensure that conductors meet industry standards and can operate efficiently in their respective applications.

Moreover, different applications might require different testing criteria. For example, conductors used in renewable energy systems may need to adhere to stricter standards to ensure reliability in harsh environments. Custom testing allows engineers to tailor their assessments, ensuring that the conductors can withstand specific conditions and perform optimally.

Methodology of Custom Conductor Resistance Testing

The process of custom conductor resistance testing involves several steps. First, the engineer must define the requirements based on the intended application of the conductor. This includes determining the environmental conditions, the electrical load, and any regulatory standards that must be met.

Once the parameters are set, the testing process begins. Commonly, the four-wire or Kelvin method is employed, which minimizes the effect of lead resistance. This involves using two wires to carry the current and two additional wires to measure the voltage drop across the conductor. The resistance is then calculated using Ohm’s Law (R = V/I), where R is resistance, V is voltage, and I is the current.

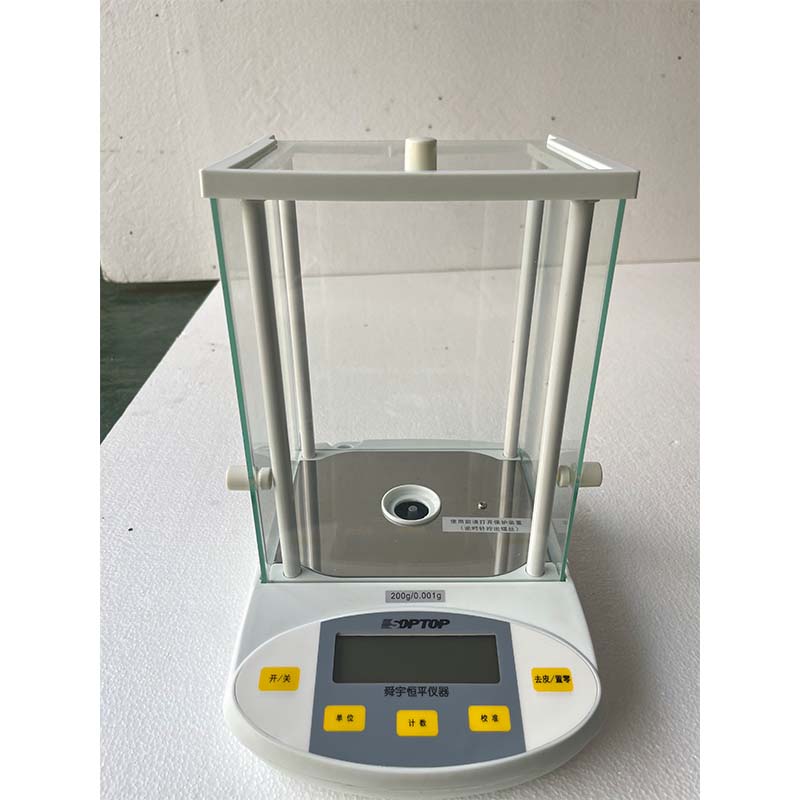

custom conductor resistance test

For custom testing, additional considerations might include temperature corrections, as resistance can fluctuate with temperature changes. Engineers often refer to standardized tables or use specialized software to account for these variations, ensuring the test results are accurate and reflective of real-world conditions.

Implications of the Results

The results obtained from custom conductor resistance testing are vital for several reasons. Firstly, they enable engineers to identify conductors that do not meet the necessary criteria, allowing for remediation strategies to be implemented before installation or operation. This can prevent potential failures, enhance safety, and reduce downtime in electricity distribution systems.

Secondly, the data can inform design improvements. If certain conductors consistently show higher resistance, engineers may investigate alternative materials or designs that could enhance performance. This iterative process of testing and improvement contributes to advancing technology within the electrical industry.

Finally, detailed records of resistance tests can assist in compliance with regulatory requirements and standards, providing documented proof that conductors have been appropriately evaluated under custom conditions. This adds an extra layer of assurance for stakeholders, from manufacturers to end-users, promoting confidence in the electrical infrastructure.

Conclusion

Custom conductor resistance testing plays a vital role in the electrical engineering domain, ensuring that conductors are capable of performing under specified conditions and standards. By tailoring tests to meet the unique demands of various applications, engineers can safeguard against inefficiencies and failures, ultimately contributing to the reliability and performance of electrical systems. As technology advances and the need for efficient energy transmission grows, the importance of thorough and custom testing will only continue to increase.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy