Evaluation of Fabric Tensile Strength Using Advanced Testing Methods

Understanding Tensile Strength Testing of Fabrics

Tensile strength is a critical parameter in the textile industry, particularly when it comes to evaluating the performance and durability of various fabrics. Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can withstand before failing or breaking. In the context of fabrics, this property is essential not only for determining the usability of textiles in different applications but also for ensuring safety and quality in finished products.

Understanding Tensile Strength Testing of Fabrics

To conduct a tensile strength test, a sample piece of fabric is prepared, usually cut into a standardized size. The fabric tester grips the sample at both ends and gradually applies a force that pulls the fabric apart. During this process, the machine measures both the force applied and the elongation of the fabric until the sample breaks. The results are then recorded and analyzed, typically expressed in terms of force per unit width (like Newtons per millimeter or pounds per inch).

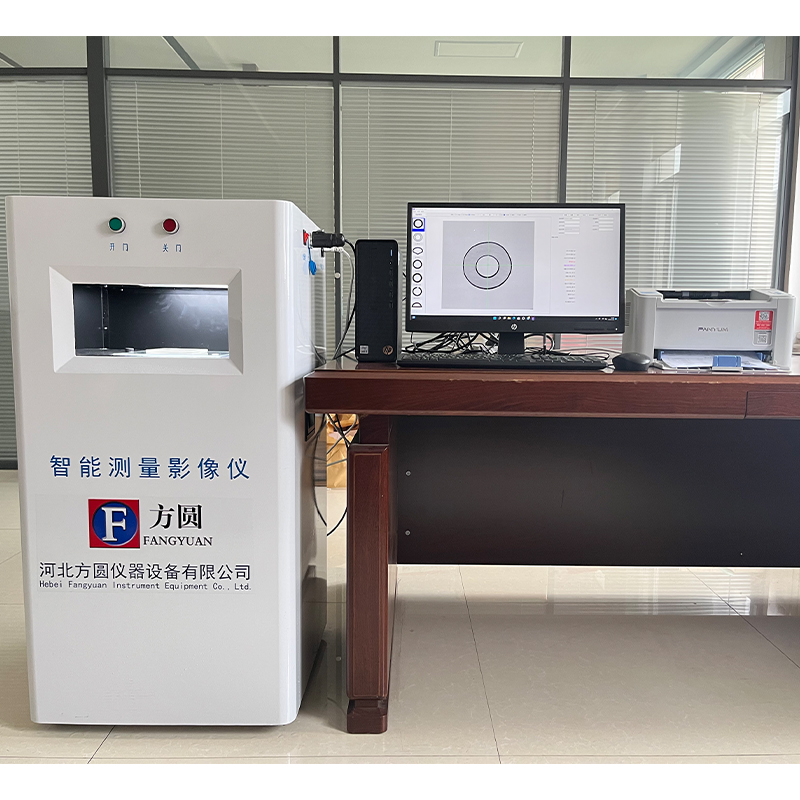

tensile strength of fabric tester

The importance of tensile strength testing cannot be overstated. It helps manufacturers assess the quality of their fabrics, providing insights into how the material will perform under stress. For instance, fabrics intended for heavy-duty applications, such as upholstery and outdoor gear, require higher tensile strength compared to those used for lighter applications, such as fashion garments or bed linens.

Additionally, understanding tensile strength can influence the design and development of new fabrics. By experimenting with different weaving techniques, fiber compositions, and treatments, manufacturers can enhance the tensile properties of their products. This is particularly important in industries where performance is key, such as sportswear or safety gear. Fabrics with higher tensile strength can improve the longevity and reliability of a product, leading to increased customer satisfaction and reduced return rates.

Another critical aspect of tensile strength testing is its role in compliance with industry regulations and safety standards. Certain applications, like automotive interiors or construction materials, necessitate fabrics that meet specific tensile strength requirements to ensure consumer safety. Regular testing ensures that products not only comply with these regulations but also perform effectively under real-world conditions.

In conclusion, tensile strength testing of fabrics is a fundamental practice in the textile industry, ensuring that materials meet the necessary performance criteria for their intended applications. By examining how fabrics respond to tension, manufacturers can enhance product quality, safety, and longevity. As the industry continues to evolve, ongoing advancements in testing technology and methodologies will further refine our understanding of fabric properties, leading to innovative designs and improved textile performance. Ultimately, the ability to accurately measure tensile strength empowers manufacturers to create fabrics that not only meet but exceed consumer expectations, driving the growth of the textile market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy