Hydraulic Conductor Resistance Testing Equipment for Manufacturing and Quality Assurance

The Importance of Hydraulic Conductor Resistance Fixture Factories in the Modern Industry

In the ever-evolving landscape of industrial manufacturing, the role of hydraulic systems is paramount. Among the many components that ensure these systems function efficiently, hydraulic conductor resistance fixtures have emerged as critical devices. These fixtures help in measuring and calibrating hydraulic systems, contributing significantly to the effectiveness and reliability of hydraulic applications. Manufacturing these sophisticated devices involves specialized factories committed to precision engineering and quality assurance.

Understanding Hydraulic Conductor Resistance Fixtures

Hydraulic conductor resistance fixtures are designed to test the resistance and performance of hydraulic conduits under varying pressures and conditions. By simulating real-world scenarios, these fixtures ensure that hydraulic systems can operate safely and efficiently. This testing is crucial, as failures in hydraulic systems can lead to significant operational downtime and safety hazards in industries ranging from automotive to aerospace.

Role of Factories in Manufacturing

The production of hydraulic conductor resistance fixtures requires a combination of advanced technology and skilled craftsmanship. Factories dedicated to manufacturing these fixtures invest in high-quality materials, precision machining processes, and rigorous testing protocols. The manufacturing process typically involves several key steps

1. Design and Engineering The initial phase involves designing fixtures that meet specific industry standards and requirements. Engineers use advanced computer-aided design (CAD) software to create detailed models, ensuring that every component can withstand the stresses of hydraulic testing.

2. Material Selection The choice of materials is crucial. Hydraulic fixtures must resist corrosion and wear, and manufacturers often utilize high-grade stainless steel or specialized alloys. Selection of appropriate materials also enhances the longevity and durability of the fixtures.

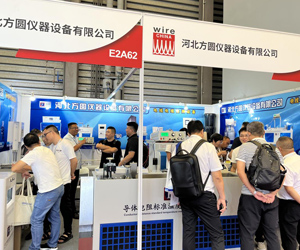

hydraulic conductor resistance fixture factories

3. Precision Machining After material selection, factories employ precision machining techniques such as CNC (Computer Numerical Control) milling and turning. These processes allow for the exacting standards required to manufacture components with tight tolerances—essential for accurate resistance measurements.

4. Assembly and Calibration Once individual components are produced, they are meticulously assembled. This stage often includes calibrating the fixtures to ensure that they produce consistent and reliable readings. Factory technicians use sophisticated instruments to validate the performance of each fixture before it leaves the facility.

5. Quality Control Quality assurance is a cornerstone of manufacturing hydraulic conductor resistance fixtures. Factories implement rigorous testing procedures to evaluate the durability and effectiveness of the fixtures. This may involve subjecting them to extreme pressure conditions and checking for leaks or inaccuracies in measurements.

The Market Demand for Hydraulic Fixtures

With the continuous growth of industries dependent on hydraulic systems, the demand for high-quality hydraulic conductor resistance fixtures is on the rise. Industries such as construction, manufacturing, and even renewable energy rely heavily on precision hydraulic systems. As automation and efficiency become increasingly vital, the role of testing and calibration equipment like hydraulic fixtures becomes more pronounced.

Moreover, with the advent of Industry 4.0, factories are looking to integrate smart technology into their manufacturing processes. This includes the use of IoT (Internet of Things) devices to monitor machine performance and condition in real-time, potentially leading to predictive maintenance and reduced downtime.

Conclusion

The factories producing hydraulic conductor resistance fixtures play a vital role in ensuring the reliability and safety of hydraulic systems across various industries. By combining advanced engineering, quality materials, and rigorous testing protocols, these manufacturers contribute to the overall efficiency and effectiveness of hydraulic applications. As industries continue to evolve, the importance of high-quality hydraulic testing equipment will only increase, underscoring the significance of these specialized factories in the modern industrial landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy