Leading Manufacturers of Tensile Strength Testing Equipment for Quality Assurance

The Role of Tensile Strength Tester Manufacturers in Quality Assurance

In today's fast-paced industrial landscape, the demand for high-quality materials is paramount. Organizations across various sectors, including construction, manufacturing, and aerospace, rely heavily on the mechanical properties of materials to ensure the safety and durability of their products. Among these properties, tensile strength— the capacity of a material to withstand stretching forces—stands out as a critical measure. To assess this property accurately, tensile strength testers are indispensable tools. Consequently, the role of tensile strength tester manufacturers becomes pivotal in both quality assurance and product innovation.

Understanding Tensile Strength

Tensile strength is a fundamental mechanical property that indicates how much load a material can bear before failing. This characteristic is particularly important for materials like metals, plastics, and composites, which are widely utilized across different industries. By determining the tensile strength of a material, manufacturers can predict its behavior under stress, ensuring that the products they create will perform reliably under real-world conditions.

The Manufacturing Process

Tensile strength testers come in various configurations, including electronic and mechanical models. The manufacturing process for these devices involves sophisticated engineering and quality control measures. Manufacturers must ensure that every component of the tester, from the loading mechanism to the measurement sensors, is designed to provide accurate and repeatable results.

Many manufacturers utilize advanced technology such as computerized axial testing (CAT) systems. These systems incorporate digital data collection and analysis, which enhances the precision of the tests being conducted. Additionally, employing high-grade materials during the manufacturing process contributes to the longevity and reliability of the testers.

Ensuring Quality Through Standards

Quality control is an ongoing concern for tensile strength tester manufacturers. Many adhere to international standards set by organizations such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). Compliance with these standards is crucial, as it guarantees that the testers are capable of producing accurate results that users can rely on worldwide.

tensile strength tester manufacturers factory

Manufacturers of tensile strength testers often undergo rigorous testing themselves to comply with these standards. This includes ambient condition tests, calibration checks, and validation procedures to ensure the equipment's accuracy over time. This commitment to quality ensures that their customers can trust the results obtained from their testing equipment.

Customization and Innovation

As industries evolve and new materials are developed, the need for customized testing solutions increases. Leading tensile strength tester manufacturers are recognizing this trend and are often willing to collaborate with clients to develop tailored testing equipment that meets specific requirements. Custom solutions can involve altering the design of the tester, adding specialized grips for certain materials, or integrating software that caters to unique data analysis demands.

Innovation is also a significant focus area for these manufacturers. With the advent of Industry 4.0, many tensile strength testers now incorporate smart technology that allows for real-time monitoring and remote data analysis. This capability not only streamlines the testing process but also enhances the overall efficiency and accuracy of material evaluations.

The Future of Tensile Strength Testing

Looking ahead, tensile strength tester manufacturers are likely to continue evolving in response to the changing needs of industries. Areas such as automation, data analytics, and user-friendly interfaces are becoming increasingly important. As industries place greater emphasis on sustainability and recycling, manufacturers may also need to focus on testing methods suitable for recycled materials and biocomposites, which are gaining popularity.

Conclusion

In conclusion, tensile strength tester manufacturers play a vital role in the global supply chain by providing essential equipment that ensures the quality and integrity of materials used in various applications. Through meticulous manufacturing processes, adherence to rigorous standards, and a commitment to innovation, these manufacturers contribute significantly to the safety and performance of products across multiple sectors. As technologies advance and industry demands evolve, the partnership between manufacturers and their clients will be crucial in shaping the future of material testing.

-

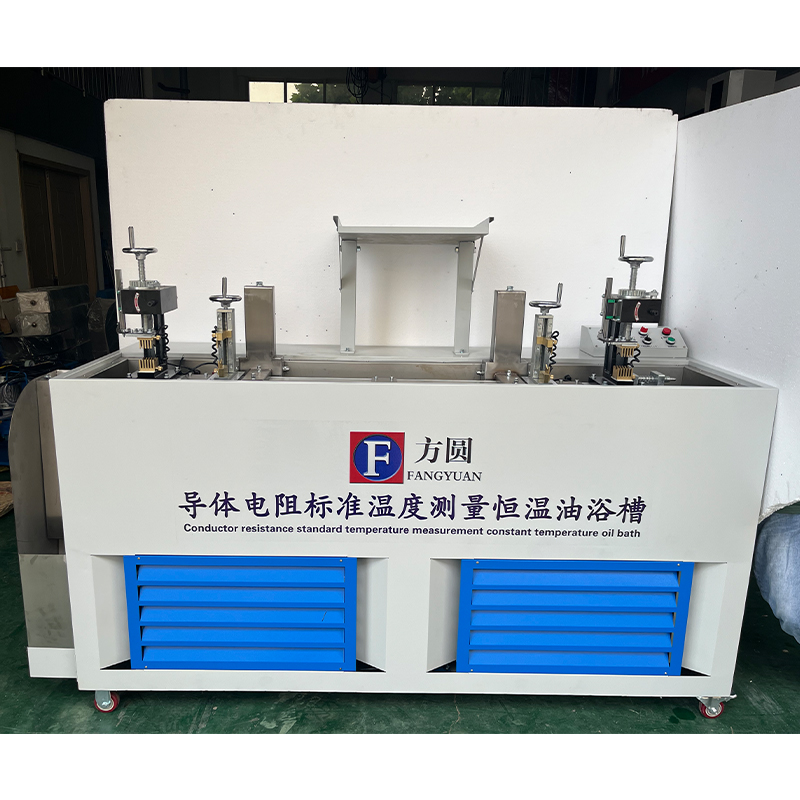

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy