Universal Resistance Testing Fixture Supplier for Accurate Performance Evaluation and Quality Assurance

Universal Resistance Fixture Manufacturer The Backbone of Quality Testing

In the realm of manufacturing and quality control, resistance fixtures play a pivotal role in ensuring that products meet the required safety and performance standards. A universal resistance fixture manufacturer specializes in creating devices that can efficiently assess the electrical resistance of various products. These fixtures are integral in sectors such as electronics, automotive, aerospace, and more, where even minor inconsistencies can lead to major failures. This article delves into the significance of universal resistance fixture manufacturers and the impact they have on industries worldwide.

Understanding Resistance Fixtures

Resistance fixtures are devices used to measure the electrical resistance of materials and components. The measurement of resistance is critical in various applications, including circuit testing, component quality assurance, and safety evaluations. A universal resistance fixture is designed to accommodate a wide range of test specimens while offering accurate and reliable measurements. As technology advances, the need for sophisticated and versatile testing equipment has grown, driving the demand for innovative and adaptable resistance fixtures.

Key Features of Universal Resistance Fixtures

1. Versatility Universal resistance fixtures are designed to test different types of materials and components. This flexibility is crucial for manufacturers who produce various products, enabling them to use a single fixture for multiple applications.

2. Accuracy Precision is paramount when measuring electrical resistance. High-quality resistance fixtures are engineered to provide accurate readings, ensuring that manufacturers can trust the results. This reliability helps in maintaining product quality and complying with industry standards.

3. Ease of Use Modern resistance fixtures often feature intuitive designs and user-friendly interfaces, allowing technicians to operate them with minimal training. This ease of use increases efficiency in testing processes, reducing downtime and labor costs.

4. Durability Given their role in rigorous testing environments, universal resistance fixtures must be built to withstand wear and tear. A reputable manufacturer will use high-quality materials and robust construction methods to ensure longevity.

5. Customization Different industries have unique testing requirements. A top-tier universal resistance fixture manufacturer can provide customized solutions tailored to the specific needs of their clients, enhancing the testing process's effectiveness.

universal resistance fixture manufacturer

Importance of Collaboration with a Reliable Manufacturer

Choosing the right universal resistance fixture manufacturer is critical for any business involved in testing and quality assurance. An experienced manufacturer understands the nuances of testing requirements across different sectors and can provide insights into the best practices for utilizing their equipment. Here are some factors to consider when selecting a manufacturer

1. Reputation Look for manufacturers with a proven track record in the industry. Customer reviews, case studies, and certifications can provide insight into the reliability and quality of their products.

2. Technical Support A good manufacturer offers excellent customer service and technical support. This assistance is invaluable for addressing any issues that may arise during the testing process.

3. Innovation The rapidly changing landscape of technology necessitates that manufacturers stay ahead of the curve. A manufacturer committed to innovation will continually update their designs and functionalities to meet evolving industry standards.

4. Compliance Ensure that the manufacturer adheres to relevant industry standards and regulations. Compliance with safety and quality benchmarks is essential for maintaining product integrity and avoiding legal liabilities.

5. Cost-Effectiveness While price is an important factor, it should not be the sole consideration. Evaluate the overall value that a manufacturer provides, including product quality, durability, and customer service, to make an informed decision.

Conclusion

The role of universal resistance fixture manufacturers in the manufacturing landscape cannot be overstated. They provide the tools necessary for ensuring the safety and performance of products across various industries. By prioritizing accuracy, versatility, and durability, these manufacturers contribute significantly to the quality assurance processes that protect businesses and consumers alike. In an increasingly competitive market, partnering with a reliable manufacturer can help businesses achieve excellence in quality control, ultimately leading to enhanced customer satisfaction and loyalty. As technology continues to evolve, so will the importance of universal resistance fixture manufacturers in meeting the demands of modern industry. Investing in high-quality resistance fixtures today will pay dividends in reliability and performance for years to come.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

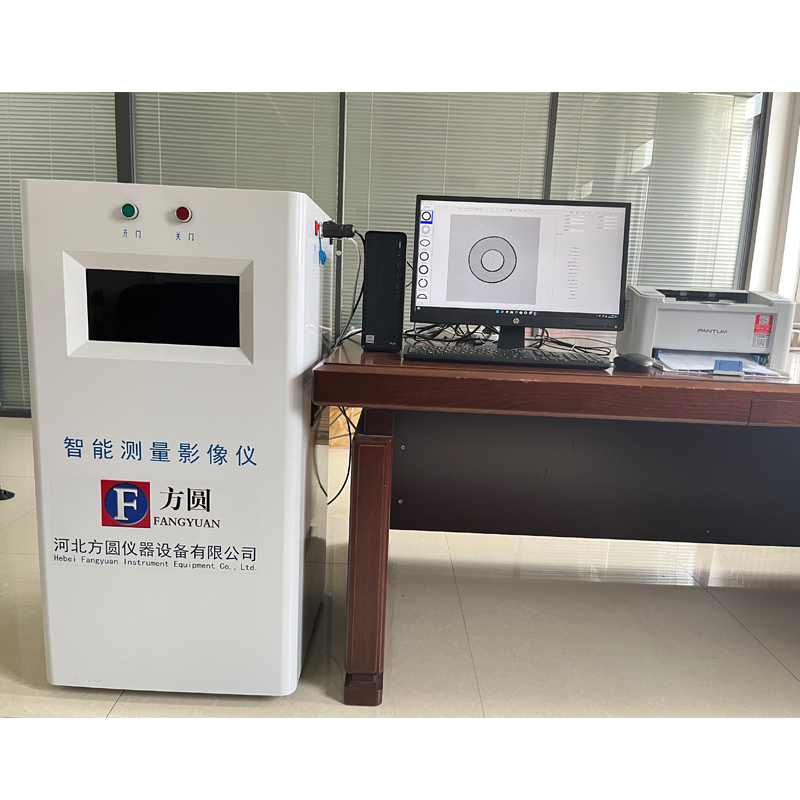

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy