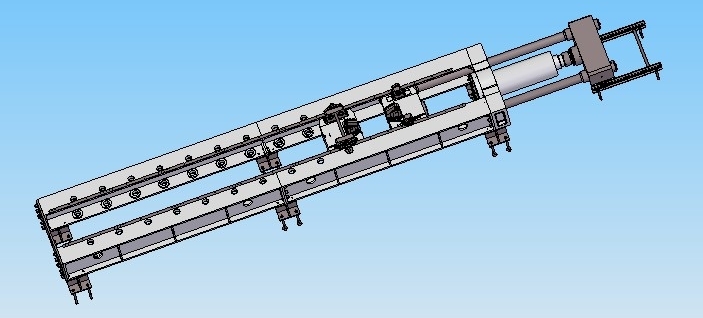

TXWL-600 Electro-Hydraulic Servo Horizontal Tensile Test Machine

Maelezo ya bidhaa

TXWL-600 electro-hydraulic servo usawa kupima tensile mashine inachukua muundo wa sura ya usawa, fimbo moja-kaimu pistoni silinda inatoa nguvu ya mtihani, na mfumo wa udhibiti wa kompyuta inatambua udhibiti wa moja kwa moja wa mchakato wa mtihani kwa kudhibiti servo valve na vipengele vingine, mtihani. data inakusanywa kwa usahihi na kitambuzi cha upakiaji na kutumwa kwa kompyuta, mfumo huchanganua kiotomatiki, kuchakata na kuhifadhi matokeo ya majaribio, na kichapishi kinaweza kuchapisha moja kwa moja ripoti ya jaribio inayohitajika. Mashine hii hutumiwa hasa kwa ajili ya mtihani wa mvutano wa kamba ya waya ya chuma, ni uzalishaji wa kisasa wa utafiti wa kisayansi na mafundisho na viwanda vingine ili kukidhi mahitaji ya vifaa vya mtihani bora.

Maelezo ya Mashine

1.Mfumo wa mwenyeji

Sehemu kuu ya mashine inaundwa na sura kuu ya mashine, kiti cha silinda ya mafuta, silinda ya mafuta, boriti inayosonga, kiti cha mbele na nyuma cha chuck na sensor ya mzigo. Inaweza kufanya mtihani wa mvutano na mzigo wa juu wa 600kN kwenye sampuli.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Eneo la mtihani lina vifaa vya kifuniko cha kinga, ambacho kinaweza kulinda usalama wa wafanyakazi wa mtihani.

2.Mfumo wa chanzo cha mafuta

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Sehemu ya Umeme

Udhibiti wa umeme umepangwa katika eneo la operesheni ya majaribio, na kuna jopo la operesheni iliyoundwa maalum ili kufanya kila aina ya shughuli kuwa wazi kwa mtazamo. Vipengele vya umeme ni vya chapa maarufu ya kimataifa, na utendaji thabiti na ubora wa kuaminika.

Mfumo wa Programu:

(1) Kulingana na jukwaa endeshi la Windows XP lenye vitendaji vinavyoweza kuratibiwa, udhibiti wa nguvu ya mtihani wa kiwango sawa, udhibiti wa uhamishaji wa viwango sawa, ushikiliaji wa nguvu ya majaribio, ushikiliaji wa uhamishaji na njia zingine za majaribio zinaweza kuunganishwa kwa hiari ili kukidhi mahitaji ya mbinu mbalimbali za majaribio. kwa kiwango cha juu zaidi, na kutambua maonyesho mbalimbali ya data, kuchora curve, usindikaji wa data, uhifadhi na vitendaji vya uchapishaji vinavyohitajika kwa ajili ya jaribio.

(2) Tuma ishara ya udhibiti kwa valve ya servo kupitia kompyuta ili kudhibiti ufunguzi na mwelekeo wa valve ya servo, na hivyo kudhibiti mtiririko kwenye silinda, na kutambua udhibiti wa nguvu ya mtihani wa kiwango sawa, uhamishaji wa kiwango sawa, nk. .

(3) Iliyo na vitanzi viwili vya kudhibiti vilivyofungwa vya nguvu ya majaribio na uhamishaji.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) Kiolesura kuu kina kazi zote za uendeshaji wa kila siku wa jaribio, kama vile uingizaji wa taarifa za sampuli, uteuzi wa sampuli, kuchora curve, kuonyesha data, usindikaji wa data, uchambuzi wa data, uendeshaji wa mtihani, nk. Operesheni ya mtihani ni rahisi na haraka.

(6) Data inaweza kutolewa kwa kichapishi ili kuchapisha ripoti ya jaribio.

(7) Mfumo wa usimamizi wa kihierarkia, vigezo vya mfumo vyote viko wazi kwa watumiaji wa kitaalam, kuhakikisha kubadilika na kuegemea kwa mfumo.

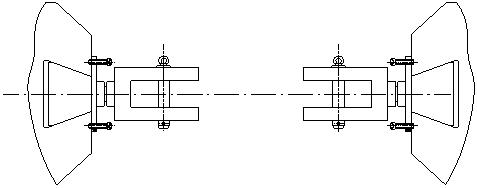

4.Vifaa vya Mtihani

Zikiwa na vifaa vya majaribio ya kamba ya waya (tazama hapa chini) na vifaa vingine vinatengenezwa kulingana na kiwango kilichotolewa na mtumiaji au mahitaji ya mkazo ya sampuli.

5.Vifaa vya Ulinzi wa Usalama

(1) Ulinzi wa upakiaji wakati nguvu ya majaribio inazidi 2% hadi 5% ya nguvu ya juu ya mtihani au thamani iliyowekwa.

(2) Kinga ya kiharusi wakati bastola inasogea hadi nafasi ya kikomo.

(3) Kwa joto la mafuta, kiwango cha kioevu na ulinzi wa upinzani wa mafuta na vifaa vya dalili.

(4) Nafasi ya majaribio ina kifuniko cha kinga ili kuzuia sampuli isipasuke na kudondoka.

(5) Dharura inapotokea, bonyeza kitufe cha kusitisha dharura kwenye baraza la mawaziri la kudhibiti moja kwa moja

Kigezo cha Kiufundi

1.Nguvu ya juu zaidi ya majaribio: 600kN

2.Aina ya kipimo cha nguvu ya majaribio: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.Nafasi ya kupima mkazo (bila kujumuisha kiharusi cha pistoni): 20mm ~ 12000mm

5.Pistoni kiharusi: 1000mm

6.Upeo wa kasi ya kazi ya pistoni: 100 mm / min

7.Deformation extensometer usahihi: 0.01mm

8.Kipimo cha mashine kuu(mm): 16000(L) x 1300(W) x 1000(H) (bila kujumuisha kifuniko cha kinga)