Cable Sheath Cutting Tools and Equipment Manufacturers for Efficient Wire Processing

The Role of Cable Outer Sheath Cutter Factories in Modern Industry

In the ever-evolving landscape of manufacturing and telecommunications, the demand for efficient cable management solutions is at an all-time high. One of the critical tools in this domain is the cable outer sheath cutter. As technology advances and the necessity for organized cabling systems increases, cable outer sheath cutter factories have positioned themselves as integral players in the supply chain, providing essential tools that streamline operations and enhance productivity.

Understanding Cable Sheath Cutters

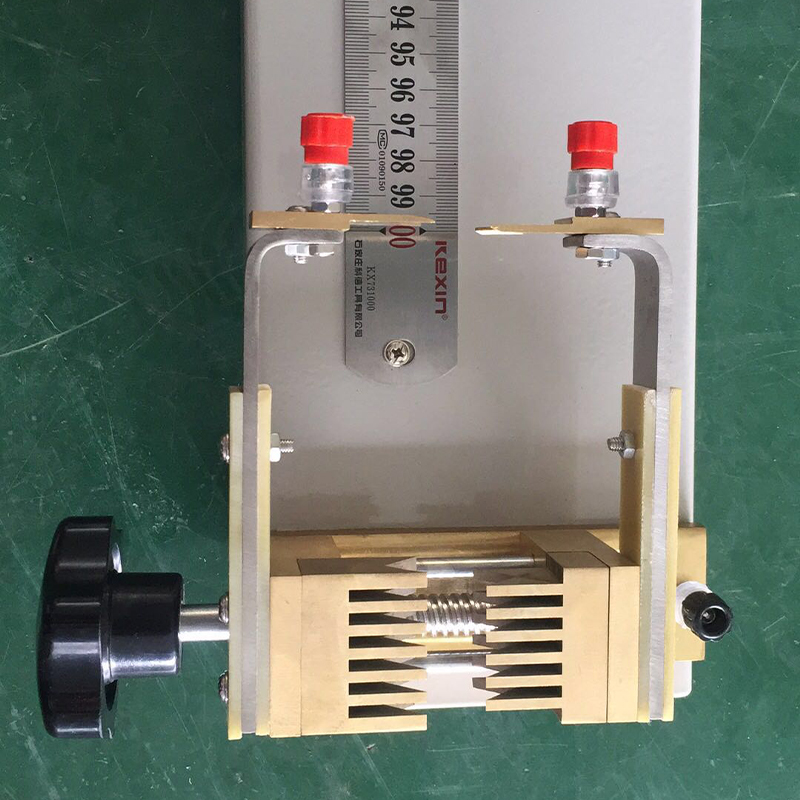

Cable outer sheath cutters are specialized tools designed to effectively remove the protective outer covering of electrical cables. These sheaths are typically made of materials such as plastic or rubber, which insulate the electrical wires and protect them from environmental factors. The process of cutting these sheaths requires precision and skill, as improper cuts can damage the wires inside, leading to safety hazards and operational inefficiencies.

The design of cable sheath cutters varies, from manual handheld devices to advanced automatic machinery used in large-scale production environments. Features often include ergonomic handles, adjustable cutting depths, and safety mechanisms to protect users during operation. Factories dedicated to the production of these tools focus on innovation and ergonomics, ensuring that their products meet the demanding standards of various industries.

The Importance of Cable Sheath Cutter Factories

1. Meeting Industry Demands As industries such as telecommunications, construction, and electronics continue to grow, the need for efficient cable management solutions becomes more pronounced. Factories that specialize in producing cable outer sheath cutters are essential in meeting the increased demand. By providing tools that enhance the efficiency of cable installation and maintenance, these factories support the overall productivity of various sectors.

cable outer sheath cutter factories

2. Innovation and Technology The advancement of technology has significantly impacted the manufacturing of cable sheath cutters. Modern factories leverage cutting-edge techniques, such as automation, CNC machining, and material science, to produce high-quality tools. This innovative approach not only improves the precision and durability of the cutters but also reduces production costs, ultimately benefiting end-users.

3. Quality Control Cable outer sheath cutters must adhere to strict quality standards to ensure safety and reliability. Factories invest in comprehensive quality control processes, from the selection of raw materials to the final inspection of finished products. Rigorous testing is conducted to assess the cutters' performance and durability, ensuring that they can withstand the rigors of daily use in various environments.

4. Customization Different industries have unique requirements when it comes to cable types and sizes. Many cable outer sheath cutter factories offer customization options, allowing clients to order tools tailored to their specific needs. This flexibility ensures that users can select the right tool for their application, enhancing efficiency and reducing the risk of damage during use.

5. Sustainability Practices Increasingly, consumers and companies are prioritizing sustainability. Factories producing cable sheath cutters are adopting eco-friendly practices, such as utilizing recyclable materials and implementing energy-efficient manufacturing processes. This commitment to sustainability resonates with consumers and enhances the overall brand reputation of the manufacturers.

The Future of Cable Outer Sheath Cutter Factories

As technology continues to advance, the future of cable outer sheath cutter factories looks promising. With the rise of smart technology, there is potential for the development of intelligent cutting systems that can adapt to various cable types and sizes automatically. Additionally, the continuous improvement in materials will likely lead to lighter, stronger, and more durable cutters, further enhancing user experience.

In conclusion, cable outer sheath cutter factories play a crucial role in ensuring that industries have access to efficient and reliable tools for cable management. By focusing on innovation, quality, customization, and sustainability, these factories not only meet the current demands of the market but also pave the way for future advancements in cable assembly and maintenance. Given the growing dependence on technology across various sectors, the importance of these factories is set to increase, making them an indispensable part of the industry’s infrastructure.

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy