ஜன . 15, 2025 03:30

Back to list

cable smoke density test machine company

The cable vertical burning test machine is an essential piece of equipment in the realm of fire safety testing, providing a critical assessment of cable insulation materials' flammability and fire resistance. From industry experience, this machine plays a pivotal role in ensuring electrical products meet stringent safety standards.

A pivotal aspect of this machine is the trustworthiness of its data, hinging on meticulous calibration and maintenance. Regular calibration ensures that results are consistent across different batches and brands, offering manufacturers and consumers reliability in the safety ratings. Maintenance protocols are essential to preserving the integrity of the machine, including regular inspection of the burner, airflow systems, and data recording instruments. Engaging with this machine brings certain challenges. From my authentic experiences, ensuring the operator's expertise is as crucial as the machine's technical specifications. Skilled technicians are required to interpret the results accurately and make informed judgments about material performance and conformity with safety standards. Looking towards the future, advancements in digital technology are poised to transform the cable vertical burning test machine. The integration of advanced sensors and IoT platforms promises enhanced data analytics capabilities, offering deeper insights into fire resistance data. This evolution will further bolster its position as an authoritative tool in the industry, ensuring cables not only meet legal standards but surpass them, contributing to overall fire safety. In conclusion, the cable vertical burning test machine stands as a cornerstone in electrical safety testing, embodying experience, expertise, authoritativeness, and trustworthiness. Its continued evolution and application are critical in the pursuit of safety and innovation within the electrical manufacturing sector. Whether you're a manufacturer, safety inspector, or regulatory body, understanding its operation and outputs is crucial in advancing product reliability and consumer safety.

A pivotal aspect of this machine is the trustworthiness of its data, hinging on meticulous calibration and maintenance. Regular calibration ensures that results are consistent across different batches and brands, offering manufacturers and consumers reliability in the safety ratings. Maintenance protocols are essential to preserving the integrity of the machine, including regular inspection of the burner, airflow systems, and data recording instruments. Engaging with this machine brings certain challenges. From my authentic experiences, ensuring the operator's expertise is as crucial as the machine's technical specifications. Skilled technicians are required to interpret the results accurately and make informed judgments about material performance and conformity with safety standards. Looking towards the future, advancements in digital technology are poised to transform the cable vertical burning test machine. The integration of advanced sensors and IoT platforms promises enhanced data analytics capabilities, offering deeper insights into fire resistance data. This evolution will further bolster its position as an authoritative tool in the industry, ensuring cables not only meet legal standards but surpass them, contributing to overall fire safety. In conclusion, the cable vertical burning test machine stands as a cornerstone in electrical safety testing, embodying experience, expertise, authoritativeness, and trustworthiness. Its continued evolution and application are critical in the pursuit of safety and innovation within the electrical manufacturing sector. Whether you're a manufacturer, safety inspector, or regulatory body, understanding its operation and outputs is crucial in advancing product reliability and consumer safety.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

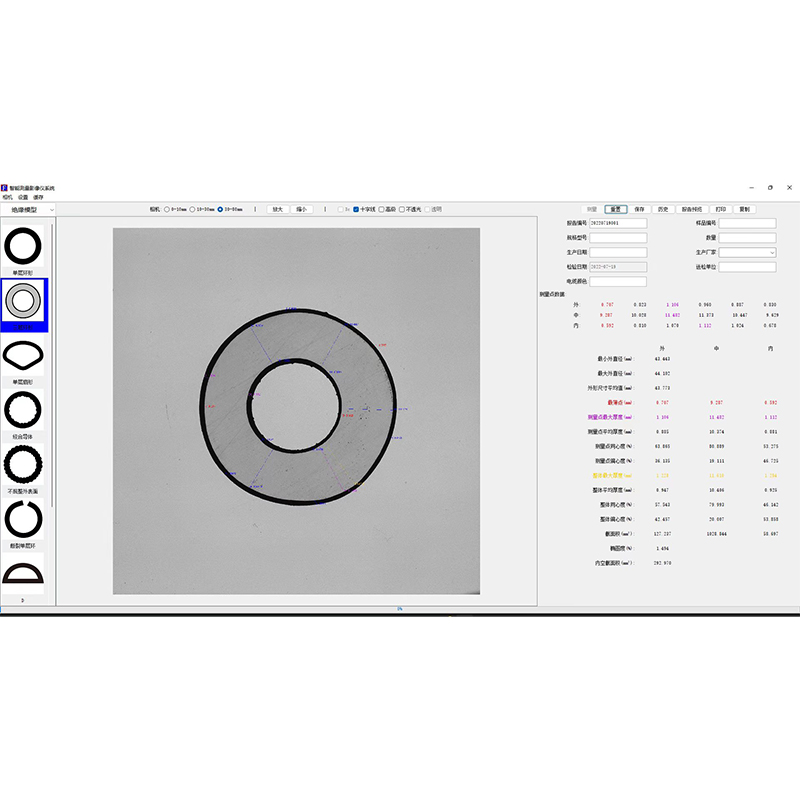

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

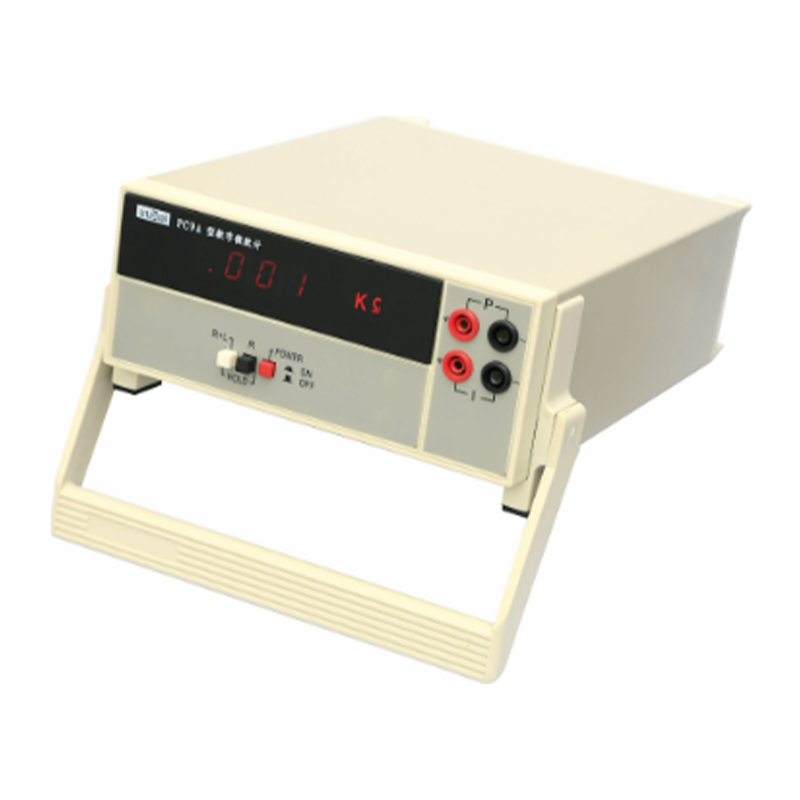

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy