measure machine for cables companies

Measuring Machines for Cable Companies Enhancing Precision and Efficiency

In the world of manufacturing, precision is paramount, especially in industries like cable production. Cable companies must ensure that their products meet stringent quality standards to ensure safety and reliability. As the demand for high-quality cables continues to rise, the need for advanced measuring machines becomes essential. These machines play a vital role in enhancing both the quality and efficiency of production processes.

The Importance of Measurement in Cable Manufacturing

Cable manufacturing involves intricate processes that require careful monitoring of various parameters, including length, diameter, insulation thickness, and electrical properties. Accurate measurements are crucial because even minor discrepancies can lead to significant issues during installation and operation. For manufacturers, this means that having the right measuring machines is not just a matter of compliance but also a competitive advantage.

Types of Measuring Machines in Cable Production

1. Laser Measurement Systems Laser-based systems offer highly accurate measurements for cable length and diameter. They work by emitting laser beams that reflect off the surface of the cable, allowing for instantaneous calculation of distances and sizes. This technology reduces human error and increases the speed of the measurement process.

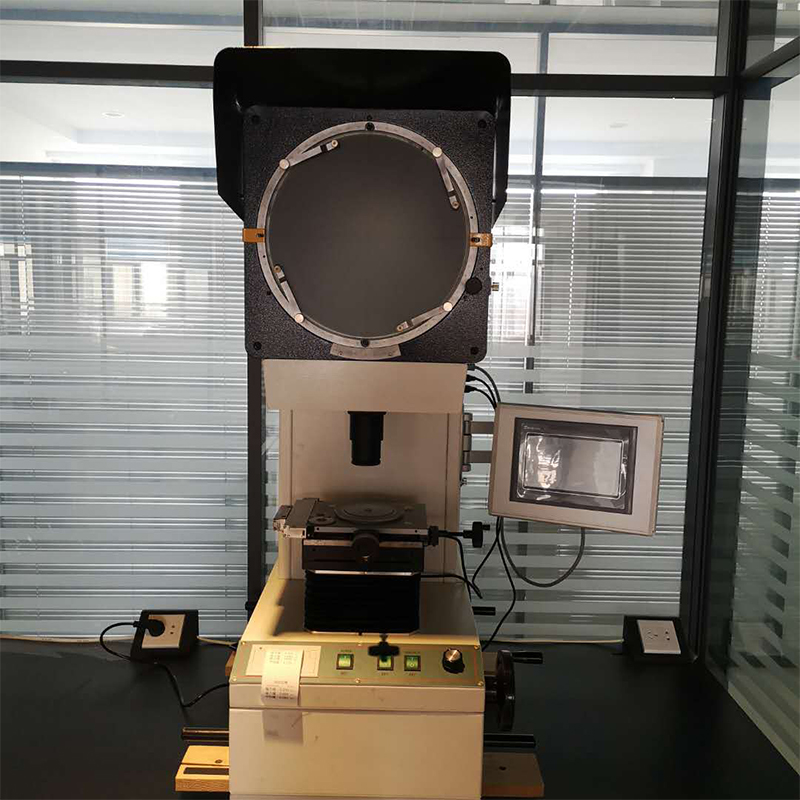

2. Optical Measurement Devices Cameras and optical sensors can capture images of cables as they are produced. Advanced image processing algorithms can analyze these images to determine whether the cables meet specifications. This method is particularly useful for inspecting surface defects and ensuring uniformity throughout the production run.

3. Calipers and Micrometers While more traditional, precise hand-held tools such as calipers and micrometers are still widely used for detailed measurements. These tools require skilled operators but can provide an additional layer of quality assurance in any manufacturing process.

4. Thickness Gauges Thickness gauges are essential when it comes to measuring insulation on cables. Variations in insulation thickness can affect the cable's performance and safety, so accurate gauges are necessary to maintain quality control during production.

measure machine for cables companies

5. Electrical Testing Equipment Measuring machines that assess the electrical properties of cables are crucial for ensuring performance standards. These devices often test parameters such as resistance, capacitance, and insulation integrity. Non-destructive testing methods, like dielectric testing, can also assess the quality of the insulation without damaging the cable.

Integrating Measuring Machines into Production Lines

The integration of measuring machines into the production process can be complex but rewarding. Automation is a significant trend in modern manufacturing, and automated measurement solutions contribute to both speed and accuracy. By employing Industry 4.0 principles, cable companies can connect measuring machines to digital systems that monitor production in real time, allowing for instant adjustments and data analysis.

This digital transformation leads to enhanced traceability, where each component's measurements can be recorded, analyzed, and reported. Such data can be invaluable for identifying trends, streamlining processes, and ultimately reducing waste. Predictive maintenance can also be utilized; if a measuring machine shows discrepancies in standard measurements, it can signal that maintenance is required before the problem escalates.

Challenges and Considerations

While investing in state-of-the-art measuring machines offers numerous benefits, cable companies must also consider challenges such as cost and the need for skilled operators. Initial capital expenditure for advanced machinery can be substantial, and companies need to conduct a thorough cost-benefit analysis to assess the return on investment. Furthermore, as technology advances, ongoing training for staff will be necessary to ensure that they are proficient in using and maintaining these machines.

Conclusion

Measuring machines are indispensable tools for cable companies that seek to maintain high-quality standards and efficiency. The integration of advanced measurement technologies not only enhances product quality but also allows manufacturers to optimize their production processes. By embracing these innovations, cable companies can position themselves as leaders in a competitive market, delivering reliable and safe products that meet the evolving demands of consumers. In an industry where precision is key, investing in advanced measuring solutions is not just beneficial; it's essential for future success.

-

Unleashing the Potential of Digital Profile Projectors

NewsMay.22,2025

-

Smoke Density Test Machines for Fire Safety Assessment

NewsMay.22,2025

-

Revolutionizing Testing with Electronic Tensile Tester

NewsMay.22,2025

-

Innovations in Resistance Test Equipment

NewsMay.22,2025

-

Exploring High Performance Cable Cross Linking Equipment

NewsMay.22,2025

-

Advancements in Conductor Resistance Test Equipment

NewsMay.22,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy