optical measurement instruments factories

The Role of Optical Measurement Instruments in Factories

In the contemporary manufacturing landscape, precision and efficiency are paramount. Optical measurement instruments, with their advanced technology and accuracy, play a critical role in optimizing production processes across various industries. These instruments utilize light to measure various physical characteristics, offering significant advantages over traditional measurement tools.

One of the primary benefits of optical measurement instruments is their non-contact measurement capability. Unlike conventional methods that may involve physical interaction with the object being measured, optical devices can assess dimensions, shapes, and surface characteristics without touching the item. This is particularly advantageous when dealing with delicate parts or mechanisms—the risk of damage is minimized, ensuring that the integrity of the components is maintained throughout the measurement process.

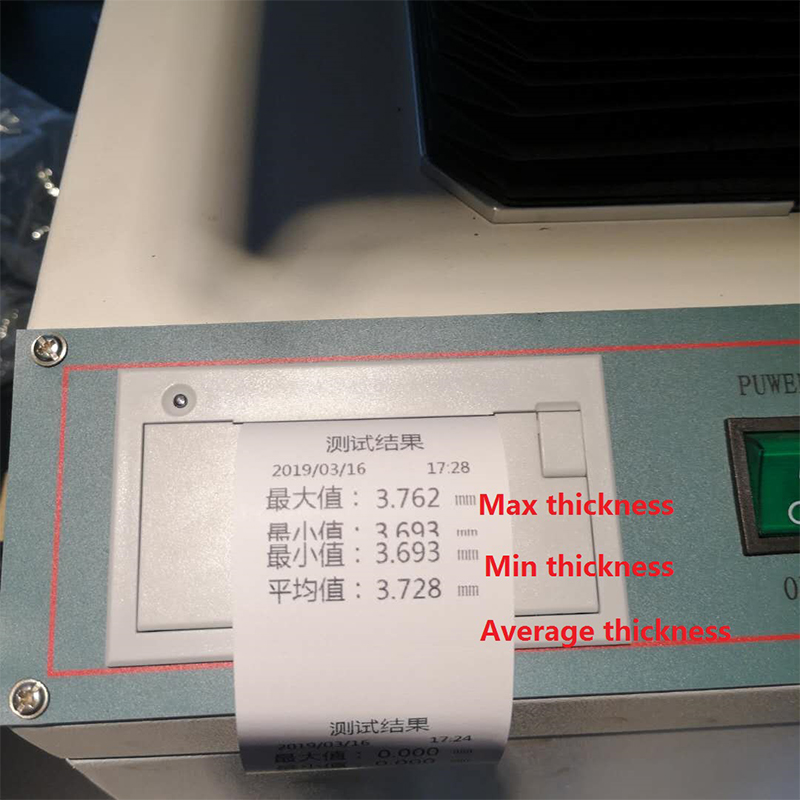

Optical measurement systems, such as laser scanners, vision systems, and Coordinate Measuring Machines (CMMs), employ light to achieve unprecedented accuracies. For instance, laser triangulation enables the precise measurement of distances through the angles formed between the laser beam and the object. Vision systems, on the other hand, utilize high-resolution cameras coupled with sophisticated image processing software to evaluate dimensions and detect any anomalies in the production line. These technological advancements ensure that manufacturers can uphold stringent quality control standards.

optical measurement instruments factories

The implementation of optical measurement instruments also significantly enhances productivity. In fast-paced manufacturing environments, the speed at which measurements can be taken is critical. Optical systems can often deliver real-time results, allowing for immediate adjustments during the manufacturing process. This rapid feedback loop helps in identifying defects or deviations from the specified tolerances early, reducing waste and rework costs. As a result, manufacturers can maintain a competitive edge by increasing output while simultaneously preserving quality.

Moreover, optical measurement technologies are often integrated with industrial automation systems, creating a seamless workflow that enhances operational efficiency. Automated measurement systems can be programmed to perform routine checks automatically, ensuring that each stage of production adheres to quality standards without the need for manual intervention. This not only reduces the likelihood of human error but also frees up skilled personnel to focus on more complex tasks.

The versatility of optical measurement instruments extends across various sectors, including automotive, aerospace, electronics, and medical device manufacturing. In the automotive industry, for example, optical measurements are essential for ensuring that components fit together perfectly, which is crucial for vehicle safety and performance. In the aerospace sector, precision is non-negotiable, and optical instruments are employed to guarantee that parts meet rigorous specifications. Similarly, in electronics, where components can be extremely small and intricate, optical devices provide the necessary resolution to ensure quality and reliability.

In conclusion, optical measurement instruments are indispensable assets in modern factories. Their ability to measure with precision, their non-contact nature, and their integration with automated systems make them essential for maintaining quality and efficiency in production processes. As technology continues to evolve, we can expect even more innovative applications of optical measurement tools, further solidifying their position within the manufacturing ecosystem. Embracing these advanced measurement solutions not only drives productivity but also contributes to the overall success of industries in a rapidly changing global market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy