resistance fixture manufacturer

Resistance Fixture Manufacturers Pioneering Precision in Testing Equipment

In the world of manufacturing and quality control, the importance of accurate measurement cannot be overstated. One of the critical components in this realm is the resistance fixture, an essential tool used for measuring and testing electrical resistance in various materials and components. As industries strive for higher quality standards, the role of resistance fixture manufacturers becomes increasingly vital.

Understanding Resistance Fixtures

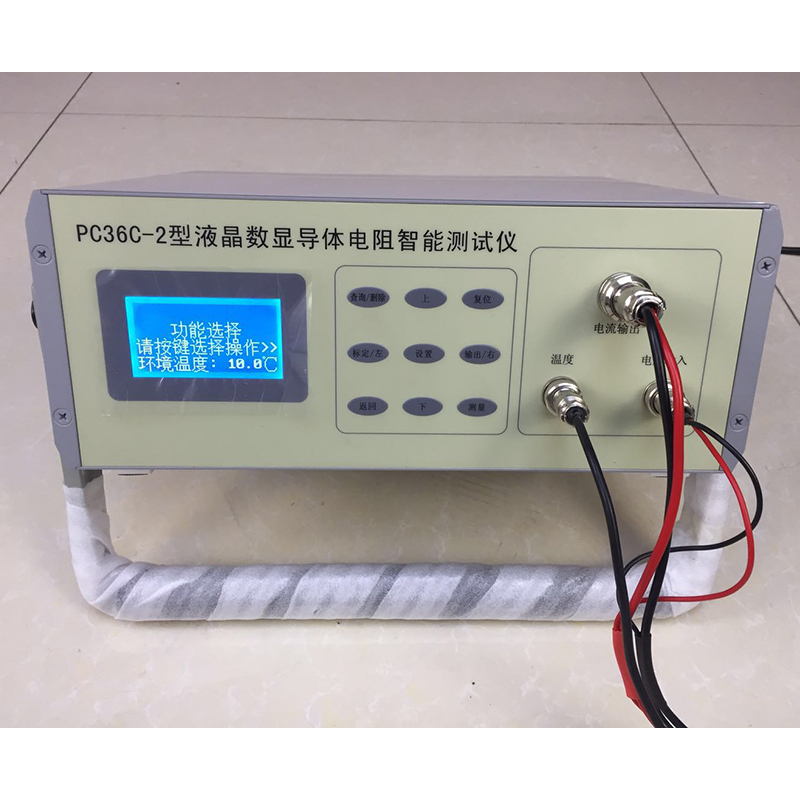

Resistance fixtures are specialized devices designed to accurately assess the resistance of electrical circuits, components, and materials. These fixtures ensure reliable and consistent testing, enabling manufacturers to maintain quality control and compliance with industry standards. They can be tailored to meet specific requirements for different applications, be it in aerospace, automotive, electronics, or telecommunications industries.

A resistance fixture typically consists of several key components electrodes, a housing structure, and connection leads. The electrodes make contact with the material under test, while the housing ensures the stability and alignment of the electrodes. Connection leads facilitate the transfer of electrical current, allowing precise measurement of resistance. The design and construction of these fixtures directly impact the accuracy and reliability of the test results, making the expertise of manufacturers crucial.

The Manufacturing Process

Resistance fixture manufacturers employ a range of advanced techniques and technologies in their production process. High-quality materials are selected to withstand the rigors of testing environments, ensuring durability and reliability. Manufacturers often utilize computer-aided design (CAD) software to create prototypes, refining their designs through testing and feedback.

Precision machining and assembly techniques are employed to ensure that each fixture can meet stringent tolerances. Furthermore, manufacturers often collaborate with industry experts to continuously innovate and enhance their products, keeping pace with advancements in technology and the evolving needs of their customers.

resistance fixture manufacturer

Quality Assurance and Standards

Given the critical nature of the tests performed using resistance fixtures, manufacturers must adhere to strict quality assurance protocols. Many leading manufacturers comply with international standards such as ISO 9001, ensuring that their products meet recognized thresholds for quality and consistency. Rigorous testing and validation processes are integral to their operations, often including calibration, performance testing, and reliability assessments.

Moreover, manufacturers play a pivotal role in helping their customers navigate regulatory requirements specific to their industries. By providing fixtures that meet or exceed these standards, manufacturers support their clients in achieving compliance with safety and quality regulations.

The Future of Resistance Fixture Manufacturing

As technology continues to advance, the future of resistance fixture manufacturing looks promising. The integration of automation and robotics in production processes allows for greater precision and efficiency. Moreover, the rise of smart technologies has birthed the development of intelligent measurement systems that leverage data analytics and artificial intelligence for enhanced testing capabilities.

Manufacturers are also increasingly focusing on sustainability, adopting eco-friendly materials and processes to minimize their environmental impact. This shift not only benefits the planet but also resonates with an expanding base of environmentally conscious consumers and businesses.

Conclusion

Resistance fixture manufacturers stand at the forefront of ensuring that industries can produce reliable and high-quality products. Their dedication to precision, quality assurance, and innovation plays a pivotal role in the manufacturing landscape. By continuously evolving and adapting to the technological advancements and market demands, these manufacturers are not only enhancing their products but also contributing significantly to the overall performance and safety of various industries. As the need for reliable testing solutions continues to grow, the importance of these manufacturers will undoubtedly remain paramount in the years to come.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy