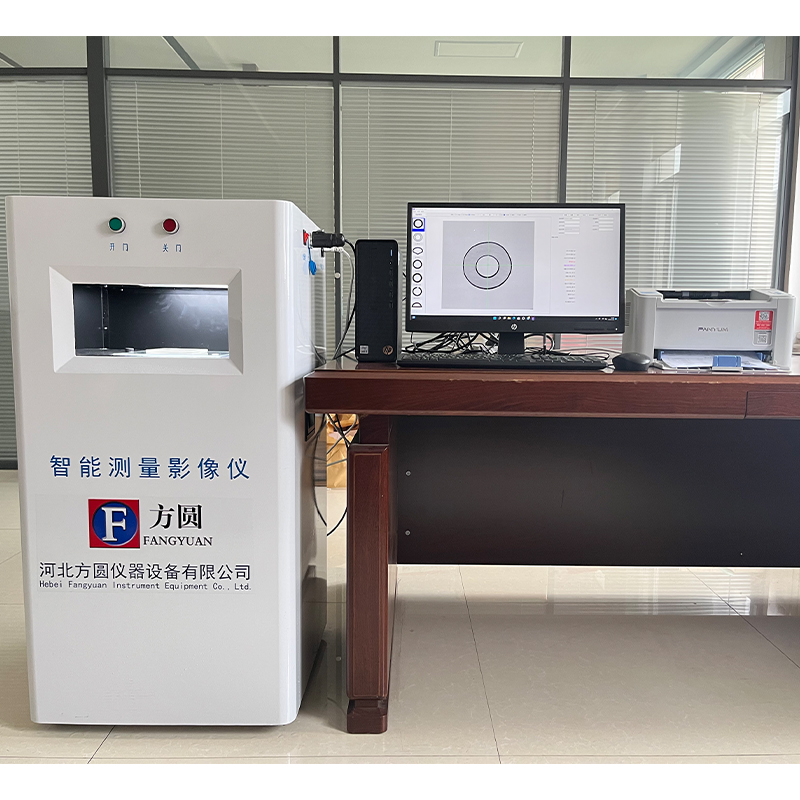

automatic measuring imager factory

The Future of Imaging Developments in Automatic Measuring Imager Factories

In an age where precision and efficiency are paramount, the emergence of automatic measuring imager factories represents a transformative leap in manufacturing technology. These innovative facilities leverage cutting-edge imaging technologies and automation to redefine the standards of measurement in industrial applications.

The Future of Imaging Developments in Automatic Measuring Imager Factories

The core advantage of automatic measuring imager factories lies in their ability to perform measurements quickly and accurately. By employing high-resolution cameras and advanced imaging techniques such as machine vision, these systems can instantly assess various parameters such as size, shape, and surface integrity. For instance, in the automotive industry, an automatic measuring imager can check the dimensions of components like gears or chassis parts, ensuring that they fit perfectly together, thus enhancing overall vehicle quality and safety.

automatic measuring imager factory

Moreover, the automation aspect cannot be understated. With the implementation of robotics and artificial intelligence, these factories can operate 24/7 without the need for human intervention. This relentless functionality not only boosts production rates but also cuts down labor costs, allowing companies to remain competitive in a rapidly evolving market. As industries increasingly prioritize efficiency and precision, the demand for automatic measuring imager technologies will only continue to grow.

Sustainability is another critical factor driving the adoption of automatic measuring imager factories. These systems contribute to waste reduction by identifying defects early in the production process. By doing so, they minimize the need for rework and reduce the amount of scrap material generated. Additionally, with the rise of smart manufacturing and Industry 4.0, these imaging systems can be integrated into larger digital ecosystems, allowing for better resource management and energy efficiency.

The future of automatic measuring imager factories looks promising, with ongoing advancements in technology. Innovations in artificial intelligence will enhance machine learning capabilities, allowing these systems to become more adept at identifying anomalies and predicting potential failures. Furthermore, as the technology matures, we can expect the cost of these solutions to decrease, making them accessible to a wider range of industries, including small and medium enterprises.

In conclusion, automatic measuring imager factories are at the forefront of a new industrial revolution. By providing accurate, efficient, and sustainable measurement solutions, they are not just improving manufacturing processes; they are redefining them. As we continue to embrace technological advancements, these systems will play a crucial role in shaping the future of production, paving the way for greater innovations in quality control and operational efficiency. The potential for growth and development in this sector is immense, and the journey has only just begun.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy