China's Advanced Electronic Tensile Testing Machines for Precision Material Strength Evaluation and Research Development

The Significance of Electronic Tensile Testing Machines in China

In recent years, the manufacturing and material testing industries in China have witnessed substantial growth, driven by rapid industrialization and the demand for high-quality products. One critical piece of equipment in this context is the electronic tensile testing machine, which plays a vital role in evaluating the mechanical properties of materials.

Understanding Electronic Tensile Testing Machines

Electronic tensile testing machines are sophisticated devices designed to measure the tensile strength, elongation, and other mechanical properties of materials such as metals, plastics, rubber, and textiles. These machines operate by applying a controlled tensile force to a specimen until it deforms or breaks. The data obtained from these tests are essential for quality control, product development, and compliance with international standards.

Importance in the Chinese Manufacturing Sector

As China positions itself as a global manufacturing powerhouse, the demand for reliable testing equipment has skyrocketed. Electronic tensile testing machines enable manufacturers to ensure that their products meet stringent quality requirements, thereby enhancing competitiveness in both domestic and international markets. High-performance materials are essential for sectors such as aerospace, automotive, construction, and electronics—industries where material failure can result in catastrophic consequences.

Moreover, these machines provide precise and repeatable results, helping manufacturers to maintain rigorous standards in their production processes. This precision is crucial for innovation, as companies strive to develop new materials that push the boundaries of performance, sustainability, and cost-effectiveness.

Technological Advancements

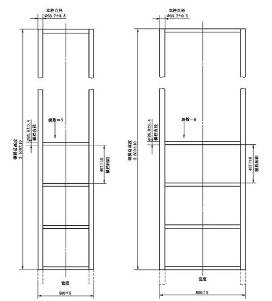

china electronic tensile testing machine

The development of electronic tensile testing machines in China has paralleled advancements in technology. Modern machines are equipped with computer-controlled systems that allow for automated data collection and analysis. With user-friendly interfaces and software that can perform complex calculations, operators can obtain detailed reports on the material properties tested easily. This integration of technology not only increases efficiency but also reduces the likelihood of human error during testing.

Additionally, some of these machines come with advanced features, such as stress-strain curve generation, which helps scientists and engineers visualize the material behavior under load. This data is critical for predicting how materials will perform in real-world applications and for guiding the design process.

Challenges and Future Prospects

Despite the benefits, the industry still faces challenges, including the need for continual training of personnel and the maintenance of advanced machinery to prevent obsolescence. Furthermore, with the increasing focus on sustainability, there is a growing demand for testing equipment that can assess eco-friendly materials.

Looking forward, the future of electronic tensile testing machines in China appears promising. With the shift towards smart manufacturing and the adoption of Industry 4.0 practices, these machines are likely to become part of interconnected systems that provide real-time analysis and feedback, thus guiding production decisions dynamically.

Conclusion

Electronic tensile testing machines are indispensable tools in the landscape of modern manufacturing in China. They not only ensure product quality and compliance with standards but also foster innovation by enabling the development of advanced materials. As technology continues to evolve, the integration of smarter and more efficient testing solutions will further elevate the capabilities of the Chinese manufacturing sector, solidifying its position on the global stage. By investing in and adopting these sophisticated testing machines, China can maintain its trajectory of growth, enhance its manufacturing quality, and support sustainable practices across industries.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy