Manufacturers of Copper and Steel Resistance Testing Equipment for Quality Assurance

Copper and Steel Resistance Tester Factories An Overview

In the modern industrial landscape, the demand for precision measurements has never been greater, particularly in the realms of electrical engineering and materials science. One of the critical tools that serve this need is the resistance tester, specifically designed to assess the conductivity and resistivity of metals like copper and steel. With the rise in technological advancements and production standards, the importance of specialized factories that manufacture these testers has come to the forefront. This article will delve into the significance, technology, and evolution of copper and steel resistance tester factories.

The Importance of Resistance Testing

Resistance testing plays a crucial role in various industries, from construction to electronics. Copper, known for its excellent electrical conductivity, is widely used in wiring, electrical components, and renewable energy systems. Steel, on the other hand, is a fundamental component in construction and manufacturing due to its durability and strength.

Understanding the resistance levels of these materials is essential for ensuring quality, safety, and efficiency. High resistance in electrical connections can lead to energy losses, overheating, and equipment failure. Consequently, reliable resistance testers are essential tools for engineers and technicians who monitor and maintain the integrity of electrical systems and metal structures.

Technological Innovations

The landscape of resistance testing has evolved significantly over the years. Factories producing copper and steel resistance testers are at the forefront of these technological advancements. Modern testers have integrated features that enhance accuracy and usability. For instance, digital resistance testers offer improved precision with the ability to store data, perform auto-calibrations, and connect to computers for detailed analysis.

Moreover, advancements in sensor technology allow testers to measure higher frequencies and low resistance levels accurately. This expanded capability is crucial for industries dealing with high-performance materials where even slight variations in resistance can have substantial effects.

Some factories employ automated production techniques, ensuring consistency and reducing human error. Additionally, factories are increasingly focusing on user-friendly designs, making resistance testers accessible to a broader range of users, from seasoned electricians to technicians in emerging markets.

Key Players in the Industry

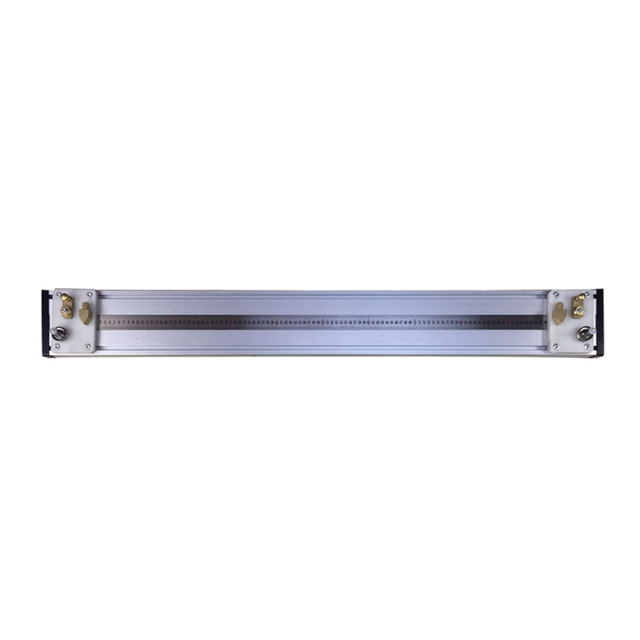

copper and steel resistance tester factories

The global market for copper and steel resistance testers features a mix of established manufacturers and innovative startups. Prominent companies have established themselves as leaders by prioritizing research and development. They continuously refine their products to meet industry standards and customer needs.

These manufacturers often engage in partnerships with research institutions and universities to drive innovation. Such collaborations help in developing novel materials and techniques that improve the performance of resistance testers.

For instance, some companies are exploring the application of nanotechnology to enhance the sensitivity of resistance measurements. This focus on innovation not only keeps these factories competitive but also ensures that they contribute to the broader field of material science.

Environmental Considerations

With the growing emphasis on sustainability, resistance tester factories are also adapting their practices to be more environmentally friendly. Many manufacturers are adopting eco-friendly materials and processes, minimizing waste, and ensuring proper disposal of electronic components.

Moreover, the trend towards renewable energy sources has led to an increased demand for high-performance resistance testers used in solar panel installations and wind turbines. Factories that can deliver products that meet both performance and environmental standards are likely to thrive in the future.

Conclusion

Copper and steel resistance tester factories play an instrumental role in various industries by ensuring the safety, efficiency, and reliability of electrical and structural systems. As technology continues to advance, these factories are evolving in tandem, focusing on innovation, precision, and sustainability. The synergy between technological growth and industrial needs is likely to drive the future of resistance testing, ensuring that these essential tools continue to support modern engineering and manufacturing challenges.

In conclusion, whether you are an electrical engineer seeking to ensure optimal performance in circuits or a technician dedicated to maintaining the structural integrity of buildings and machinery, the evolution of resistance testers from dedicated factories will undoubtedly aid in these vital efforts. With ongoing advancements, the future looks promising for both testers and the factories that produce them.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy