Tailored Optical Coordinate Measurement Solutions for Precision Engineering Applications

Custom Optical Coordinate Measuring Machines Precision Redefined

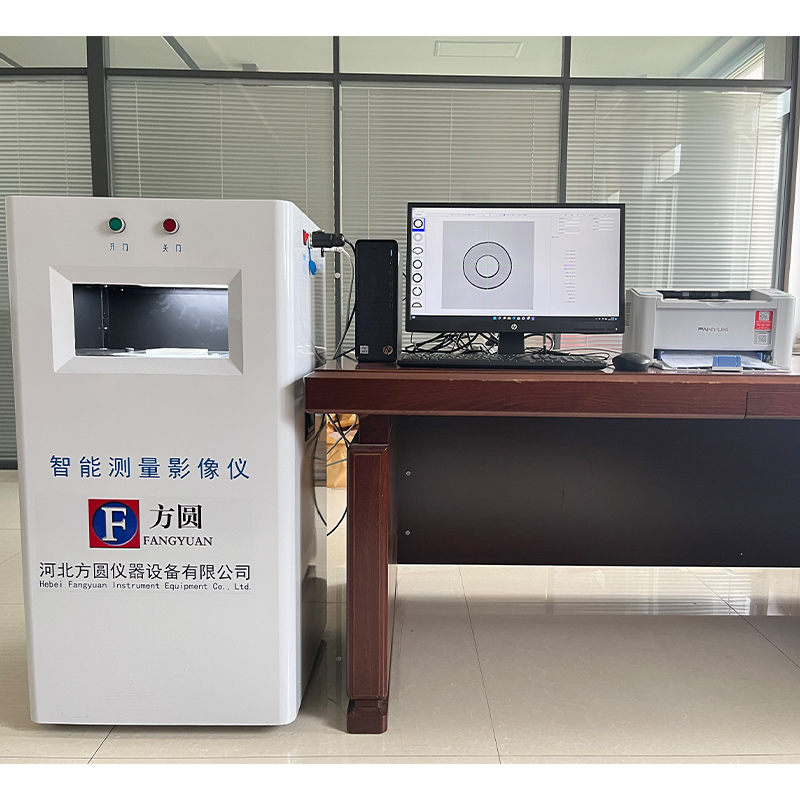

In the world of manufacturing and quality assurance, precision is paramount. Traditionally, coordinate measuring machines (CMMs) have relied heavily on tactile probes to gather dimensional data. However, advancements in technology have given rise to custom optical coordinate measuring machines, which employ non-contact optical systems to achieve unprecedented accuracy and efficiency.

Custom optical CMMs leverage advanced imaging technology, such as lasers and high-resolution cameras, to capture the dimensions of complex parts without physical contact. This non-destructive measurement method is particularly advantageous for delicate components that may be damaged by traditional probing techniques. Industries ranging from aerospace to medical device manufacturing have begun to adopt these machines, recognizing their ability to enhance both the quality and speed of the measurement process.

One of the primary benefits of custom optical CMMs is their versatility. They can be tailored to specific applications, accommodating various shapes, sizes, and material types. For instance, custom setups can include programmable measurement paths, adjustable lighting conditions, and specialized software designed to accommodate specific industry standards. This adaptability allows manufacturers to maintain stringent quality control while simultaneously optimizing their workflow.

custom optical coordinate measuring machine

Moreover, optical coordinate measuring systems provide rapid measurements, significantly reducing downtime and increasing throughput. When coupled with advanced data processing algorithms, these machines can quickly compare measurements against CAD models, allowing for immediate feedback and adjustments during production. This real-time analysis is crucial in environments where precision is vital, enabling manufacturers to catch deviations early and avoid costly mistakes down the line.

The integration of custom optical CMMs in manufacturing processes is not merely a trend; it represents a shift towards embracing innovation and efficiency in quality assurance. As industries increasingly rely on intricate designs and components, the demand for precise measurement solutions will continue to grow. Custom optical CMMs offer a viable solution, empowering manufacturers to meet these demands while ensuring the highest quality of their products.

In conclusion, custom optical coordinate measuring machines exemplify the intersection of accuracy, speed, and adaptability in measurement technology. By enabling non-contact measurement and offering customizable solutions, they provide manufacturers with a powerful tool to enhance quality control processes. As technology continues to advance, the implementation of these systems will likely expand, driving further improvements in the manufacturing landscape. The future of precision measurement is undoubtedly bright, with custom optical CMMs at the forefront of this evolution.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy