ม.ค. . 29, 2025 02:57

Back to list

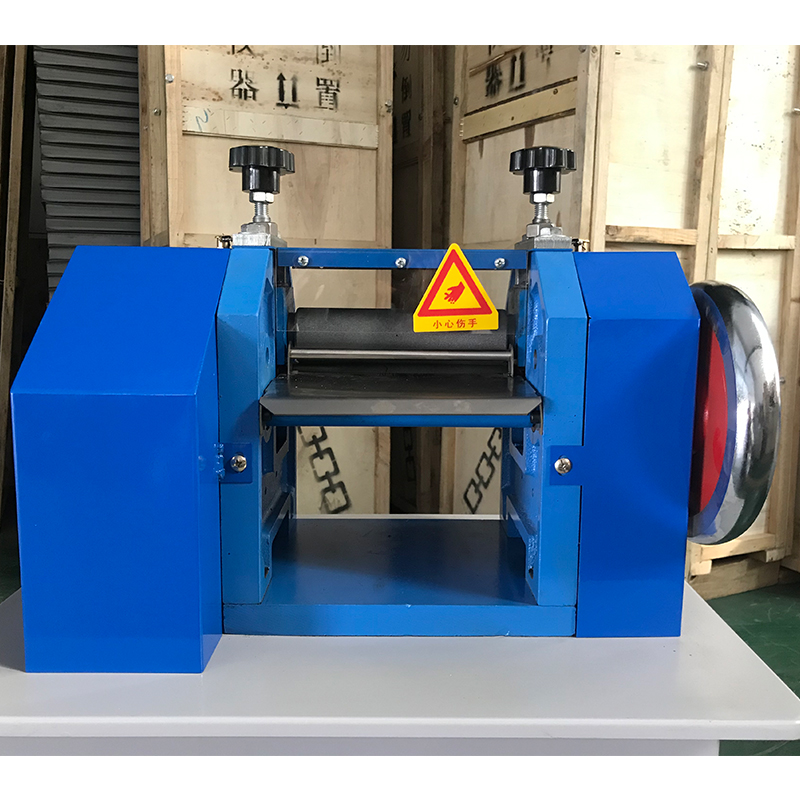

custom tensile force tester

Custom tensile force testers have revolutionized the realm of material testing, offering invaluable insights into the structural integrity of materials across various industries. As businesses aim to innovate and improve, understanding the unparalleled advantages and applications of these testers becomes imperative. With a rich foundation of expertise and credibility, this article delves into the core aspects that make custom tensile force testers an indispensable tool.

Trustworthiness in custom tensile force testers is further bolstered by their robust design and advanced technology integration. These testers often feature state-of-the-art software interfaces that allow for seamless data collection and analysis. By providing real-time feedback and comprehensive reporting capabilities, businesses can make informed decisions swiftly, thus accelerating product development cycles and reducing time to market. Furthermore, the reliability of these testers is evidenced by their longevity and minimal maintenance requirements, assuring stakeholders of consistent performance over time. Experience plays a critical role in the refinement and continuous improvement of custom tensile force testers. Real-world application feedback is essential in the evolution of these instruments. By collaborating closely with industry partners, manufacturers can adapt and innovate, incorporating the latest advancements in sensor technology and automation to enhance the user experience. The iterative design process ensures that custom tensile force testers not only meet but exceed the expectations of their users, delivering unmatched precision and utility. In industries where innovation is the key to staying ahead, the bespoke nature of custom tensile force testers offers a distinct advantage. The ability to design a tester tailored to an organization's specific needs ensures that testing is not only more effective but also more efficient. This customization extends beyond the hardware; it includes software modifications that allow for unique testing protocols and result analyses that are directly relevant to the client's operational objectives. In summary, custom tensile force testers are more than mere instruments; they embody the synthesis of experience, expertise, authority, and trust—all crucial pillars that support their indispensability in material testing. By providing precise, reliable, and tailored solutions, they empower industries to achieve excellence in their products, fortifying the bridge between innovative design and resilient performance. As technology continues to advance, the role of custom tensile force testers will undoubtedly expand, making them quintessential in the quest for material excellence.

Trustworthiness in custom tensile force testers is further bolstered by their robust design and advanced technology integration. These testers often feature state-of-the-art software interfaces that allow for seamless data collection and analysis. By providing real-time feedback and comprehensive reporting capabilities, businesses can make informed decisions swiftly, thus accelerating product development cycles and reducing time to market. Furthermore, the reliability of these testers is evidenced by their longevity and minimal maintenance requirements, assuring stakeholders of consistent performance over time. Experience plays a critical role in the refinement and continuous improvement of custom tensile force testers. Real-world application feedback is essential in the evolution of these instruments. By collaborating closely with industry partners, manufacturers can adapt and innovate, incorporating the latest advancements in sensor technology and automation to enhance the user experience. The iterative design process ensures that custom tensile force testers not only meet but exceed the expectations of their users, delivering unmatched precision and utility. In industries where innovation is the key to staying ahead, the bespoke nature of custom tensile force testers offers a distinct advantage. The ability to design a tester tailored to an organization's specific needs ensures that testing is not only more effective but also more efficient. This customization extends beyond the hardware; it includes software modifications that allow for unique testing protocols and result analyses that are directly relevant to the client's operational objectives. In summary, custom tensile force testers are more than mere instruments; they embody the synthesis of experience, expertise, authority, and trust—all crucial pillars that support their indispensability in material testing. By providing precise, reliable, and tailored solutions, they empower industries to achieve excellence in their products, fortifying the bridge between innovative design and resilient performance. As technology continues to advance, the role of custom tensile force testers will undoubtedly expand, making them quintessential in the quest for material excellence.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy