ม.ค. . 14, 2025 11:11

Back to list

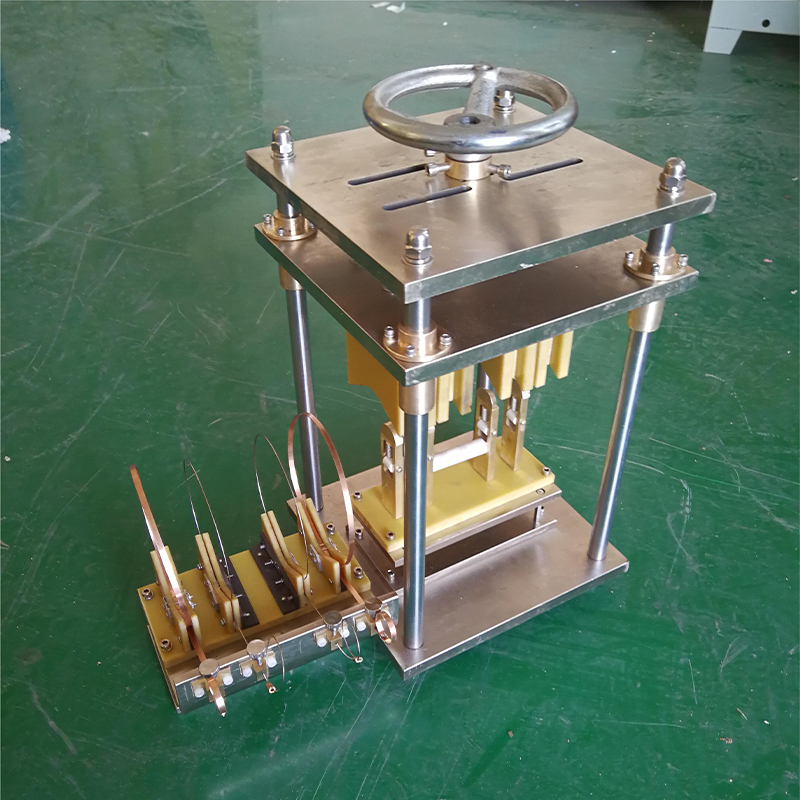

JRT-6 Carbon Fiber Composite Mandrel Winding Test Machine

The modern landscape of material testing is ever-evolving, and among the crucial instruments propelling this advancement is the electronic tensile strength tester. This formidable tool has become indispensable for industries ranging from construction to textiles, where understanding material strength is paramount.

In terms of authoritativeness, the electronic tensile strength tester commands respect across scientific research and practical applications. With rigorous adherence to international testing standards such as ASTM and ISO, these machines ensure that material assessments are comparable and credible across borders. The ability for industries to rely on this standardized evaluation method for determining tensile strength translates directly into better engineered products, whether they be in aerospace, automotive, or consumer goods sectors. Trustworthiness is best embodied by the electronic tensile strength tester's ability to deliver precise data that stakeholders can rely upon. As industries push the boundaries of material capabilities, the demand for reliable data becomes increasingly non-negotiable. The testers’ error margins are minimal, providing certainty and confidence over the lifespan of a product. Furthermore, the incorporation of intelligent software solutions means that data integrity is preserved, with sophisticated analytics offering deeper insight into material behavior under stress. In conclusion, the electronic tensile strength tester is not merely a tool; it is a gateway to innovation and quality assurance. By seamlessly combining modern technology with practical application, it fosters a culture of excellence in material science. For any company or research body striving for venerable status through product durability and safety, investing in such pioneering technology is indispensable. As the field progresses, so does the capacity of these testers, continuously setting new benchmarks in testing accuracy and efficiency.

In terms of authoritativeness, the electronic tensile strength tester commands respect across scientific research and practical applications. With rigorous adherence to international testing standards such as ASTM and ISO, these machines ensure that material assessments are comparable and credible across borders. The ability for industries to rely on this standardized evaluation method for determining tensile strength translates directly into better engineered products, whether they be in aerospace, automotive, or consumer goods sectors. Trustworthiness is best embodied by the electronic tensile strength tester's ability to deliver precise data that stakeholders can rely upon. As industries push the boundaries of material capabilities, the demand for reliable data becomes increasingly non-negotiable. The testers’ error margins are minimal, providing certainty and confidence over the lifespan of a product. Furthermore, the incorporation of intelligent software solutions means that data integrity is preserved, with sophisticated analytics offering deeper insight into material behavior under stress. In conclusion, the electronic tensile strength tester is not merely a tool; it is a gateway to innovation and quality assurance. By seamlessly combining modern technology with practical application, it fosters a culture of excellence in material science. For any company or research body striving for venerable status through product durability and safety, investing in such pioneering technology is indispensable. As the field progresses, so does the capacity of these testers, continuously setting new benchmarks in testing accuracy and efficiency.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

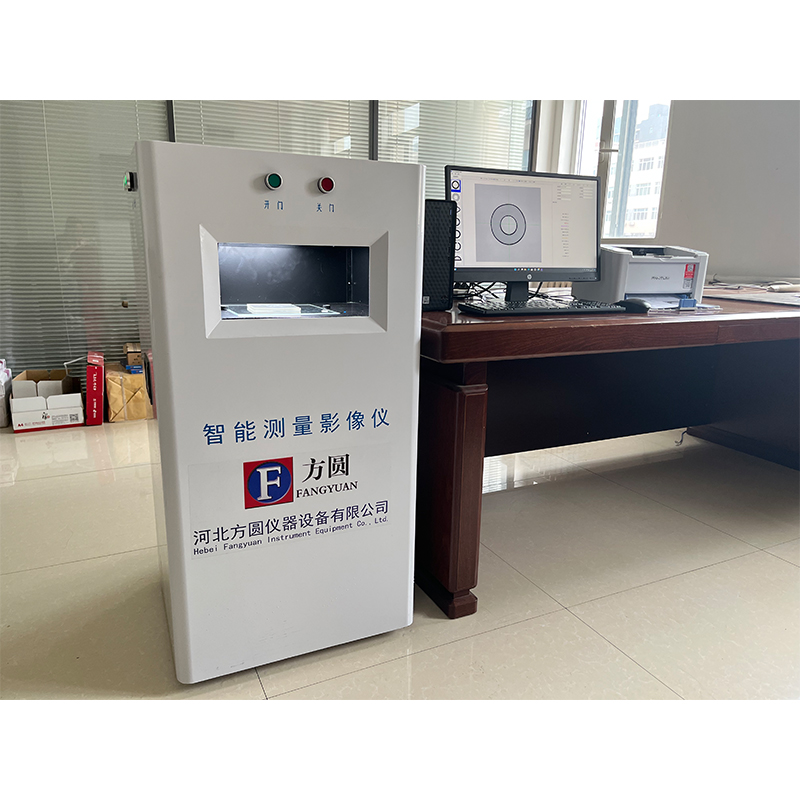

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy