Testing the Shielding Resistance of Semi-Conductive Materials for Enhanced Electrical Performance and Safety

Understanding Semi-Conductive Shielding Resistance Testing A Comprehensive Guide

In the realm of electrical engineering and telecommunications, the importance of shielding cannot be overstated. Shielding serves as a barrier to electromagnetic interference (EMI), ensuring signal integrity and reducing noise in various applications. One crucial aspect of effective shielding is its resistance to electrical conductivity, which is assessed through semi-conductive shielding resistance tests. This article will explore the significance of this testing and the requirements set by manufacturers in the industry.

What is Semi-Conductive Shielding?

Semi-conductive shielding refers to materials that possess moderate electrical conductivity, striking a balance between conducting and insulating properties. This characteristic is particularly vital in cables and wires, where shielding is necessary to protect inner conductors from external electromagnetic fields while minimizing signal loss. The design and material selection for semi-conductive shields are critical to achieving optimal performance in various applications, including data transmission, power distribution, and telecommunications.

The Importance of Shielding Resistance Testing

Conducting semi-conductive shielding resistance tests is essential for several reasons

1. Ensuring Compliance with Standards Many industries adhere to specific standards that dictate the permissible levels of electrical resistance in shielding materials. By performing these tests, manufacturers can ensure their products comply with these standards, avoiding legal and financial repercussions.

2. Maintaining Signal Integrity Effective shielding minimizes electromagnetic interference, which can significantly degrade signal quality. By testing the resistance of the semi-conductive shield, manufacturers can ensure that it will perform reliably in real-world applications, thus maintaining signal integrity.

3. Enhancing Product Reliability Regular testing allows manufacturers to identify potential weaknesses in their shielding materials, enabling them to improve the design or material composition. This proactive approach can lead to more reliable products that meet consumer expectations.

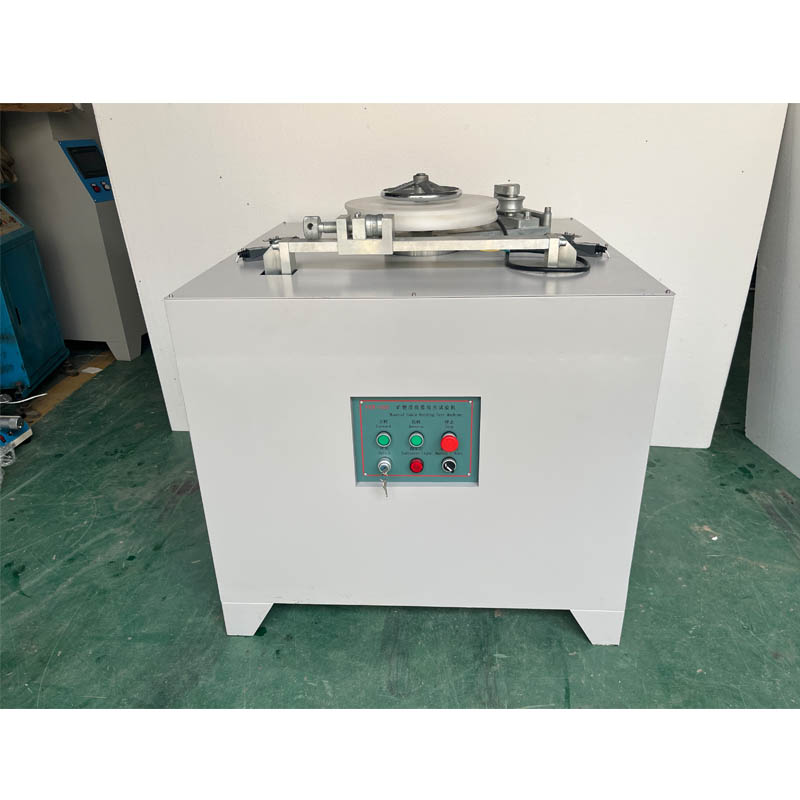

semi-conductive shielding resistance test manufacturer

4. Cost-effectiveness By understanding the resistance characteristics of their shielding materials, manufacturers can optimize their production processes and reduce costs associated with product failures in the field.

The Testing Process

The semi-conductive shielding resistance test involves several steps

1. Sample Preparation Test samples are collected from the manufactured shielding materials. These samples should be representative of the final product to ensure the validity of the results.

2. Resistance Measurement Using specialized equipment, the electrical resistance of the semi-conductive shield is measured. Often, a four-point probe method is employed to minimize the influence of contact resistance and other external factors.

3. Analysis and Reporting The resistance values obtained are analyzed against industry benchmarks and manufacturer's specifications. Detailed reports are generated, highlighting compliance levels and any deviations from expected performance.

4. Quality Control The results of the tests are used to inform quality control processes. If a sample fails to meet the required standards, corrective actions can be taken to adjust the manufacturing process or materials used.

Conclusion

In conclusion, semi-conductive shielding resistance tests are a pivotal aspect of ensuring the effectiveness and reliability of shielding materials in electrical and telecommunication applications. By adhering to rigorous testing protocols, manufacturers can deliver high-quality products that meet industry standards while maintaining signal integrity and reducing the risk of electromagnetic interference. As technology continues to evolve and the demand for efficient, reliable communication grows, the importance of these tests will only increase, cementing their role in the future of electrical engineering.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy