cable thermal elongation test exporters

Cable Thermal Elongation Test Importance and Exporters Overview

The cable thermal elongation test is a critical procedure in the manufacturing and quality assurance of various types of electrical cables. As the demand for reliable and efficient electrical cables continues to grow globally, the significance of thermal elongation testing has become increasingly apparent. This testing process ensures that cables can withstand temperature fluctuations without compromising performance, thereby enhancing safety and durability in various applications.

Understanding Thermal Elongation

Thermal elongation refers to the expansion that occurs in materials when subjected to heat. For cables, this physical property is paramount. Cables are often installed in environments that experience significant temperature changes—be it residential, commercial, or industrial settings. When cables are heated, they need to expand without failure. The thermal elongation test measures the extent to which a cable will elongate when exposed to high temperatures, which is vital for determining its operational lifespan and reliability.

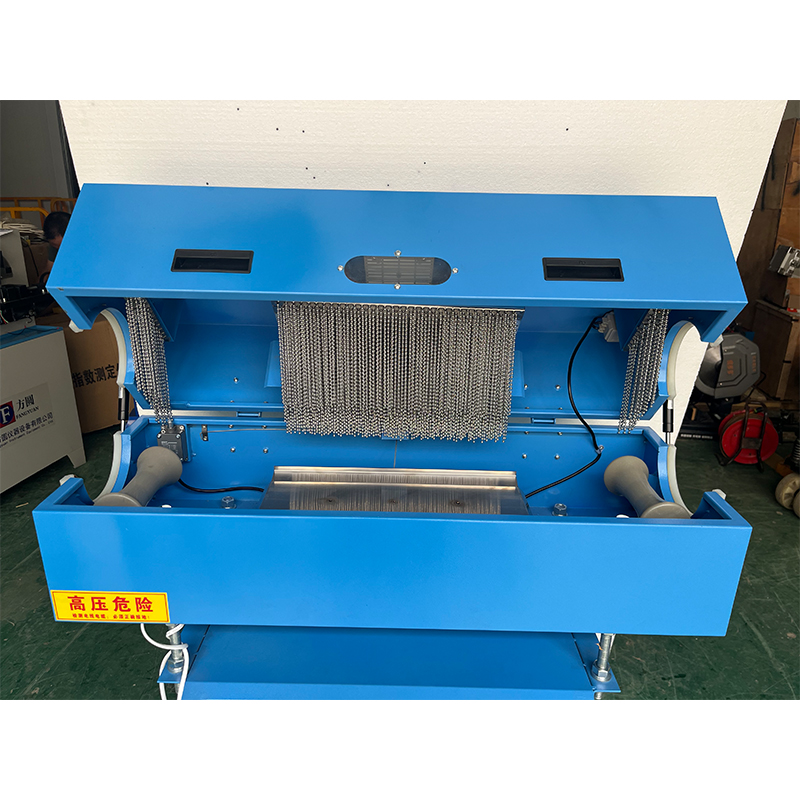

The testing process typically involves subjecting a sample of the cable to controlled heat while measuring its elongation. The results help manufacturers assess whether the cable can withstand thermal stresses without any detrimental effects, such as breaking or developing defects.

Importance of the Test

The implications of thermal elongation tests are profound. For manufacturers, producing cables that can endure extreme temperatures not only boosts product quality but also reduces the risk of failures that can lead to safety hazards, equipment malfunctions, and costly repairs. Furthermore, many regulatory standards require that cables meet specific thermal performance criteria before they can be sold in various markets.

For consumers, using cables that have undergone rigorous thermal elongation testing translates into peace of mind

. It ensures that the products they use will maintain performance, safety, and longevity, which is especially critical in sectors like construction, aerospace, and automotive industries, where electrical systems are paramount.cable thermal elongation test exporters

Exporters of Thermal Elongation Testing Services and Equipment

As the global market for electrical cables expands, so too does the demand for thermal elongation testing services and equipment. A variety of companies specialize in providing these testing services or manufacturing the necessary equipment. Among the leading exporters are companies that focus on quality control and compliance testing, ensuring that cables meet both domestic and international standards.

1. Laboratory Testing Services Several laboratories are equipped to perform thermal elongation tests as part of their comprehensive material testing services. These labs often cater to manufacturers seeking third-party validation of their products. Their expertise in thermal testing provides manufacturers with reliable data to support product claims.

2. Equipment Manufacturers Companies producing specialized thermal testing equipment are also significant players in the export market. They design and manufacture sophisticated machines capable of precisely measuring elongation under controlled heating conditions. These manufacturers often have a global reach, supplying equipment to testing labs and manufacturers across various continents.

3. Certification Bodies Some organizations provide certification services that include thermal elongation testing as part of their product verification processes. By offering these assessments, they help manufacturers achieve compliance with regulatory standards, thus facilitating entry into new markets.

Conclusion

In conclusion, the cable thermal elongation test plays a crucial role in ensuring the reliability and safety of electrical cables. It influences product quality, regulatory compliance, and consumer safety. As global demands for superior cable performance rises, exporters of thermal elongation testing services and equipment are positioned at the forefront of this thriving industry. Their contributions not only help manufacturers boost their product quality but also enhance overall industry standards, ultimately benefiting end-users worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy