Exporter of Resistance Test Machines for Quality Assurance and Performance Evaluation

Understanding Resistance Test Machines A Key Player in Quality Control

In today’s manufacturing and product development landscape, ensuring the reliability and performance of materials is of utmost importance. One essential tool that assists manufacturers in achieving this goal is the resistance test machine. This specialized equipment plays a critical role in quality control by measuring the resistance of materials to various conditions, including electrical, mechanical, and thermal stresses.

What is a Resistance Test Machine?

A resistance test machine is designed to evaluate the physical properties of materials or components by applying defined stress factors and measuring their responses. The resistance tests can vary based on the nature of the material and the specific criteria set forth by industry standards. This equipment is widely used in industries such as electronics, automotive, aerospace, and construction, where material integrity is crucial.

Types of Resistance Tests

There are several types of resistance tests that can be conducted using a resistance test machine

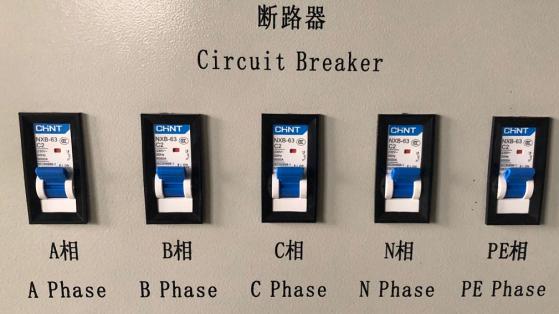

1. Electrical Resistance Testing This involves assessing a material's conductivity by measuring how well it allows electric current to pass through. It is particularly important for electronic components, where even slight variations in resistance can affect overall performance.

2. Mechanical Resistance Testing This evaluates how materials withstand mechanical stresses, such as tension or compression. By measuring parameters such as tensile strength and yield strength, manufacturers can ensure that the materials used in their products can endure the forces they will encounter in real-world applications.

3. Thermal Resistance Testing This examines how materials respond to extreme temperatures. By subjecting materials to high or low temperatures, manufacturers can assess how well they will perform in adverse conditions.

Importance of Resistance Test Machines in Quality Control

Quality control is a critical aspect of manufacturing, as it directly impacts product reliability and customer satisfaction. Resistance test machines contribute to maintaining high-quality standards in several ways

- Compliance with Industry Standards Many industries have strict regulations concerning material performance. Resistance test machines help manufacturers comply with these standards, ensuring that their products are safe and reliable.

- Reducing Failures and Defects By identifying potential weaknesses in materials before they are used in production, resistance test machines help reduce the likelihood of product failures. This proactive approach can save manufacturers significant time and resources in corrective actions and product recalls.

resistance test machine exporter

- Enhancing Product Development By understanding the resistance characteristics of materials, engineers can make informed decisions during the design phase

. This knowledge enables the development of more durable and efficient products.The Role of Exporters in the Resistance Test Machine Market

The demand for resistance test machines has grown globally, leading to the emergence of numerous exporters in this field. These exporters play a pivotal role in the supply chain, providing manufacturers with access to state-of-the-art testing equipment tailored to their specific needs.

Exporters often specialize in providing customized solutions, ensuring that the resistance test machines they supply meet the unique requirements of different industries. This specialization can include offering advanced technology, software integration, and support services that enhance the testing process.

Choosing the Right Resistance Test Machine

When selecting a resistance test machine, manufacturers should consider several factors

- Testing Capabilities Ensure that the machine can perform the specific resistance tests required for your materials.

- Accuracy and Precision Look for machines that offer high levels of accuracy to ensure reliable results.

- Ease of Use and Maintenance A user-friendly interface and low maintenance requirements can significantly impact efficiency and operational downtime.

- Technical Support Reliable support from the manufacturer or exporter can be invaluable, especially when integrating new equipment into existing processes.

Conclusion

In conclusion, resistance test machines are vital tools in ensuring the quality and reliability of materials across various industries. By investing in advanced testing equipment and leveraging the expertise of exporters, manufacturers can enhance their quality control processes, reduce product failures, and ultimately deliver superior products to their customers. As technology continues to evolve, the importance of resistance testing will only increase, making it an essential consideration for any organization focused on excellence in product development and manufacturing.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy