Jan . 14, 2025 11:14

Back to list

Wire and Cable Smoke Density Test Machine

The evolution of the electronic universal tensile testing machine has redefined the parameters of precision and reliability in material testing. As industries increasingly demand high-quality products, these testing machines have emerged as quintessential instruments, ensuring that materials can withstand everyday stresses and perform consistently.

Trustworthiness is further enhanced by the consistent calibration of these machines. Regular calibration and maintenance, conducted by certified technicians, ensure that measurements remain accurate and dependable over time. This attention to detail affirms the machine's reliability, providing users with consistent peace of mind that their material assessments are flawless. Furthermore, the investment in an electronic universal tensile testing machine is justified by its robust design and longevity. Constructed with high-quality materials, these machines endure rigorous use without compromising accuracy. The minimal downtime ensures that testing processes continue uninterrupted, a critical factor for businesses with demanding schedules. User testimonials often echo the sentiment of increased productivity and efficiency after integrating these machines into their quality assurance processes. Reducing the time needed for testing without sacrificing accuracy translates into faster production timelines, enhancing a company's competitive edge. In conclusion, the electronic universal tensile testing machine stands as a pillar of precision in the material testing domain. Its ability to deliver detailed, reliable, and standardized data makes it an invaluable asset for engineers and manufacturers striving to ensure that their products not only meet but often exceed market expectations. As a testament to its capabilities, this machine remains an indispensable tool in ensuring the strength and resilience of materials used in everyday applications, continually upholding the industry's confidence in product excellence.

Trustworthiness is further enhanced by the consistent calibration of these machines. Regular calibration and maintenance, conducted by certified technicians, ensure that measurements remain accurate and dependable over time. This attention to detail affirms the machine's reliability, providing users with consistent peace of mind that their material assessments are flawless. Furthermore, the investment in an electronic universal tensile testing machine is justified by its robust design and longevity. Constructed with high-quality materials, these machines endure rigorous use without compromising accuracy. The minimal downtime ensures that testing processes continue uninterrupted, a critical factor for businesses with demanding schedules. User testimonials often echo the sentiment of increased productivity and efficiency after integrating these machines into their quality assurance processes. Reducing the time needed for testing without sacrificing accuracy translates into faster production timelines, enhancing a company's competitive edge. In conclusion, the electronic universal tensile testing machine stands as a pillar of precision in the material testing domain. Its ability to deliver detailed, reliable, and standardized data makes it an invaluable asset for engineers and manufacturers striving to ensure that their products not only meet but often exceed market expectations. As a testament to its capabilities, this machine remains an indispensable tool in ensuring the strength and resilience of materials used in everyday applications, continually upholding the industry's confidence in product excellence.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

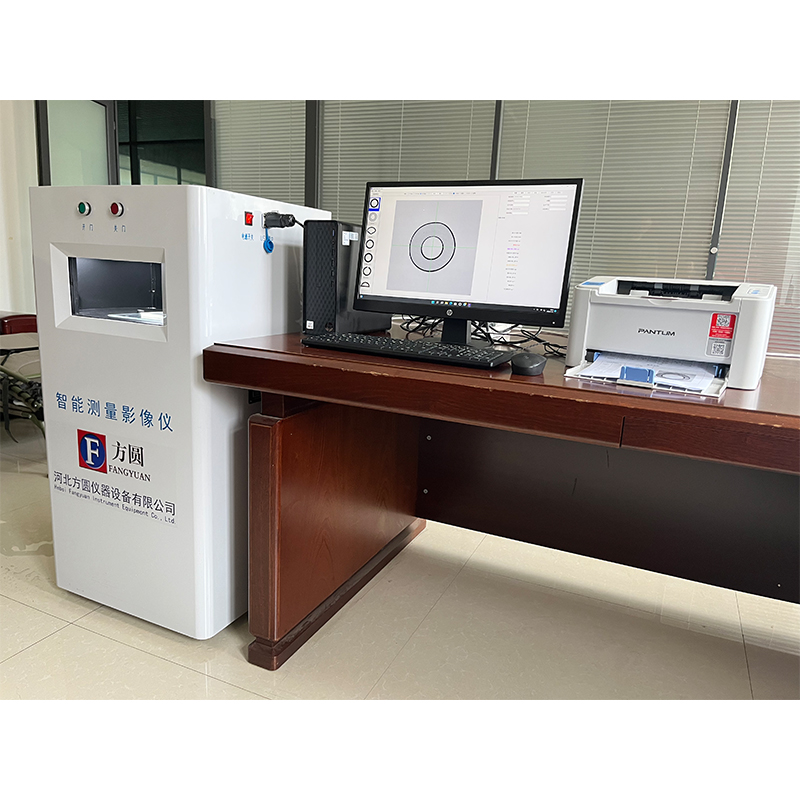

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy