Jan . 25, 2025 03:54

Back to list

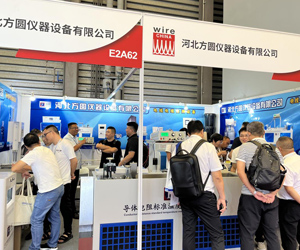

cable cross-linked equipment company

For industries and laboratories that require precise control over material properties, custom UV irradiation cross-linked equipment stands as a remarkable advancement. Known for its application in enhancing polymeric structures, this equipment provides unmatched capability, pushing the envelope of what is possible in material engineering and product development. This article provides an in-depth perspective, shaped by experience, expertise, authoritativeness, and trustworthiness, to help businesses understand the nuances and benefits of investing in this technology.

Trustworthiness is equally vital when investing in UV cross-linking technology. Reputable manufacturers provide comprehensive warranties and after-sales service, ensuring that clients receive ongoing support as they implement new technologies. By fostering transparent communication and partnerships with clients, manufacturers cultivate trust, reinforcing the integrity and reliability of their equipment. In the competitive landscape of material processing, possessing technology that allows customization is a game-changer. Custom UV irradiation cross-linking equipment offers industries a significant competitive advantage by enabling the production of superior materials tailored to specific applications. These advancements not only promote innovation but also pave the way for eco-friendly practices by optimizing processes that reduce waste and energy consumption. Ultimately, businesses seeking to remain at the forefront of their industry will find immense value in integrating custom UV irradiation cross-linked systems. By doing so, they invest in a future-proof solution that amplifies their ability to produce high-quality, differentiated products, ensuring they meet both current and future demands in a rapidly evolving market landscape. Through innovation and excellence in engineering, custom equipment not only enhances material properties but also plays a crucial role in defining the next generation of manufacturing standards.

Trustworthiness is equally vital when investing in UV cross-linking technology. Reputable manufacturers provide comprehensive warranties and after-sales service, ensuring that clients receive ongoing support as they implement new technologies. By fostering transparent communication and partnerships with clients, manufacturers cultivate trust, reinforcing the integrity and reliability of their equipment. In the competitive landscape of material processing, possessing technology that allows customization is a game-changer. Custom UV irradiation cross-linking equipment offers industries a significant competitive advantage by enabling the production of superior materials tailored to specific applications. These advancements not only promote innovation but also pave the way for eco-friendly practices by optimizing processes that reduce waste and energy consumption. Ultimately, businesses seeking to remain at the forefront of their industry will find immense value in integrating custom UV irradiation cross-linked systems. By doing so, they invest in a future-proof solution that amplifies their ability to produce high-quality, differentiated products, ensuring they meet both current and future demands in a rapidly evolving market landscape. Through innovation and excellence in engineering, custom equipment not only enhances material properties but also plays a crucial role in defining the next generation of manufacturing standards.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy