Şub . 19, 2025 06:16

Back to list

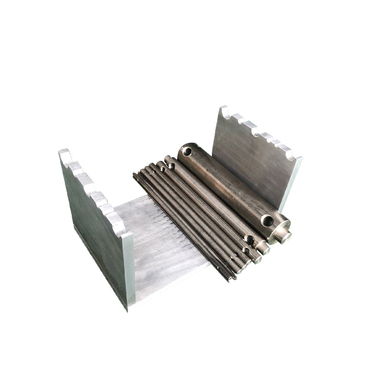

cable smoke density test machine company

The modern manufacturing landscape thrives on innovation and precision, and cable bending test machine factories are at the forefront of this evolution. These specialized facilities play a pivotal role in ensuring the reliability and durability of cables used across various industries. Drawing from extensive industry experience, in-depth expertise, and authoritative insights, this article explores the intricacies of cable bending test machine factories and how they maintain their high trustworthiness in a competitive market.

Trustworthiness is perhaps the most critical aspect for cable bending test machine factories, as clients rely heavily on the reliability of the machines for their own quality assurance processes. Trust is built over years of consistent delivery, supported by comprehensive customer service and after-sales support. Many factories offer extensive training programs for client technicians, ensuring that the machines are used correctly and maintained for longevity. This commitment to customer satisfaction and support enhances the factory's reputation and builds long-term relationships with clients. Another aspect contributing to trust is transparency; reputable factories often provide detailed documentation, including user manuals, performance metrics, and maintenance guidelines. This transparency extends to the factory operations, where potential clients or industry inspectors might be given tours to witness firsthand the production and testing processes. An open-door policy signifies confidence in their capabilities and an eagerness to engage with the wider industry community. Globalization has also influenced cable bending test machine factories, encouraging them to adopt international best practices and incorporate feedback from global clients. This adaptability has allowed many facilities to position themselves as leaders in innovation, producing machines that cater to the ever-evolving requirements of industries like telecommunications, automotive, and aerospace. In conclusion, cable bending test machine factories epitomize the intersection of experience, expertise, authoritativeness, and trustworthiness. Their dedication to high standards and continuous improvement ensures that they remain integral to the manufacturing sector, providing tools that are essential for product development and quality assurance. As industries advance, these factories continue to innovate, embodying resilience and reliability in every machine they produce.

Trustworthiness is perhaps the most critical aspect for cable bending test machine factories, as clients rely heavily on the reliability of the machines for their own quality assurance processes. Trust is built over years of consistent delivery, supported by comprehensive customer service and after-sales support. Many factories offer extensive training programs for client technicians, ensuring that the machines are used correctly and maintained for longevity. This commitment to customer satisfaction and support enhances the factory's reputation and builds long-term relationships with clients. Another aspect contributing to trust is transparency; reputable factories often provide detailed documentation, including user manuals, performance metrics, and maintenance guidelines. This transparency extends to the factory operations, where potential clients or industry inspectors might be given tours to witness firsthand the production and testing processes. An open-door policy signifies confidence in their capabilities and an eagerness to engage with the wider industry community. Globalization has also influenced cable bending test machine factories, encouraging them to adopt international best practices and incorporate feedback from global clients. This adaptability has allowed many facilities to position themselves as leaders in innovation, producing machines that cater to the ever-evolving requirements of industries like telecommunications, automotive, and aerospace. In conclusion, cable bending test machine factories epitomize the intersection of experience, expertise, authoritativeness, and trustworthiness. Their dedication to high standards and continuous improvement ensures that they remain integral to the manufacturing sector, providing tools that are essential for product development and quality assurance. As industries advance, these factories continue to innovate, embodying resilience and reliability in every machine they produce.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy