Exporters of Conductor Resistance Testing Equipment and Fixtures for Reliable Electrical Measurements

Understanding Conductor Resistance Test Fixtures Exporters' Insights

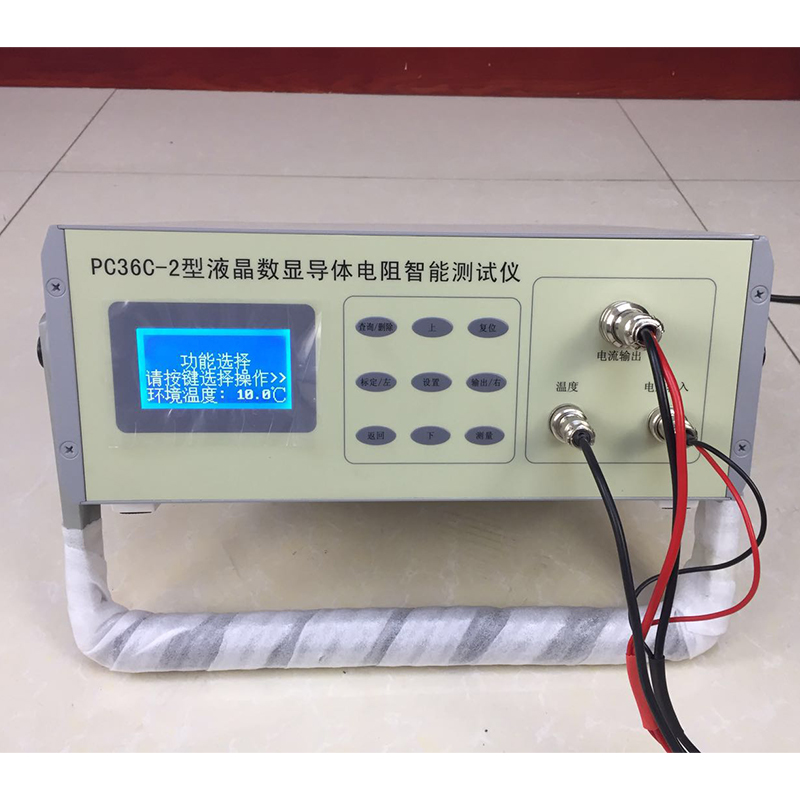

In the modern electrical landscape, ensuring the integrity and reliability of conductors is of paramount importance. This is where conductor resistance test fixtures come into play. These specialized devices are used to measure the resistance of electrical conductors and are crucial for assessing the performance and safety of electrical systems. For exporters in this field, understanding the nuances of conductor resistance test fixtures is essential to meet global demands and standards.

The Role of Conductor Resistance Test Fixtures

Conductor resistance test fixtures are instrumental in determining the electrical resistance of conductive materials. This measurement is vital because excessive resistance can lead to overheating, energy loss, and potential failures within electrical systems. Testing the resistance of conductors, whether they are copper, aluminum, or other alloys, helps manufacturers identify any defects or inconsistencies that could hinder performance.

Exporters dealing in these testing instruments must ensure that their products are capable of providing accurate and reliable measurements. This is achieved through careful design considerations, which include accommodating various conductor sizes and types, as well as integrating advanced measuring technologies.

Key Features to Consider

1. Accuracy and Precision The primary function of a test fixture is to deliver precise measurements. Exporters must prioritize fixtures that utilize high-quality components and calibration processes to ensure reliability.

2. Compatibility Since conductors can vary widely in size and type, fixtures should offer versatility. This includes being adaptable to various shapes and allowing for easy adjustments to accommodate different conductor configurations.

conductor resistance test fixture exporters

3. User-Friendly Design Efficiency in testing is crucial for any manufacturing process. Fixtures that are easy to set up and operate will be highly valued in the market. Features such as intuitive interfaces and ergonomic designs can significantly enhance user interaction.

4. Durability and Portability Given the potential for use in diverse environments, including field testing, a robust and portable design is essential. Exporters should offer fixtures constructed from durable materials that can withstand the rigors of regular use.

5. Compliance with Standards As global standards for electrical testing continue to evolve, adherence to international testing standards is vital. Exporters must ensure that their fixtures not only meet but exceed these requirements to gain a competitive edge in the market.

Market Trends and Export Opportunities

The demand for reliable conductor resistance test fixtures is projected to grow in conjunction with the expansion of electrical infrastructure globally. This growth is particularly evident in emerging markets where investments in energy production and distribution are on the rise. Exporters who are equipped with high-quality, compliant test fixtures can tap into these expanding markets.

Additionally, with the push for renewable energy sources, there is a growing need for reliable testing solutions for new types of conductors used in solar panels and wind turbines. Exporters should consider these emerging trends and tailor their product offerings to meet the unique needs of these industries.

Conclusion

Conductor resistance test fixtures represent a critical component in the electrical testing industry, ensuring the performance and safety of electrical systems worldwide. For exporters, understanding and emphasizing the key features needed in these fixtures will not only enhance their product offerings but also position them favorably in a competitive market. As global demand continues to rise, the ability to deliver high-quality testing solutions will be a defining factor in the success of exporters in this field. By remaining attuned to industry standards and market trends, they can effectively navigate the complexities of international trade and contribute to safer and more efficient electrical systems globally.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy