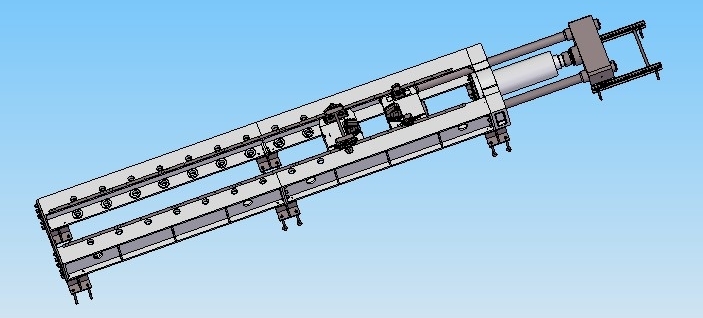

custom power frequency spark test machine

Custom Power Frequency Spark Test Machine Ensuring Electrical Safety and Reliability

In the realm of electrical engineering, ensuring the safety and reliability of electrical equipment is paramount. One of the critical tests used to achieve this is the power frequency spark test, which is conducted using a specialized device known as the power frequency spark test machine. This article delves into the importance, functionality, and features of a custom power frequency spark test machine.

Understanding Power Frequency Spark Testing

Power frequency spark testing, also known as dielectric withstand testing, is a method used to evaluate the insulation integrity of electrical equipment. The test applies a high voltage, typically at the power frequency of 50 Hz or 60 Hz, to the insulation, which allows engineers to identify any weaknesses or breakdowns in the insulation before the equipment is put into service. This process is crucial for preventing electrical failures, which can lead to serious accidents, equipment damage, and costly downtime.

Custom Power Frequency Spark Test Machines

While standard power frequency spark test machines are widely available, many organizations require custom solutions tailored to their specific needs. A custom power frequency spark test machine is designed to meet unique specifications, which may include varying voltage levels, test durations, and specific safety features. By opting for a custom machine, companies can ensure that the testing process aligns perfectly with their equipment characteristics and industry standards.

Key Features of Custom Power Frequency Spark Test Machines

1. Adjustable Voltage Settings One of the primary advantages of a custom spark test machine is the ability to adjust voltage levels according to the specific application. This flexibility allows users to perform tests on a variety of equipment, ensuring comprehensive evaluation processes.

custom power frequency spark test machine

2. Robust Safety Protocols Safety is a significant concern when dealing with high-voltage equipment. Custom machines can be equipped with enhanced safety features, including emergency shut-off systems, fail-safes, and remote operation capabilities. These features help to minimize risks associated with high-voltage testing, protecting both the operator and the equipment.

3. User-Friendly Interface A well-designed user interface is crucial for efficient operation. Custom machines can incorporate intuitive controls, digital displays, and data logging capabilities, making the testing process more manageable and informative. Operators can easily monitor voltage levels, test durations, and the overall status of the testing process.

4. Versatile Testing Capabilities Depending on the industry, the requirements for spark testing can vary vastly. A custom machine may include options for performing additional tests, such as insulation resistance testing or partial discharge measurements. This versatility makes it an invaluable tool for comprehensive equipment analysis.

5. Durability and Reliability Specification of high-quality materials and construction techniques ensures that the custom spark test machine can withstand rigorous testing conditions. A durable design translates to long-term reliability, reducing maintenance costs and ensuring consistent performance over time.

The Importance of Custom Solutions

The demand for tailored solutions stems from the diverse needs of different industries, including power generation, manufacturing, and telecommunications. A one-size-fits-all approach may not effectively address the complexities involved in the testing of specialized equipment. Custom power frequency spark test machines allow businesses to innovate and adapt their processes, enhancing the overall safety and efficiency of their operations.

Conclusion

In conclusion, a custom power frequency spark test machine is an essential tool for ensuring the safety and reliability of electrical equipment. By providing adjustable parameters, robust safety features, and versatile testing capabilities, these machines play a pivotal role in preventing electrical failures and ensuring compliance with industry standards. As technology evolves, the importance of tailored testing solutions will only continue to grow, making custom spark test machines a vital asset in the electrical engineering domain. Investing in such equipment not only enhances safety but also ultimately contributes to the longevity and performance of electrical systems worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy