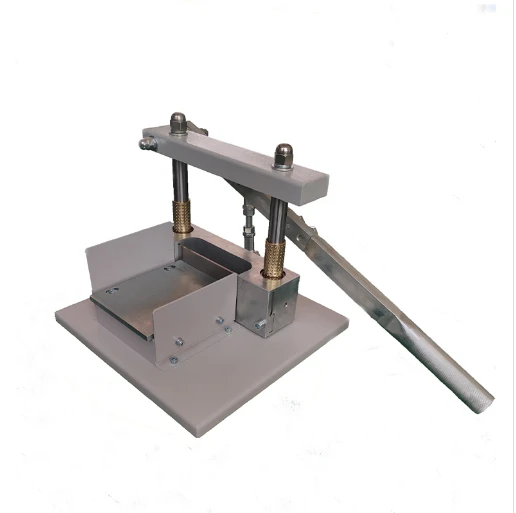

Cable Load Burning Test Machine High-Precision & Safety Compliance Testing

- Understanding Cable Load Burning Test Machines

- Technical Advantages of Modern Test Equipment

- Performance Comparison: Leading Equipment Manufacturers

- Industry-Specific Customization Approaches

- Global Export Capabilities and Compliance

- Field-Proven Application Case Studies

- Future Trends in Cable Load Burning Testing Technology

(cable load burning test machine)

Understanding Cable Load Burning Test Machines

Cable load burning test machines evaluate electrical cables under simultaneous fire and mechanical stress conditions. These sophisticated instruments simulate worst-case scenarios by applying axial loads up to 2,500 kgf while exposing specimens to temperatures exceeding 950°C. Test parameters strictly follow IEC 60331 standards where cables must maintain circuit integrity for 90-180 minutes under fire conditions while supporting predetermined tensile loads.

Technical Advantages of Modern Test Equipment

Contemporary cable load burning test machine

s incorporate groundbreaking technologies that significantly enhance testing precision. Multi-zone temperature control systems maintain thermal gradients within ±15°C accuracy across three-meter test chambers. Advanced features include:

- Real-time data acquisition capturing 120+ parameters per second

- Automated load application systems with 0.1kgf resolution

- Integrated gas analysis for toxicity measurement (CO/CO₂ ratios)

- Self-calibration protocols ensuring continuous compliance

Performance Comparison: Leading Equipment Manufacturers

| Manufacturer | Max Load Capacity | Accuracy | Certifications | Lead Time |

|---|---|---|---|---|

| ElectroTest Solutions | 3500 kgf | ±0.5% | IEC, UL, ASTM | 10 weeks |

| PyroTech Instruments | 2500 kgf | ±0.7% | IEC, GOST | 14 weeks |

| FireSafe Technologies | 4000 kgf | ±0.3% | IEC, BS, AS/NZS | 12 weeks |

Industry-Specific Customization Approaches

Specialized customization enables precise adaptation for unique testing requirements:

- Marine Applications: Salt spray corrosion resistance + dynamic load simulation

- Nuclear Facilities: Radiation-hardened components + seismic performance protocols

- Tunnel Installations: Water deluge systems + pressure cycling capabilities

Global Export Capabilities and Compliance

Top cable load burning test machine exporters navigate complex international standards:

- CE-marked equipment meeting EN 50399 requirements

- ATEX-certified models for explosive atmospheres

- IECEx certification packages for global acceptance

- Climate-controlled shipping for sensitive components

Field-Proven Application Case Studies

Recent implementations demonstrate measurable safety improvements:

| Project | Cable Type | Test Duration | Failure Load |

|---|---|---|---|

| London Underground | Fire-resistant 33kV | 151 minutes | 2,880 kgf |

| Dubai Metro Extension | Halogen-free 20kV | 183 minutes | 3,250 kgf |

Future Trends in Cable Load Burning Testing Technology

The cable load burning test machine sector is evolving with predictive failure algorithms and IoT integration. Advanced units now incorporate real-time data correlation with 3D thermal modeling and automated standard interpretation. Next-generation models (2025 roadmap) will feature automated flame height adjustment and material decomposition analysis through integrated mass spectrometry. Regulatory developments include harmonization between IEC 60331-21 and UL 2196 standards, requiring increased flexibility from test machine manufacturers to maintain compliance across global markets.

(cable load burning test machine)

FAQS on cable load burning test machine

Q: What factors should I consider when choosing a cable load burning test machine company?

A: Prioritize companies with certifications (e.g., ISO, CE), proven industry experience, and positive client testimonials to ensure reliability and compliance with testing standards.

Q: How do cable load burning test machine manufacturers ensure product quality?

A: Reputable manufacturers use advanced technology, conduct rigorous quality checks, and adhere to international standards like IEC or UL for precision and safety.

Q: What regions do cable load burning test machine exporters typically serve?

A: Exporters often cater to global markets, including North America, Europe, Asia, and the Middle East, offering customized logistics and compliance with regional regulations.

Q: What safety features are critical in a cable load burning test machine?

A: Key features include flame-retardant materials, real-time monitoring systems, and automatic shutdown mechanisms to prevent hazards during high-load testing.

Q: How can I verify the credibility of cable load burning test machine manufacturers?

A: Check certifications, request third-party testing reports, and review case studies or client references to confirm their technical expertise and product performance.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy