china tensile tester shear strength

Understanding Shear Strength Testing with a China Tensile Tester

In engineering and materials science, shear strength is a critical property that determines how materials will perform under various loading conditions. The ability to accurately measure this property is essential for ensuring the safety and reliability of products. A popular tool for measuring shear strength is the tensile tester, which is widely used in laboratories and industries around the world, including in China.

What is Shear Strength?

Shear strength is the ability of a material to resist sliding forces applied parallel to its surface. It is crucial for components that experience forces from different directions, such as bolts, rivets, and structural elements. When a shear force is applied, the material can fail in different modes, including ductile failure (where the material deforms significantly before failure) or brittle failure (where the material fractures suddenly).

The Role of Tensile Testers

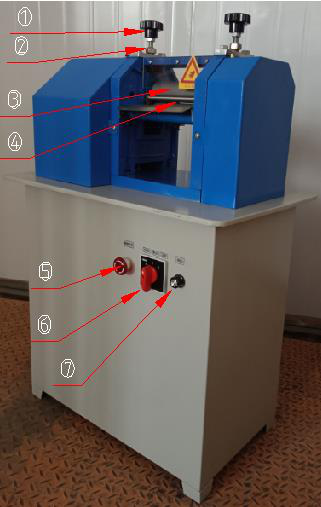

Tensile testers are designed to apply tension to a sample and measure its response until failure. While they are primarily used for tensile strength testing, they can also be employed to evaluate shear strength through specific testing setups, such as shear tests performed on different forms of materials—solid, composite, and thin films.

In China, tensile testers are manufactured by various companies, offering advanced features such as digital displays, computer interfacing, and program control for automated testing. Many of these machines comply with international standards, which makes them integral to research and development, quality control, and compliance testing in different industries.

Testing Methods

There are several methods to test shear strength using tensile testers

china tensile tester shear strength

1. Direct Shear Test This method involves applying a horizontal load on a sample that is held in place. The maximum load applied at the point of failure provides a measure of the shear strength.

2. Punch Shear Test In this test, a punch is used to apply a shearing force to a sample cut from a sheet. The force required to cause the material to shear is recorded, allowing for shear strength calculation.

3. Box Shear Test Used primarily for granular materials, the box shear test evaluates shear strength within a confined area under controlled conditions.

In all these tests, the tensile tester captures data on force, displacement, and, ultimately, the failure mode, providing comprehensive insights into the material’s properties.

Importance of Shear Strength in Industrial Applications

Understanding shear strength is vital in many fields, including construction, automotive, aerospace, and manufacturing. In construction, it informs the design of structural elements like beams and connections to ensure they can withstand forces without failing. In the automotive industry, it helps in the design of safety features and components that are both lightweight and strong.

Moreover, rigorous testing of shear strength during quality control processes ensures that materials used in production meet safety standards and performance criteria, thereby reducing the risk of catastrophic failures.

Conclusion

The China tensile tester serves as a fundamental tool in the measurement of shear strength, contributing significantly to the understanding and application of materials in various engineering fields. With advancements in technology, these testers are becoming more precise, user-friendly, and efficient, facilitating better research and product development. As industries continue to evolve, the importance of reliable shear strength testing will remain paramount in ensuring quality and safety across numerous applications.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy