Custom Solutions for High-Precision Tensile Testers Designed for Your Specific Purchasing Needs

Custom Purchasing Tensile Tester A Comprehensive Guide

In today’s competitive manufacturing landscape, the importance of quality control cannot be overstated. One of the most crucial aspects of quality assurance is material testing, which ensures that the materials used in production meet certain standards and specifications. Among the various testing devices available, tensile testers play a vital role in evaluating the mechanical properties of materials. When it comes to ensuring precision and accuracy, many companies are turning to custom purchasing options for their tensile testing machines. This article explores the benefits and considerations involved in acquiring a custom purchasing tensile tester.

Understanding Tensile Testing

Tensile testing, also known as tension testing, is a method used to determine how materials will react under controlled tension conditions. During this test, a sample material is subjected to a controlled pulling force until it deforms or breaks. The results yield essential data, such as tensile strength, elongation, and yield strength, which are crucial for material selection and engineering processes.

The Need for Custom Solutions

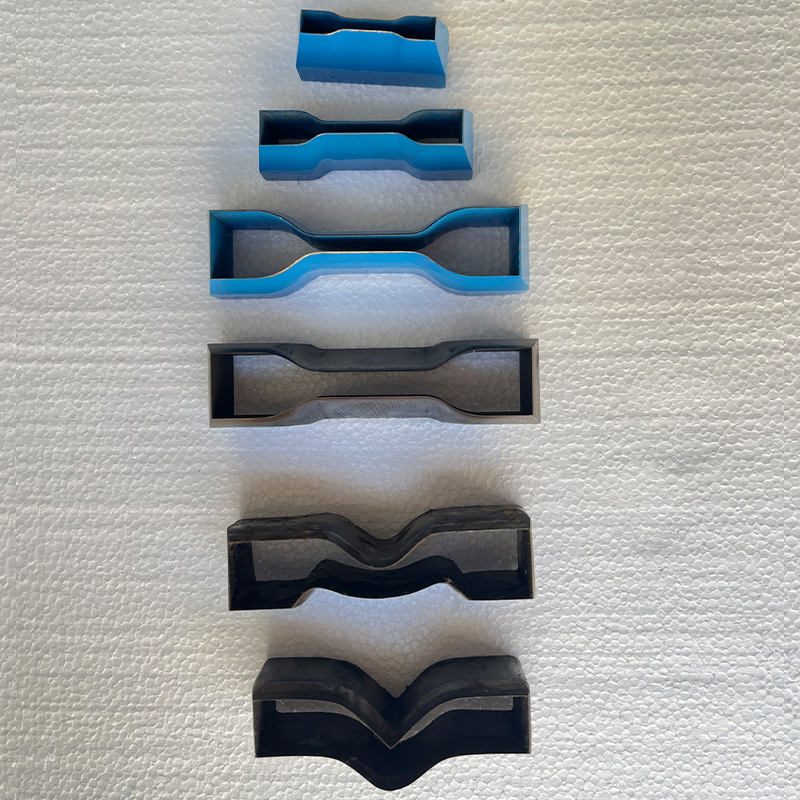

One size does not fit all when it comes to tensile testing. Different industries and applications require specific configurations of testing equipment to fulfill unique requirements. For instance, the materials tested can vary significantly in terms of size, shape, composition, and testing conditions. Custom purchasing tensile testers allow businesses to tailor the machines to meet their specific needs.

1. Customization Options Advanced tensile testers can be customized in several ways, including the selection of grips, load cells, and software packages. Custom grips can accommodate different material shapes and sizes, while specialized load cells can enhance the accuracy of measurements depending on the material characteristics.

2. Enhanced Testing Capabilities By opting for a custom tensile tester, businesses can integrate additional features such as environmental chambers for testing materials under extreme temperatures, or data acquisition systems that provide real-time analysis and reporting.

3. Scalability As companies grow and their testing needs evolve, a custom tensile tester can be built with scalability in mind. This ensures that the equipment can be upgraded to accommodate new materials or testing methods without the need for complete replacement.

custom purchasing tensile tester

Key Considerations for Custom Purchasing

When embarking on the journey to purchase a custom tensile tester, there are several factors that businesses should consider

1. Assessing Requirements Before requesting a custom tensile machine, it is essential to thoroughly assess the specific testing requirements. This includes understanding the types of materials to be tested, the range of loads that will be applied, and any additional features that might enhance the testing process.

2. Vendor Selection Choose a reputable manufacturer or supplier specializing in custom testing equipment. Look for vendors with a proven track record of delivering high-quality products and excellent customer support.

3. Budgeting Custom tensile testers can vary significantly in price based on specifications and features. It is crucial to establish a budget, keeping in mind that investing in high-quality equipment can yield long-term savings and improved testing reliability.

4. Training and Support Ensure that the vendor provides necessary training for personnel and ongoing support for maintenance and troubleshooting. Proper training can minimize the risk of errors and ensure that the equipment is used to its fullest potential.

Conclusion

Custom purchasing tensile testers provide an invaluable solution for businesses seeking precise and reliable material testing. With the ability to tailor specifications, enhance testing capabilities, and scale as needed, these machines can significantly improve quality control processes. By carefully considering requirements, selecting reputable vendors, and planning for budget and support, companies can invest wisely in custom tensile testers that meet their unique needs. This investment not only enhances quality assurance but also contributes to the overall efficiency and success of manufacturing operations.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy