Custom Cable Aging Oven for Enhanced Durability Testing and Performance Evaluation in Electrical Applications

Understanding Custom Cable Aging Ovens Importance and Applications

In the fast-evolving world of electrical engineering and manufacturing, the durability and longevity of cable materials are paramount. One of the essential tools in ensuring the reliability of these materials is the custom cable aging oven. This specialized equipment is designed to simulate the aging process of cables under controlled conditions. By understanding the significance and functionality of custom cable aging ovens, manufacturers can enhance the quality and performance of their products.

What is a Custom Cable Aging Oven?

A custom cable aging oven is an industrial device designed to test the aging characteristics of various cable types and their insulation materials. The aging process involves exposing the cables to elevated temperatures and specific environmental conditions that mimic real-life scenarios over an extended period. The objective is to accelerate the aging process, allowing manufacturers to evaluate how their products will perform as they age. This type of testing is crucial in determining the lifespan and reliability of the cables, ensuring that they can withstand the rigors of their intended applications.

The Importance of Aging Tests

Aging tests provide valuable insights into the performance of cable materials over time. As cables are frequently utilized in environments that expose them to heat, moisture, chemicals, and mechanical stress, understanding how these factors affect durability is critical. By using custom cable aging ovens, manufacturers can

1. Predict Lifespan Accelerated aging tests help forecast how long cables will remain functional under specific conditions, allowing manufacturers to make informed decisions about their products’ expected lifecycle.

2. Identify Weaknesses Testing can reveal potential flaws in materials or designs, enabling engineers to enhance cable resilience and performance before market release.

3. Compliance and Standards Many industries require adherence to strict safety and performance standards. Aging tests conducted in a controlled environment ensure that cables meet these regulations, thereby avoiding liability and enhancing safety.

Key Features of Custom Cable Aging Ovens

Custom cable aging ovens come equipped with a range of features that facilitate effective aging tests

- Temperature Control Precise temperature settings that can be adjusted to simulate various environmental conditions accurately. - Uniform Heat Distribution Ensures that all samples are exposed to the same conditions, leading to reliable and reproducible results.

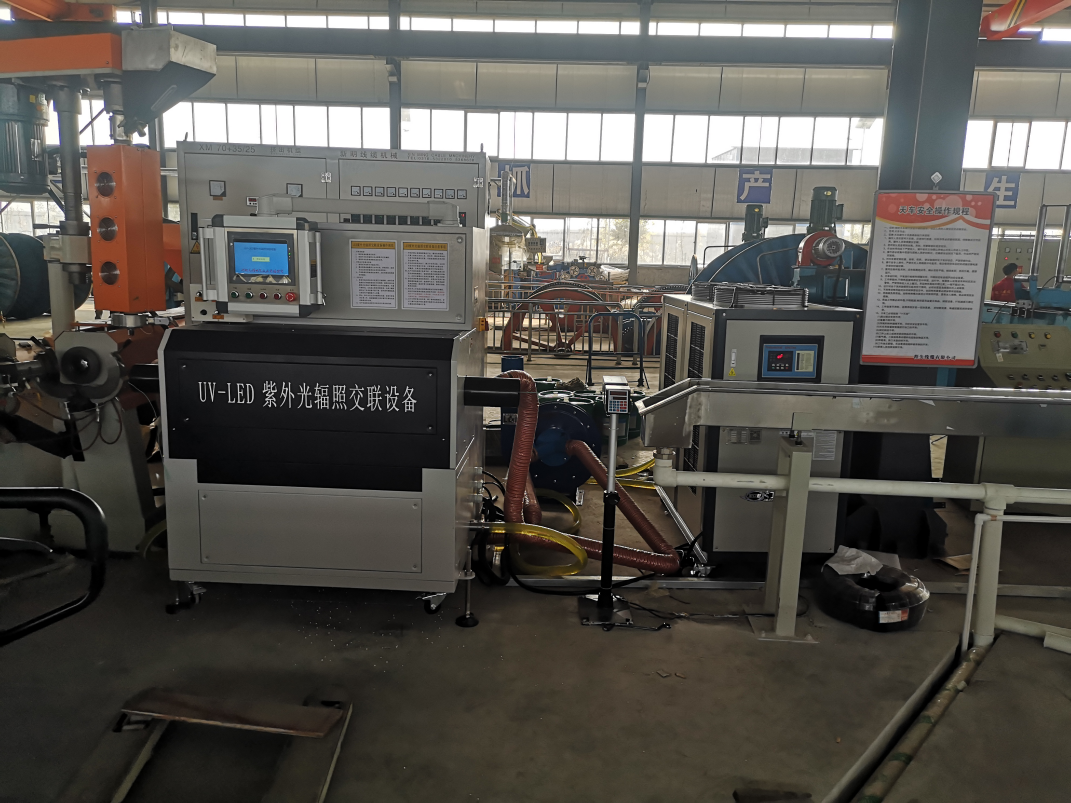

custom cable aging oven

- Humidity Control Some applications require moisture exposure, and custom ovens can integrate humidity control to replicate these conditions.

- Programmable Cycles User-friendly interfaces allow engineers to set specific aging profiles, including temperature, duration, and humidity levels, depending on their testing requirements

.- Data Logging and Analysis Many custom cable aging ovens come with built-in data logging capabilities to track changes in samples over time, aiding in detailed analysis.

Applications of Custom Cable Aging Ovens

The use of custom cable aging ovens is vital in various sectors, including

- Telecommunications Ensuring that communication cables can withstand environmental stresses over time, vital for continuous operation.

- Automotive Industry Testing wires and cables used in vehicles to ensure longevity and safety as they are exposed to extreme temperatures and environmental factors.

- Aerospace Cables used in aircraft and spacecraft must endure rigorous conditions; thus, aging tests are crucial for compliance with stringent safety standards.

- Electrical Utilities Assessing cables used in power generation and distribution systems to prevent failures that can lead to outages.

Conclusion

In summary, custom cable aging ovens are indispensable tools in the manufacturing and engineering sectors. They provide critical insights into how cable materials will perform over time, ensuring that products can endure the challenges of their environments. By investing in advanced aging ovens, manufacturers not only enhance their product quality but also assure customers of their reliability and safety. As technology continues to advance, custom cable aging ovens will play an increasingly important role in the development of innovative and resilient cable solutions.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy