Precision Tester for Constant Temperature Custom Conductor Resistance Measurement

Understanding Custom Conductor Resistance Constant Temperature Testers

In the world of electrical engineering and materials science, the importance of accurately measuring the resistance of conductors cannot be overstated. One of the key tools for performing this measurement is the constant temperature tester, which is specifically designed to maintain a stable temperature during resistance testing. This article will delve into the significance, working principles, and advantages of custom conductor resistance constant temperature testers.

The Significance of Resistance Measurement

Resistance is a fundamental property of electrical conductors, directly influencing their performance in various applications. High resistance can lead to significant energy losses through heat, while low resistance is critical for efficient electrical circuits. Accurate resistance measurements are essential to ensure that materials meet engineering specifications and can operate effectively under varying conditions. This is especially crucial in industries such as automotive, aerospace, and electronics, where even minute deviations can lead to failures.

The Role of Temperature in Resistance Measurement

Resistance in conductors is temperature-dependent; as temperature increases, resistance often increases (especially in metals). This variability warrants the need for strict temperature control during resistance testing. Constant temperature testers are designed to provide a stable thermal environment, ensuring that the resistance measurements taken are accurate and consistent.

Typically, resistance measurements can produce erratic results if temperature fluctuations occur during testing. This is particularly relevant in applications like semiconductor testing, where resistivity must be precisely calibrated. Custom conductor resistance constant temperature testers address this challenge by incorporating thermal management systems that maintain a predetermined temperature, allowing for reliable readings.

Working Principle of Constant Temperature Testers

Custom conductor resistance constant temperature testers operate on a straightforward yet effective principle. They utilize precision temperature control mechanisms, often involving thermoelectric devices or thermocouples, to ensure the sample conductor remains at a specified temperature throughout the testing process.

The testers are equipped with high-resolution measurement circuitry that can deliver accurate resistance readings down to micro-ohms. The setup typically involves placing the conductor in a thermally controlled chamber where ambient temperature is closely monitored and adjusted as needed. Depending on the specifications, some testers may also allow users to set temperature profiles to evaluate resistance across a range of temperatures.

On a technical level, a constant current source is usually employed to produce a stable current through the conductor

. The resultant voltage drop across the conductor is measured, and Ohm's Law (R = V/I) is then used to calculate resistance.Customization Options

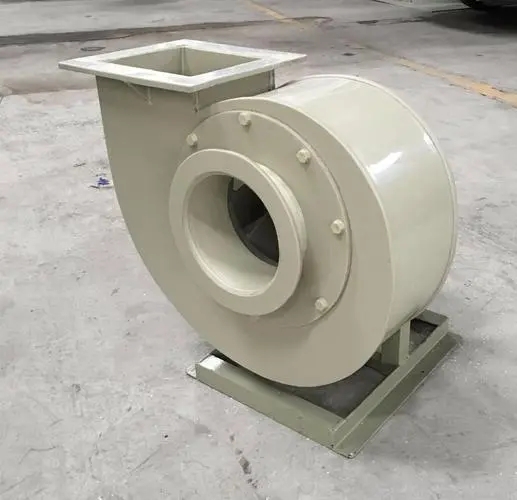

custom conductor resistance constant temperature tester

One of the standout features of modern testing equipment is the ability to customize. Depending on specific requirements, engineers can tailor the design of these testers. Customization can encompass

1. Temperature Range Various applications may require operating at extremely low or high temperatures, prompting the need for testers that can accommodate these ranges. 2. Material Compatibility Depending on the conductors being tested (e.g., copper, aluminum, or even specialty materials like graphene), materials used in the tester’s construct can also be fine-tuned to prevent contamination or reactions. 3. Data Acquisition Systems Advanced testers may integrate sophisticated data logging and analysis software to assist engineers in compiling and interpreting data efficiently.

4. Ergonomics and Portability Depending on the testing environment, some users may prioritize portability or ergonomic designs that facilitate ease of use in various conditions.

Advantages of Using Constant Temperature Testers

Investing in a custom conductor resistance constant temperature tester confers several advantages

- Accuracy With controlled temperature settings, the accuracy of resistance measurements improves significantly.

- Consistency Repeatability of tests leads to reliable data, essential for quality assurance and certification processes.

- Flexibility Custom setups mean that the tester can be adapted for a wide range of materials and testing conditions, making it a versatile tool in the engineer's toolkit.

- Enhanced Performance By maintaining optimal testing conditions, practitioners can achieve better overall performance metrics for their materials.

Conclusion

Custom conductor resistance constant temperature testers play a vital role in ensuring that electrical conductors are appropriately evaluated for their resistance characteristics. By controlling temperature, these testers help eliminate discrepancies that can arise due to environmental variability, leading to reliable and consistent results. As technology advances, the integration of customizable features will only enhance their utility in various scientific and industrial applications, underscoring the importance of precision in resistance measurement.

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy