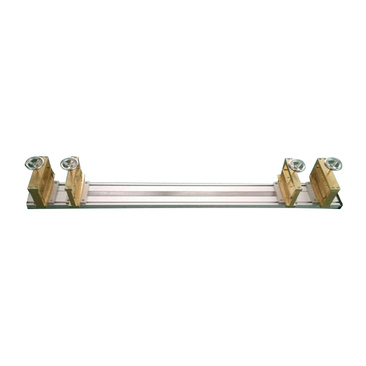

Custom Electronic Universal Testing Machines for Versatile Material Testing Solutions

Exploring the Role of Custom Electronic Universal Testing Machines in Modern Industry

In today's rapidly advancing technological landscape, the demand for precision and reliability in engineering materials has never been more critical. Custom electronic universal testing machines (UTMs) play a pivotal role in this field, enabling industries to conduct a wide range of mechanical tests on materials including metals, plastics, ceramics, and composites. Designed to provide accurate and repeatable results, these machines have become indispensable tools for manufacturers, researchers, and quality control professionals.

Understanding Universal Testing Machines

Universal testing machines are designed to test the tensile and compressive strength of materials. Equipped with advanced electronic control systems, they can apply various loads to a material specimen at different speeds, measuring the material's response in terms of elongation, strain, and deformation. Traditional UTMs typically follow standard testing protocols, but the rise in demand for specialized applications has led to the emergence of custom electronic UTMs.

These custom machines can be tailored to meet specific testing requirements, such as load capacity, test speeds, and environmental conditions. This adaptability ensures that industries can obtain precise data relevant to their unique materials and processes, thereby enhancing product quality and safety.

Applications of Custom Electronic UTMs

Custom electronic UTMs are utilized across various industries, including aerospace, automotive, construction, and electronics. In the aerospace sector, for instance, maintaining stringent quality standards is paramount. Engineers can use custom testing machines to test composite materials used in aircraft components, ensuring that they meet safety and performance criteria under extreme conditions.

In the automotive industry, manufacturers employ UTMs to evaluate the durability and performance of materials used in vehicle production. By customizing testing protocols, they can simulate real-world conditions, gathering data that informs design choices and enhances safety features.

custom electronic universal testing machine

The construction sector also benefits from custom UTMs, particularly when testing materials such as concrete and steel

. Understanding the tensile strength and ductility of these materials helps engineers design safer buildings and infrastructures.Furthermore, in electronics, custom UTMs play a crucial role in assessing the mechanical properties of circuit boards and other components. They ensure that products can withstand physical stress during assembly and operation, ultimately leading to higher reliability and customer satisfaction.

Advantages of Customization

One of the primary advantages of custom electronic UTMs is their ability to streamline the testing process. By integrating specific features, such as advanced data acquisition systems and specialized grips, manufacturers can significantly reduce testing time while improving accuracy. Real-time data processing capabilities allow engineers to analyze results instantly, facilitating quicker decision-making in product development.

Customization also extends to software interfaces, enabling users to tailor data analysis tools according to their testing protocols. This flexibility ensures that industries can adopt the latest testing methodologies without the need for entirely new equipment.

Moreover, custom UTMs can be designed to operate within controlled environments—such as temperature or humidity chambers—allowing for comprehensive testing under varying conditions. This is particularly important for industries where materials must perform reliably in extreme climates.

Conclusion

In conclusion, custom electronic universal testing machines are essential assets for industries that prioritize material performance and quality. Their flexibility, accuracy, and adaptability make them invaluable tools that drive innovation and safety across various sectors. As technology continues to evolve, the role of custom UTMs will undoubtedly expand, paving the way for new testing methodologies that enhance our understanding of materials and their applications in the modern world. Investing in such advanced testing solutions ensures that industries not only meet current standards but also push the boundaries of what's possible in material science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy