iec60811 company

Understanding IEC 60811 and Its Significance in the Cable Industry

The International Electrotechnical Commission (IEC) has established various standards to ensure safety, efficiency, and reliability in electrical and electronic devices. Among these standards is IEC 60811, which specifically addresses the methods for testing insulating and sheathing materials of electrical cables. This standard plays a crucial role in the cable industry by ensuring that materials used in the production of cables can withstand environmental stresses and perform reliably over time.

Background of IEC 60811

IEC 60811 was introduced to provide a comprehensive framework for assessing the physical and chemical properties of insulating materials and sheathing used in electric cables. The standard covers a wide range of tests that evaluate parameters such as thermal resistance, moisture absorption, and mechanical properties. By detailing standardized testing methods, IEC 60811 aims to facilitate international trade and enhance safety standards worldwide.

With the increasing demand for high-performance electrical cables in various applications—from residential wiring to advanced telecommunications—having a robust set of guidelines is essential. IEC 60811 helps manufacturers ensure that their products meet the necessary durability and safety criteria needed for both domestic and industrial use.

Key Testing Methods Defined in IEC 60811

IEC 60811 encompasses several important test methods, each designed to determine specific characteristics of cable materials. Some of the notable tests include

1. Thermal Aging This test involves exposing the materials to elevated temperatures for extended periods to simulate long-term use conditions. It helps determine how well the material can resist heat and maintain its properties over time.

iec60811 company

2. Moisture Resistance Cables often experience exposure to moisture, which can lead to degradation of insulating materials. IEC 60811 outlines tests to measure the water absorption and the effects of moisture on the material's properties.

3. Mechanical Properties Evaluation This includes tests for tensile strength, elongation, and impact resistance. These characteristics are critical for ensuring that cables can withstand physical stresses during installation and operation.

4. Chemical Resistance Since cables may come into contact with various chemicals, IEC 60811 prescribes tests to evaluate the resilience of materials against common chemicals they might encounter in real-world applications.

Benefits of Adhering to IEC 60811

For manufacturers, adherence to IEC 60811 not only ensures compliance with international standards but also enhances product quality and customer trust. Production processes aligned with these standards can lead to more consistent quality control and minimize the risk of product failures. Consequently, this supports manufacturers in achieving competitive advantages in the marketplace.

Moreover, IEC 60811 fosters transparency and reliability. Customers can have confidence in the performance of the cables they purchase, knowing that substantial testing validates their quality. This is particularly important in industries that require rigorous standards, such as construction, aerospace, and energy.

Conclusion

In conclusion, IEC 60811 serves as a fundamental standard that underpins the manufacturing and testing of insulating and sheathing materials used in electrical cables. By establishing a set of rigorous testing methods, it ensures that materials can perform effectively in various environments and over extended periods. As the demand for high-performance cables continues to grow, adhering to IEC 60811 will remain vital for manufacturers seeking to ensure safety, reliability, and compliance with international standards. The standard not only contributes to improved product quality but also enhances customer satisfaction and trust in the products available in the market. Through continuous adherence to these standards, the cable industry can look forward to innovations and advancements that will support the evolving needs of technology and infrastructure development.

-

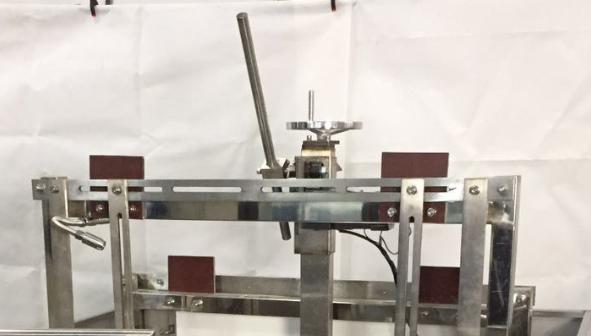

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy