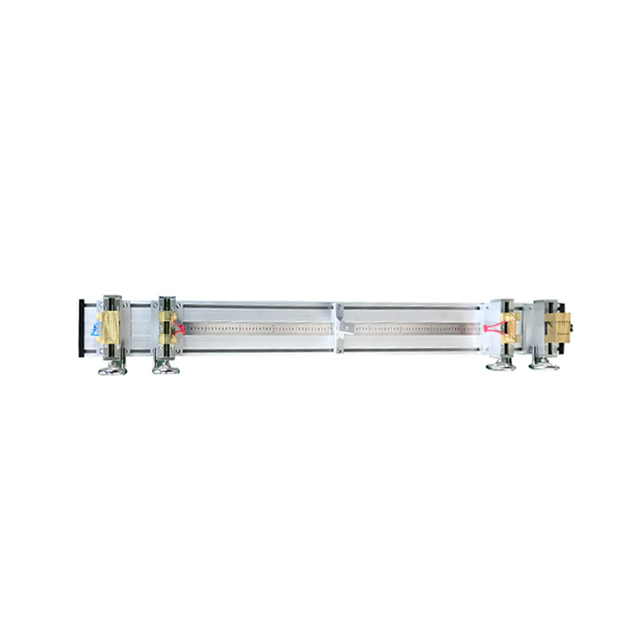

computer control universal tensile testing machine

Advancements in Computer-Controlled Universal Tensile Testing Machines

In the realm of materials testing, the computer-controlled universal tensile testing machine represents a significant technological advancement. These machines have become essential tools in the assessment of material properties, providing both accuracy and efficiency in testing procedures. With the increasing complexity of modern materials, the ability to conduct precise tensile tests has never been more critical.

At its core, a universal tensile testing machine is designed to measure how materials respond to various forces, specifically tensile (pulling) and compressive (pushing) loads. Traditionally, these tests required manual intervention, but the integration of computer control systems has revolutionized this process. By automating the operation, these machines can perform a range of tests, including tensile strength, yield strength, elongation, and reduction in area, with enhanced precision.

The computerized control system allows for real-time data acquisition and analysis. This means that as a sample is tested, the machine continually measures the load and elongation, providing instant feedback. Data collected can be displayed graphically, enabling engineers and researchers to visualize material performance instantly. Furthermore, the software associated with these machines often includes advanced features like statistical analysis tools, which help in interpreting data efficiently.

computer control universal tensile testing machine

One of the standout features of computer-controlled universal tensile testing machines is their programmability. Users can set specific testing protocols tailored to their materials and requirements. This flexibility is invaluable in research environments where various materials must be tested under different conditions or in quality control settings where standard tests need to be repeated consistently.

Another significant advantage is the enhanced safety protocols embedded in the software. The machines can be programmed to halt testing automatically if predetermined limits are exceeded, ensuring the safety of both the operator and the equipment. This level of control significantly reduces the risk of accidents, particularly when dealing with high-strain materials that may behave unpredictably at the limits of their capabilities.

As industries continue to evolve, the demand for reliable materials testing is growing. The computer-controlled universal tensile testing machine stands at the forefront of this demand, making it an indispensable asset in various sectors, including aerospace, automotive, construction, and biomedical fields. By providing critical insights into material behavior, these machines contribute to innovation and excellence in material design and quality assurance.

In conclusion, the evolution of computer-controlled universal tensile testing machines marks a significant shift in materials testing methodology. Their ability to combine precision, safety, and adaptability has transformed traditional testing paradigms, paving the way for new discoveries and advancements in material science. As technology continues to advance, we can expect these machines to incorporate even more sophisticated features, further enhancing their role in research and industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy