Creating a Comprehensive Digital Profile Projector for Enhanced User Experience and Engagement Analysis

Understanding the Digital Profile Projector A Revolution in Precision Measurement

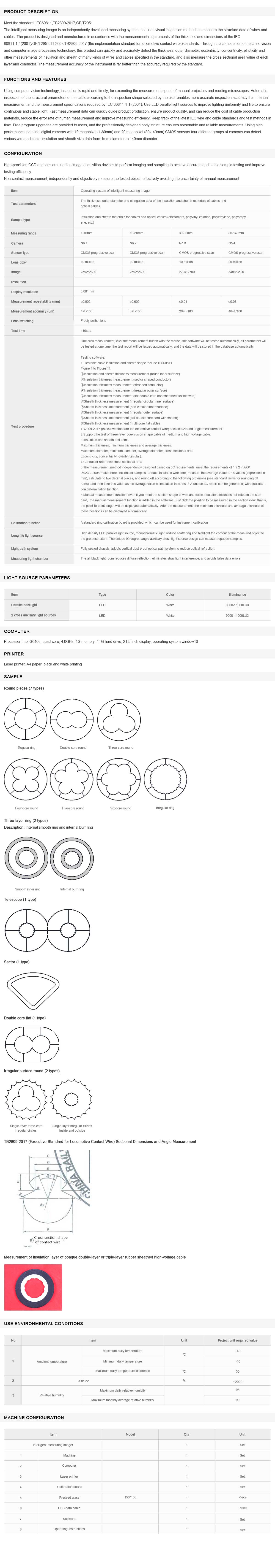

In today’s fast-paced manufacturing world, precision and accuracy are paramount. As industries continue to evolve, the need for advanced measurement tools has become increasingly critical. One such innovative tool that has gained significant popularity in manufacturing and quality control is the digital profile projector. This sophisticated device combines optics and digital technology to enhance the measurement and inspection of complex parts and components, ensuring that they meet stringent specifications.

A digital profile projector, often referred to as an optical comparator, uses a projector system to magnify the silhouette of an object onto a screen. Unlike traditional profile projectors that rely solely on analog technology, digital profile projectors incorporate advanced digital imaging techniques. This integration enables users to capture images, store data, and perform intricate measurements with a new level of precision that was previously unattainable.

The operation of a digital profile projector begins with placing the part or component on a glass stage beneath a beam of light. An optical lens system then projects an enlarged shadow of the part onto a flat screen. This projection allows operators and quality control personnel to visually inspect the profile of the object against predetermined specifications. However, what sets digital profile projectors apart is their ability to utilize digital cameras to capture these images for further analysis.

One of the most significant advantages of digital profile projectors is their capability for automated measurements. Users can utilize advanced software to analyze the captured images, enabling the measurement of angles, dimensions, and radii with speed and accuracy. This automation reduces human error and optimizes the measurement process, making it significantly faster than manual methods. Furthermore, the software often includes features for statistical analysis and reporting, making it easy to document findings and track quality over time.

digital profile projector

Another feature that enhances the utility of digital profile projectors is the ease of use. With user-friendly interfaces and straightforward operation, these devices allow operators to transition from traditional measurement methods to digital technologies seamlessly. Many digital profile projectors are also equipped with programmable features, enabling users to set up measurement routines that can be replicated across multiple parts, further enhancing efficiency.

In addition, digital profile projectors have become essential tools in various industries, including automotive, aerospace, medical device manufacturing, and electronics. In these sectors, the ability to measure intricate geometries accurately is not merely advantageous; it is a necessity. For instance, in the aerospace industry, the tolerances for components are incredibly tight, and any deviation can lead to catastrophic failures. Digital profile projectors help ensure that parts are manufactured within those necessary specifications.

Furthermore, as the demand for faster production times increases, utilizing a digital profile projector can significantly cut down on inspection time while maintaining high-quality standards. This balance of speed and accuracy is crucial in meeting the market’s ever-changing demands.

In conclusion, the digital profile projector is an indispensable tool in the modern manufacturing landscape. By merging optical technology with digital advancements, these devices have transformed how manufacturers and quality control experts measure, inspect, and ensure that components meet stringent dimensional criteria. As industries continue to embrace automation and digital solutions, the role of digital profile projectors in enhancing precision and efficiency will only become more prominent in the years to come. Their ability to streamline operations while maintaining high accuracy makes them an essential investment for any forward-thinking manufacturing entity.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy