laboratory balance in density factories

The Role of Laboratory Balances in Density Factories

In the modern world of manufacturing and quality control, the precision of measurements is paramount. One critical aspect of this precision is ensuring the accurate measurement of density, which is essential in various industries, including pharmaceuticals, food and beverage, and materials science. Laboratory balances play a crucial role in density determination within these environments, providing the foundational measurements necessary for product consistency and quality.

Understanding Density and Its Importance

Density, defined as the mass per unit volume of a substance, can significantly influence the properties and behavior of materials. For instance, in pharmaceutical manufacturing, the density of a compound can affect its solubility, bioavailability, and stability. In the food industry, density plays a role in product texture and customer perception. Therefore, precise density measurements are vital for compliance with regulatory standards and for maintaining customer satisfaction.

How Laboratory Balances Aid in Density Measurement

Laboratory balances are essential tools for measuring mass accurately, and they come in various types, including analytical balances and precision balances. Analytical balances, known for their high precision and sensitivity, typically have readability down to 0.0001 grams, making them ideal for applications requiring precise mass measurements.

To calculate density, one needs to measure both the mass and volume of a substance. The formula for density is straightforward

\[ \text{Density} = \frac{\text{Mass}}{\text{Volume}} \]

In density factories, laboratory balances are used to determine the mass of the substance, which is a critical first step in the density calculation. However, measuring volume can be more complex, often requiring additional equipment such as graduated cylinders, pycnometers, or digital volume meters.

Best Practices for Using Laboratory Balances

To ensure accuracy and reliability in density measurements, certain best practices should be followed when using laboratory balances

.laboratory balance in density factories

1. Calibration Regular calibration of balances is necessary to maintain accurate measurements. Calibration adjusts the balance's readings concerning a standard mass, ensuring precision over time.

2. Environmental Control Laboratory balances are sensitive to environmental factors such as temperature fluctuations, air currents, and vibrations. Therefore, maintaining a controlled environment helps in achieving consistent results.

3. Sample Preparation Proper sample preparation is critical. Substances should be free from moisture, impurities, and any other factors that could affect their mass. When measuring liquids, it's important to account for the evaporative behavior, which can lead to inaccuracies.

4. Use of Appropriate Techniques When measuring small quantities, it's beneficial to use techniques such as tare weighing, where the balance is zeroed with the container before adding the sample. This minimizes the uncertainty associated with the container's weight.

5. Documentation and Repeatability Keeping thorough documentation of measurements, including the conditions under which they were taken, is essential for later verification and quality control processes. Repeating measurements can help identify inconsistencies and ensure the accuracy of results.

The Future of Laboratory Balances in Density Measurement

As technology advances, laboratory balances are becoming increasingly sophisticated. Digital balances equipped with software can now automatically calculate density by integrating mass and volume measurements, reducing the chance of human error. Bluetooth connectivity and data logging features allow for easier data management and analysis, further enhancing the efficiency of density factories.

Moreover, the integration of artificial intelligence and machine learning could revolutionize how density is measured and managed. Intelligent systems may predict trends in material properties or recommend adjustments in production processes, ensuring high-quality outputs consistently.

Conclusion

In summary, laboratory balances are indispensable instruments in density factories, playing a pivotal role in ensuring accurate density measurements, which are crucial for maintaining product quality across various industries. By adhering to best practices and embracing technological advancements, manufacturers can enhance precision and efficiency, ultimately leading to better quality products and improved customer satisfaction. The meticulous measurement of density, supported by an array of modern laboratory balances, is essential for navigating the complexities of today’s manufacturing landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

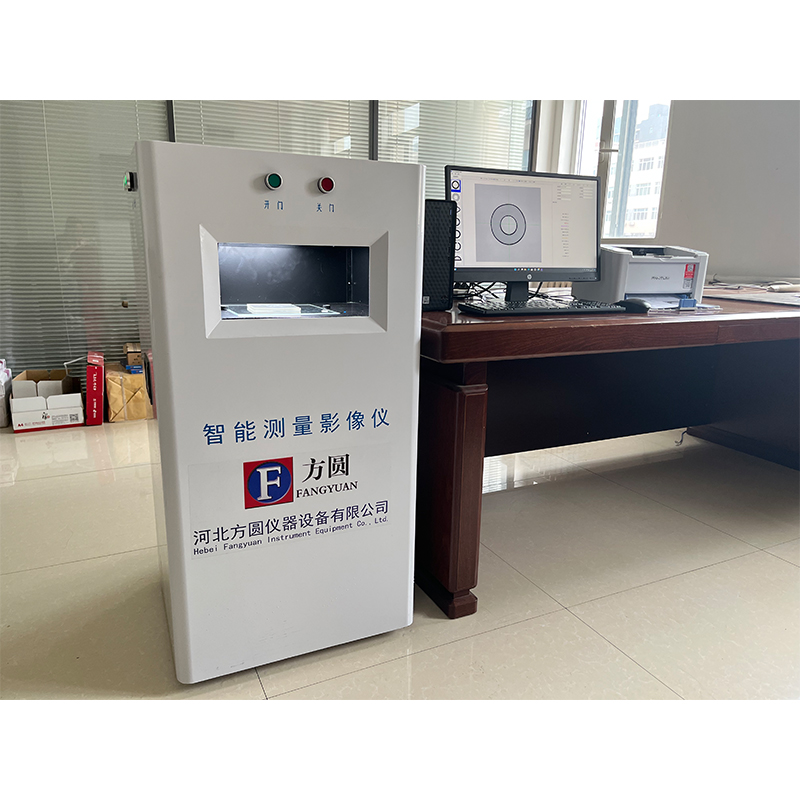

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy