Manufacturers of Machines for Testing Cable Durability Through Repeated Bending Procedures

Cable Repeated Bending Test Machine Factories Ensuring Quality and Durability

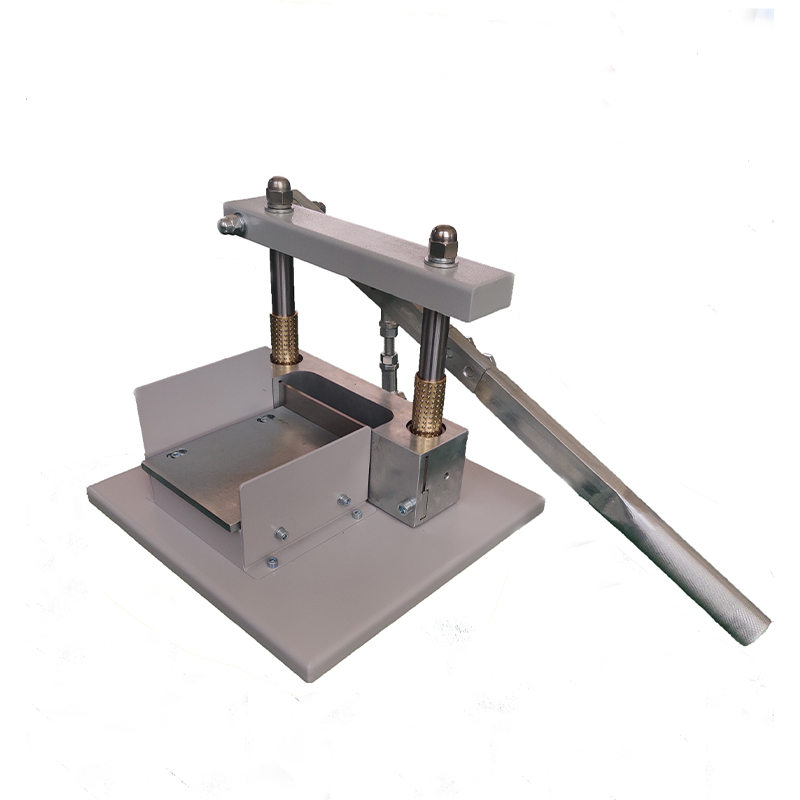

In the modern manufacturing landscape, the integrity of cables used in various applications is paramount. Cables are subjected to a multitude of stresses, and their performance directly impacts the safety and efficiency of the products they serve. This is where the cable repeated bending test machine comes into play. Factories that specialize in producing these testing machines are vital to ensuring that cables meet industry standards for durability and reliability.

Understanding Cable Repeated Bending Tests

The repeated bending test simulates the flexing motion a cable undergoes during its operational lifespan. Cables are often routed through tight spaces, subjected to repetitive movements, and required to withstand environmental conditions. The aim of the test is to replicate these stresses in a controlled setting to evaluate how cables perform over time. This process helps manufacturers identify potential failure points, material weaknesses, and the overall lifespan of their cables.

The Role of Testing Machine Factories

Factories that manufacture cable repeated bending test machines play a crucial role in the quality assurance process. These specialized facilities are equipped with advanced technology and expertise to design and build machines that can accurately replicate the conditions cables face in real-world applications. The machines are engineered to accommodate various cable types and sizes, ensuring versatility and reliability in testing.

One of the key aspects of these factories is their commitment to precision engineering. High-quality machines are essential for producing consistent and repeatable results. This means that testing machines must be built with high-fidelity components, precise control systems, and robust materials that can withstand the rigors of continuous testing. Factories often invest in research and development to improve their machines, integrating feedback from users to enhance functionality and effectiveness.

Key Features of Quality Testing Machines

When evaluating cable repeated bending test machines, several features are essential for effective testing.

cable repeated bending test machine factories

1. Flexibility The ability to test different cable sizes and types is crucial. A well-designed machine should have adjustable fixtures that can accommodate various cable diameters and materials.

2. Control Systems Advanced control systems allow operators to customize test parameters, replicating specific bending angles, frequencies, and cycles. This adaptability ensures that tests closely mimic real-world conditions.

3. Data Capture and Analysis Modern testing machines often come equipped with data logging capabilities, allowing for the collection of performance metrics during testing. This data is invaluable for manufacturers looking to refine their products and improve quality.

4. Durability Since these machines are used extensively, they must be built to last. High-quality construction materials and robust designs minimize maintenance needs and ensure longevity.

The Importance of Compliance and Standards

Testing machines from reputable factories not only meet customer expectations but also comply with industry standards. Many cables must pass specific tests outlined by regulatory bodies. Factories producing testing machines ensure that their products adhere to these standards, enabling manufacturers to certify their cables' performance and safety.

Conclusion

Cable repeated bending test machine factories are at the forefront of ensuring cable quality and durability in various industrial applications. By providing manufacturers with the necessary tools to conduct thorough testing, these factories help ensure that cables can withstand the demands of modern use. The investment into cutting-edge technology and adherence to industry standards not only enhances the safety and reliability of cable products but also promotes trust among consumers and industries that rely on these essential components. As technology continues to evolve, these factories will play a critical role in shaping the future of cable manufacturing and testing.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy