Top Suppliers for Measurement Projectors in the Precision Measurement Industry

The Importance of Measurement Projectors in Manufacturing and Quality Control

In the fast-paced world of manufacturing and quality control, precision and accuracy are of paramount importance. One tool that has gained significant recognition in ensuring the quality and dimensional accuracy of parts and components is the measurement projector. As various industries strive for excellence, understanding the role of measurement projectors and sourcing them from reliable suppliers has become crucial.

What is a Measurement Projector?

A measurement projector, also known as an optical comparator, is a precision measuring instrument that utilizes a light source to project the silhouette of an object onto a screen. This projection allows operators to examine and measure the dimensions of the part against a predetermined standard or blueprint. It's particularly useful for checking complex shapes and difficult-to-measure geometries, commonly found in industries such as aerospace, automotive, and manufacturing.

The working principle of a measurement projector is relatively straightforward. The device projects the shadow of a part onto a screen, where precise measurements can be taken. Most measurement projectors include graduated measurement scales, enabling users to obtain accurate readings without additional equipment. Furthermore, modern measurement projectors often come equipped with digital readouts, adding to their functionality and ease of use.

Why Measurement Projectors Matter

The role of measurement projectors in the manufacturing process cannot be understated. Here are several reasons why these devices are essential

1. Precision and Accuracy Measurement projectors provide a reliable method for inspecting the dimensions of manufactured parts, ensuring that they meet quality standards and specifications. By projecting actual parts against a defined set of criteria, manufacturers can quickly identify any discrepancies, enabling immediate corrections.

2. Enhancing Production Efficiency With the rapid pace of production in today’s manufacturing environments, the ability to quickly verify part dimensions can significantly increase efficiency. Measurement projectors allow for swift inspections, minimizing downtime and ensuring ongoing productivity.

3. Versatility in Applications Measurement projectors can be used to measure a variety of components, from simple to complex geometries. Whether the application involves checking angles, radii, or other geometric features, these tools remain versatile and effective.

4. Quality Assurance Implementing measurement projectors into quality control processes helps manufacturers maintain high standards. Consistent quality checks can prevent defective products from reaching consumers, enhancing the brand's reputation and reducing costs associated with returns and repairs.

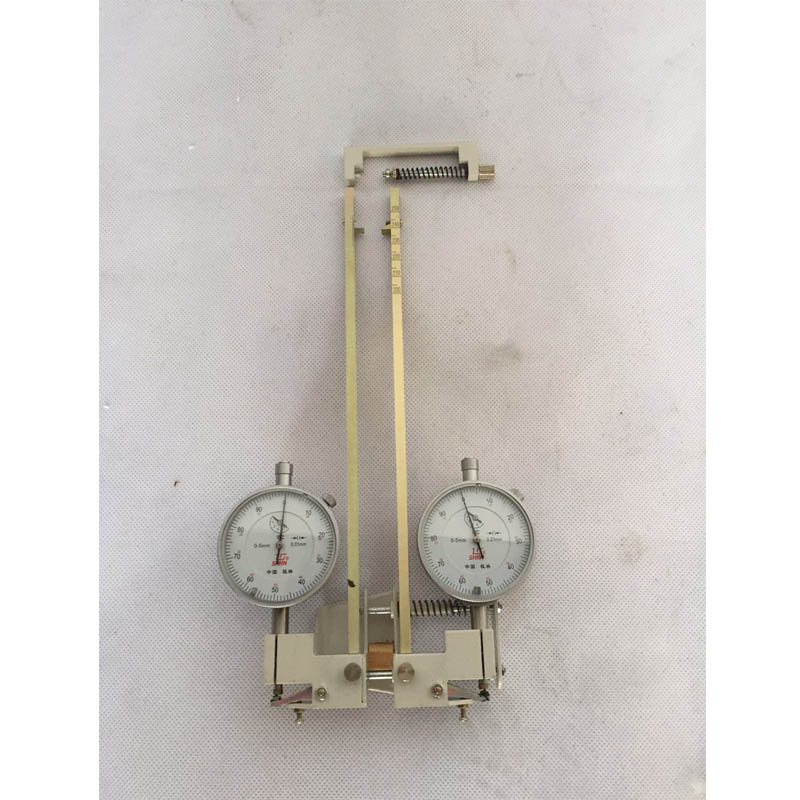

measurement projector suppliers

5. Ease of Use Compared to other measuring instruments, measurement projectors are user-friendly and do not require extensive training. Operators with basic measuring skills can proficiently utilize these tools, facilitating smoother operations on the production floor.

Sourcing Measurement Projectors

Given their significance, finding the right supplier of measurement projectors is critical. Businesses should consider the following factors when selecting a supplier

1. Reputation Look for suppliers who have established a strong reputation in the industry. Reviews, recommendations, and testimonials can be invaluable resources in your search.

2. Quality of Equipment Ensure that the measurement projectors offered meet industry standards and quality certifications. High-quality equipment translates into reliable performance and longevity.

3. Customer Support A good supplier will provide robust customer support, assisting with equipment installation, calibration, maintenance, and operational questions.

4. Customization Options Some applications may require specific features or capabilities. A supplier that offers customization of their measurement projectors can better accommodate your unique needs.

5. Pricing and Value While cost is an important factor, it should not be the only consideration. Evaluate the overall value offered, considering the quality of the product and the level of support provided.

Conclusion

Measurement projectors play an essential role in ensuring product quality and precision in manufacturing processes. Their ability to deliver accurate measurements, improve efficiency, and enhance quality assurance makes them indispensable tools. Therefore, selecting a reputable supplier is crucial for businesses aiming to integrate these instruments into their operations. As industries continue to evolve, the significance of measurement projectors will likely only increase, making them a worthy investment for any quality-conscious manufacturer.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy