UV Crosslinking Equipment Suppliers for High-Quality Manufacturing Solutions and Innovations

The Importance of UV Crosslinking Equipment An Overview of Manufacturers and Their Innovations

Ultraviolet (UV) crosslinking technology has become an indispensable process in various industries, particularly in the fields of coatings, adhesives, and printing. This method enhances the durability and performance of materials through the formation of chemical bonds that improve resistance to heat, solvents, and wear. As the demand for high-quality, durable products continues to rise, the role of UV crosslinking equipment manufacturers becomes increasingly pivotal. This article explores the significance of these manufacturers and the innovations they bring to the industry.

Understanding UV Crosslinking Technology

UV crosslinking involves exposing materials to ultraviolet light, which triggers a chemical reaction that bonds polymer chains together. This process results in a robust network of materials that exhibit superior properties compared to conventional options. Industries such as automotive, electronics, and medical devices leverage UV crosslinking for its rapid curing times and enhanced product performance.

The need for reliable and efficient UV crosslinking equipment has become paramount as companies seek to optimize production processes and meet stringent quality standards. As such, manufacturers are constantly innovating to provide state-of-the-art solutions that cater to diverse applications.

Innovations in UV Crosslinking Equipment

Leading UV crosslinking equipment manufacturers are at the forefront of technological advancements in this field

. They focus on several key areas1. Customization and Versatility Manufacturers are developing equipment that can be tailored to meet specific application requirements. This includes adjustable curing speeds, variable energy outputs, and compatibility with various substrates. Customization allows businesses to optimize their production lines for different materials and product specifications.

2. Energy Efficiency As sustainability becomes a priority, manufacturers are innovating to create energy-efficient UV crosslinking systems. Many of these new systems minimize energy consumption without compromising on performance, aligning with global efforts to reduce carbon footprints and promote greener manufacturing processes.

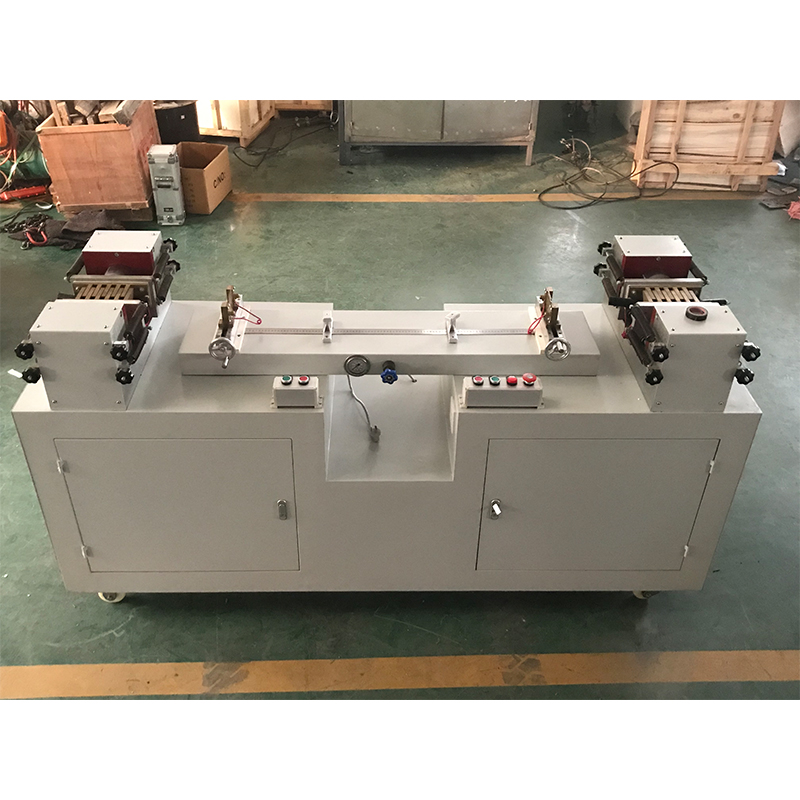

uv crosslinking equipment manufacturer

3. Safety Features Safety is a critical aspect of UV crosslinking equipment design. Manufacturers are integrating advanced safety features, such as improved shielding and monitoring systems, to protect operators from UV exposure. These technologies ensure a safer workplace while complying with regulatory standards.

4. Integration of Smart Technologies The advent of Industry 4.0 has led manufacturers to incorporate smart technologies in their UV crosslinking equipment. Features like IoT connectivity allow for real-time monitoring and data analysis. This integration helps manufacturers improve process efficiency, reduce downtime, and enhance overall production capabilities.

5. Enhanced Curing Techniques Recent advancements in UV curing technology have led to the development of LED UV systems. These systems provide numerous benefits, including longer bulb life, lower heat emission, and quicker warm-up times compared to traditional mercury-based systems. LED technology is revolutionizing the industry by offering more effective and eco-friendly solutions.

Choosing the Right Manufacturer

When selecting a UV crosslinking equipment manufacturer, businesses should consider several factors

- Reputation and Experience Established manufacturers with a strong track record are more likely to provide reliable equipment and support. - Customer Reviews Feedback from other users can provide insight into the performance and reliability of the equipment. - After-Sales Support A manufacturer that offers comprehensive support, including training and maintenance, ensures that businesses can effectively utilize their equipment.

Conclusion

The role of UV crosslinking equipment manufacturers is crucial in enhancing the quality and durability of products across various industries. Through continuous innovation, these manufacturers are not only meeting the growing demands of the market but also contributing to more sustainable manufacturing practices. As this technology evolves, it will likely lead to even more advanced applications, further solidifying the importance of UV crosslinking in modern production processes.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy