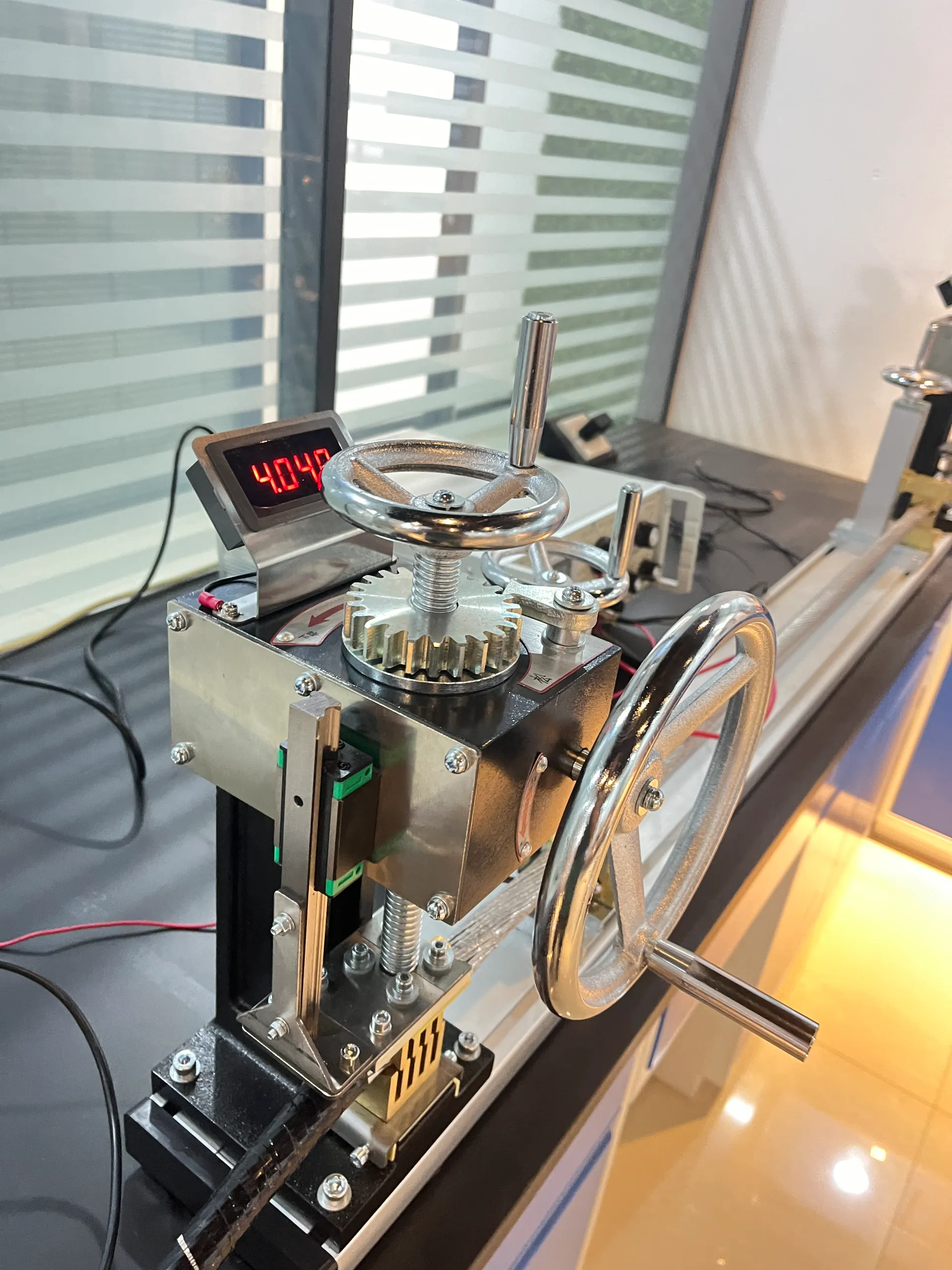

custom tensile tester for sale

Custom Tensile Tester for Sale Understanding the Importance of Material Testing Equipment

In the realm of material science and engineering, the ability to accurately assess the mechanical properties of materials is paramount. Tensile testing is a fundamental method employed to measure the strength and ductility of materials. With the growing demand for high-quality testing equipment, custom tensile testers for sale have gained popularity among manufacturers, researchers, and testing laboratories. This article delves into the significance of tensile testers, the benefits of customized solutions, and what to consider when purchasing a tensile tester.

What is a Tensile Tester?

A tensile tester, also known as a universal testing machine (UTM), is an essential piece of equipment designed to evaluate the tensile strength of a material. It does so by applying a controlled tensile force to a material specimen until it deforms or breaks. The data collected during this testing process includes measurements of yield strength, ultimate tensile strength, elongation, and reduction of area. These parameters are crucial for understanding how materials will perform under stress in real-world applications.

The Need for Customization

While standard tensile testers can meet the basic requirements of material testing, many industries require equipment tailored to specific needs. Custom tensile testers offer several advantages

1. Specific Testing Requirements Different materials and applications have unique testing requirements. For example, composites might need a different setup compared to metals. Custom tensile testers can be designed with specific grips, fixtures, and loading procedures that suit the material type being tested.

2. Increased Accuracy Tailored designs can enhance measurement precision. Custom machines can incorporate advanced sensors and software tailored for certain applications, ensuring that results are both accurate and repeatable.

3. Enhanced Features Many industries demand additional features such as high-speed testing, environmental controls, or automation capabilities. Custom tensile testers can be equipped with these options to meet specific industry standards and testing protocols, increasing efficiency and throughput.

4. Space Optimization In many laboratories or production environments, space is at a premium. Custom tensile testers can be designed to fit within specific spatial constraints while maintaining full functionality, allowing for better use of available space.

custom tensile tester for sale

Factors to Consider When Purchasing a Custom Tensile Tester

When considering the purchase of a custom tensile tester, several factors should be taken into account

1. Material Types Identify the primary materials you will be testing, as well as any additional materials that may require testing in the future. This will guide the specifications for your tensile tester.

2. Testing Standards Ensure that the tensile tester complies with relevant international and industry standards, such as ASTM, ISO, or others specific to your field.

3. Technical Specifications Consider the required load capacity, speed of testing, and measurement accuracy. Discuss these technical specifications with manufacturers to ensure they align with your testing needs.

4. Software and Data Analysis A good tensile tester should come with robust software for data analysis and reporting. Check for user-friendly interfaces, capability for statistical analysis, and data export options.

5. Support and Maintenance After the purchase, ongoing support and maintenance are crucial. Choose suppliers who offer comprehensive service packages, including training, calibration, and repair services.

6. Budget Pricing can vary significantly between standard and custom solutions. It is important to set a realistic budget that includes not only the initial purchase but also ongoing maintenance and operational costs.

Conclusion

Investing in a custom tensile tester is a strategic decision that can greatly enhance your materials testing capabilities. By understanding your specific needs and considering the above factors, you can ensure that your investment will provide long-term value. Whether in research, quality control, or production environments, a well-designed tensile tester will equip you with the essential data needed to ensure the performance and reliability of your materials. As industries continue to evolve, having the right testing equipment becomes not just an advantage, but a necessity in maintaining competitive edge and ensuring safety.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy