High-Quality Computer-Controlled Tensile Strength Testing Equipment from Leading Manufacturers

The Rise of Computer-Controlled Tensile Strength Testers in Manufacturing

In the ever-evolving landscape of manufacturing and material testing, computer-controlled tensile strength testers have emerged as vital tools for ensuring the quality and durability of materials used in various industries. These sophisticated devices are specifically designed to measure the tensile strength, elongation, and yield properties of materials under stress, providing manufacturers with critical data that contribute to product development and quality assurance.

Understanding Tensile Strength Testing

Tensile strength testing involves applying a controlled force to a material sample until it deforms or breaks. This process yields essential information about the material's behavior under load, including its elastic limit, ultimate tensile strength, and the point at which it fractures. Such insights are crucial for manufacturers who need to guarantee the performance of their products, whether they are producing metal components, polymers, textiles, or any other materials.

Traditionally, tensile strength testing was a manual process, often involving less precise methods that could lead to variability in results. However, the introduction of computer-controlled systems has revolutionized this testing approach. These modern machines are equipped with advanced software that allows for precise control of testing parameters, automated data collection, and sophisticated analysis capabilities.

Advantages of Computer-Controlled Systems

1. Precision and Accuracy One of the primary benefits of computer-controlled tensile strength testers is their ability to provide highly accurate results. Automated systems minimize human error, ensuring that measurements are consistent and reliable. This precision is particularly important in industries such as aerospace and automotive, where material integrity is paramount.

2. Efficiency Automated tensile testing systems significantly reduce the time required for testing. Traditional methods might require manual adjustments and frequent monitoring, while computer-controlled machines can run tests continuously, gathering data and generating reports with minimal intervention. This efficiency allows manufacturers to increase throughput and shorten product development cycles.

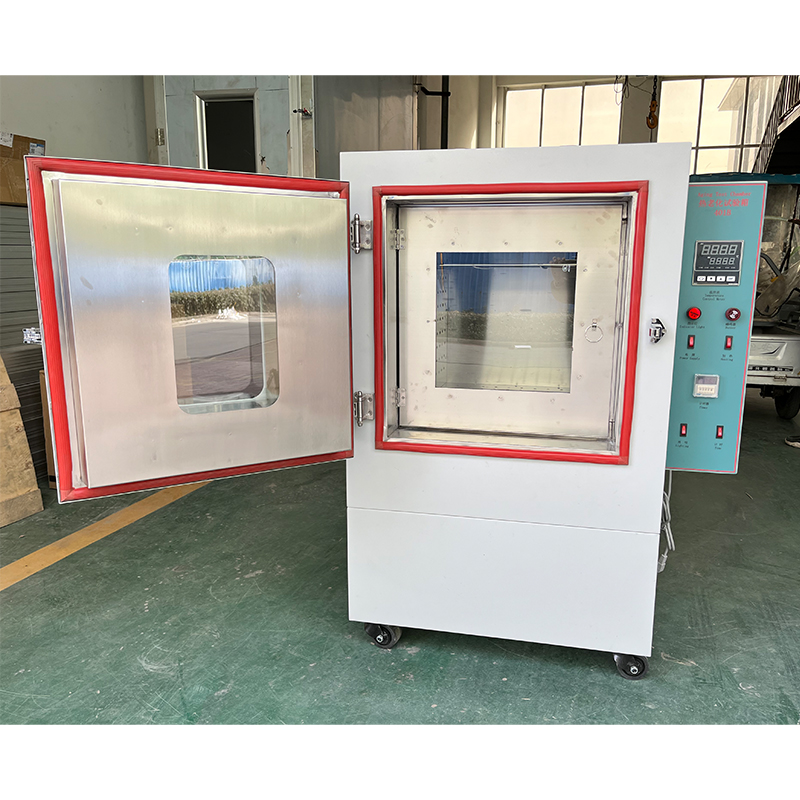

computer control tensile strength tester manufacturer

3. Data Management The integration of computer systems allows for effective data management. Modern tensile strength testers are often equipped with software that not only records results in real-time but also analyzes data and generates comprehensive reports. Manufacturers can easily track material performance over time, identify trends, and make informed decisions based on solid evidence.

4. Customization and Versatility Computer-controlled tensile strength testers can be programmed to conduct various tests according to specific material requirements and industry standards. This versatility enables manufacturers to tailor their testing processes to meet the unique demands of their products, ensuring compliance with regulatory standards and customer specifications.

5. Remote Monitoring and Control With advancements in technology, many systems now offer remote monitoring capabilities. Operators can oversee tests from a distance, adjusting parameters and responding to any issues in real-time. This ability enhances operational flexibility and ensures efficient use of resources.

Choosing the Right Manufacturer

When selecting a computer-controlled tensile strength tester, it is crucial for manufacturers to choose a reputable and experienced manufacturer. A quality manufacturer will not only provide cutting-edge testing equipment but also offer essential support, including training, maintenance, and updates. Look for companies that have a proven track record in the industry and are committed to innovation and customer satisfaction.

Conclusion

In conclusion, the adoption of computer-controlled tensile strength testers represents a significant advancement in the field of material testing. Their precision, efficiency, and ability to generate valuable data make them indispensable tools for manufacturers across a wide range of industries. As the demand for high-quality materials continues to rise, investing in advanced testing technology will be key to maintaining competitiveness and achieving product excellence.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy