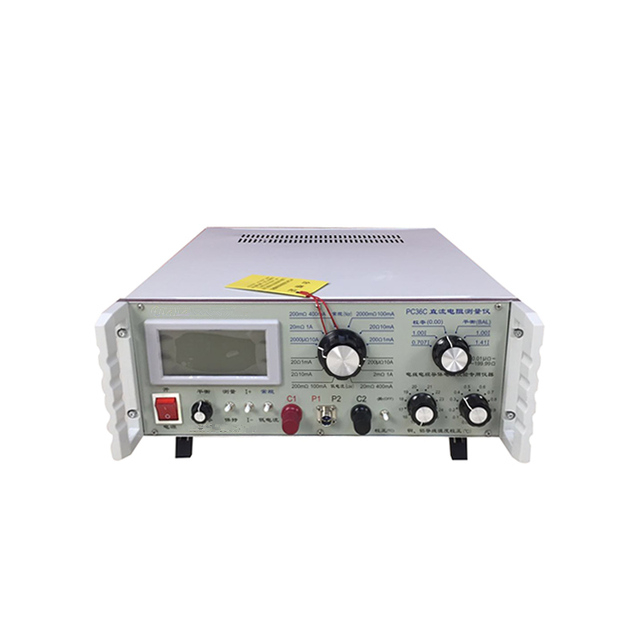

PC36C DC Resistance Meter: High Precision & Portable

Advancing Precision in Electrical Testing: The Role of Current Resistance Measurement

In the intricate world of electrical engineering and industrial maintenance, the accurate measurement of direct current resistance stands as a critical pillar for ensuring operational safety, system efficiency, and product longevity. From assessing the integrity of conductor materials in power cables to verifying the winding resistance of transformers and motors, precision in this domain is non-negotiable. Industry trends continue to emphasize higher reliability, reduced downtime, and enhanced predictive maintenance capabilities, driving the demand for advanced measuring instruments. The advent of sophisticated technologies has transformed resistance measurement from a rudimentary task into a highly specialized discipline, crucial for compliance with stringent international standards and for mitigating potential failures in critical infrastructure. The growing complexity of electrical systems across diverse sectors necessitates tools that not only offer unparalleled accuracy but also robust performance in challenging industrial environments. This critical requirement is precisely where the PC36C Direct Current Resistance Measuring Instrument establishes itself as an indispensable asset, providing the precision and reliability demanded by modern industrial applications. It represents a significant leap forward in diagnostic capabilities, empowering engineers and technicians to make informed decisions that safeguard assets and optimize operational parameters. Its design integrates cutting-edge measurement principles with user-centric functionalities, ensuring that even the most demanding tests are performed with ultimate confidence and efficiency.

Unveiling the Core: Technical Parameters of the PC36C Instrument

The performance of any precision instrument is fundamentally defined by its technical specifications, and the PC36C Direct Current Resistance Measuring Instrument is engineered to meet the highest benchmarks in the industry. Understanding these parameters is crucial for technical professionals assessing its suitability for specific applications. The instrument employs the advanced four-terminal Kelvin measurement method, which effectively eliminates errors caused by lead resistance, ensuring highly accurate readings, particularly for low resistance values. This method is an industry standard for precise resistance measurement. Its broad measurement range, typically from micro-ohms to several kilo-ohms, accommodates a diverse array of components, from large power transformer windings to delicate electronic circuit traces. Key technical specifications include measurement accuracy, often expressed as a percentage of the reading plus a fixed number of digits, which signifies its precision. Resolution, representing the smallest change in resistance the instrument can detect, is another vital factor, ensuring that even minute variations are captured. The maximum test current, a critical parameter, determines the instrument's capability to test inductive loads without saturation, directly influencing the stability and speed of measurements. Moreover, built-in temperature compensation mechanisms are paramount; as resistance is highly dependent on temperature, these features automatically adjust readings to a standard reference temperature (e.g., 20°C or 75°C), providing consistent and comparable data irrespective of environmental conditions. The instrument's internal data storage capacity, communication interfaces (such as USB, RS232), and software compatibility further enhance its utility for data logging, analysis, and integration into larger diagnostic systems, making it a comprehensive solution for modern electrical testing demands.

| Parameter | Specification (Typical for PC36C) | Description/Benefit |

|---|---|---|

| Measurement Range | 0.01 µΩ to 30 kΩ | Wide range suitable for various electrical components, from low-resistance cables to high-resistance windings. |

| Accuracy | ±(0.05% reading + 2 digits) | High precision ensures reliable diagnostic data for critical applications. |

| Resolution | 0.01 µΩ (lowest range) | Detects even minute changes in resistance, crucial for early fault detection. |

| Test Current | 1 mA to 10 A (selectable) | Supports various testing requirements, including inductive loads, ensuring stable readings. |

| Measurement Method | Four-terminal (Kelvin) | Eliminates lead resistance errors for highly accurate low-resistance measurements. |

| Temperature Compensation | Automatic to 20°C or 75°C | Ensures consistent and comparable readings regardless of ambient temperature. |

| Data Storage | Up to 1000 sets of readings | Facilitates trend analysis and historical data tracking for predictive maintenance. |

| Interface | USB, RS232 | Enables seamless data transfer to PC for analysis and reporting. |

| Display | Large LCD with backlight | Clear visibility of readings even in low-light conditions, enhancing usability. |

The Journey of Precision: Manufacturing and Quality Assurance of the PC36C

The robust performance and enduring reliability of the PC36C Direct Current Resistance Measuring Instrument stem from a meticulously controlled manufacturing process, adhering to the highest industry standards. The journey begins with the selection of premium materials; for instance, critical components like measurement leads and connectors often utilize high-purity copper and specialized alloys, ensuring minimal contact resistance and maximum signal integrity. The instrument's enclosure is typically constructed from high-grade, impact-resistant ABS or similar engineering plastics, sometimes with reinforced metal elements, providing exceptional durability and resistance to harsh industrial environments, including those found in petrochemical or metallurgical plants where corrosive agents or extreme temperatures are prevalent. Manufacturing processes involve precision CNC machining for creating intricate internal structures that house sensitive electronic components, ensuring perfect alignment and stability. Surface treatments, such as anodizing for metal parts or specialized coatings for circuit boards, enhance corrosion resistance and electrical insulation, contributing to a longer service life, often exceeding 10 years with proper maintenance. Quality control is paramount at every stage, from component validation to final assembly. Each PC36C Direct Current Resistance Measuring Instrument undergoes rigorous calibration and testing procedures compliant with international standards such as ISO/IEC 17025 for calibration laboratories and ANSI/NCSL Z540.3 for measurement and test equipment. These include environmental chamber tests to assess performance under varying temperatures and humidity, electromagnetic compatibility (EMC) testing to ensure resilience against electrical noise, and exhaustive functional tests to verify measurement accuracy across its entire range. This stringent manufacturing and testing regimen guarantees that the PC36C delivers consistent, reliable performance throughout its operational lifespan, making it an ideal choice for industries like power transmission, telecommunications, and automotive manufacturing, where precision and durability are critical for operational continuity and safety.

Beyond Measurement: Application Scenarios and Strategic Advantages

The versatility and precision of the PC36C Direct Current Resistance Measuring Instrument extend its utility across a broad spectrum of industrial applications, making it an indispensable tool for engineers and maintenance professionals. In the power sector, it is crucial for assessing the integrity of transformer windings, circuit breaker contacts, and busbar connections, where even slight increases in resistance can lead to significant energy losses and potential overheating, thus ensuring energy efficiency and preventing catastrophic failures. For cable manufacturers and utility companies, the PC36C is vital for verifying the resistance of power and communication cables, ensuring they meet specified standards and can reliably transmit current over long distances. Within the petrochemical industry, the instrument is utilized for inspecting grounding systems and cathodic protection systems, critical for preventing corrosion and ensuring safety in hazardous environments, showcasing its anti-corrosion application advantage. In metallurgy, it aids in quality control of conductive materials and components. Furthermore, the PC36C Direct Current Resistance Measuring Instrument finds significant application in the manufacturing of electric motors and generators, allowing for precise measurement of winding resistance to diagnose insulation degradation or short circuits, thereby extending equipment lifespan and optimizing performance. Beyond traditional industries, its capabilities are highly valued in research and development laboratories for material characterization and in advanced electronics manufacturing for quality assurance of components. Its portable design and user-friendly interface facilitate on-site testing, significantly reducing downtime and enabling proactive maintenance strategies. The instrument's ability to provide rapid, accurate, and repeatable measurements translates directly into operational efficiency, cost savings through reduced energy consumption (due to early detection of high-resistance faults), and enhanced safety across all these diverse sectors.

Beyond the Standard: Advanced Technical Features and Competitive Differentiation

While many instruments can measure resistance, the PC36C Direct Current Resistance Measuring Instrument distinguishes itself through a suite of advanced technical features designed for unparalleled performance and operational convenience in demanding B2B environments. One significant advantage is its sophisticated digital signal processing (DSP) capabilities, which filter out electrical noise and interference prevalent in industrial settings, ensuring stable and accurate readings even in challenging electromagnetic environments. This is particularly crucial when testing live systems or within substation environments. Unlike simpler ohmmeters, the PC36C incorporates intelligent current injection algorithms that optimize the test current for various load types, significantly reducing the stabilization time for inductive loads like transformers and motors. This acceleration of measurement cycles directly translates to increased operational efficiency and reduced test durations, especially valuable for extensive maintenance routines. Its large, backlit LCD display provides crystal-clear readings and intuitive navigation, enhancing user experience and reducing the potential for operational errors. Furthermore, the instrument often features a robust internal memory for storing thousands of readings, complete with time stamps and test configurations, facilitating comprehensive data logging and trend analysis. Connectivity options such as USB or RS232 ports allow seamless integration with PC-based analysis software, enabling professional reporting, historical data comparison, and integration into existing asset management systems. The combination of its wide measurement range, high accuracy, rapid stabilization, and data management capabilities positions the PC36C Direct Current Resistance Measuring Instrument as a superior choice compared to conventional alternatives, offering a compelling competitive edge by delivering precision, speed, and analytical depth required for modern industrial diagnostics.

Partners in Progress: Manufacturer Leadership and Custom Solutions

Choosing the right instrument is not solely about specifications; it is also about partnering with a manufacturer that demonstrates unparalleled industry authority, commitment to innovation, and dedicated customer support. As a leading provider in electrical testing equipment, our company brings decades of specialized experience to the forefront, with a deep understanding of the evolving needs of various industries. Our dedication to research and development ensures that instruments like the PC36C Direct Current Resistance Measuring Instrument consistently incorporate the latest technological advancements and adhere to the highest international quality standards, including ISO 9001 certification for our manufacturing processes. Our long-standing service record, spanning over 20 years in the industry, underscores our reliability and expertise, having served a vast portfolio of clients ranging from national power grids to major industrial conglomerates. We believe in building lasting relationships, offering not just a product but a comprehensive solution. This includes the flexibility to provide customized solutions tailored to specific client requirements, such as integrating the PC36C Direct Current Resistance Measuring Instrument into automated test systems, developing bespoke software interfaces, or providing specialized test leads for unique applications. Our collaboration with global industry leaders and prestigious research institutions further solidifies our authoritative position, ensuring our products are at the cutting edge of technological innovation and perfectly aligned with industry demands. This commitment to excellence, coupled with our robust pre-sales consultation and post-sales technical support, differentiates us from competitors. Our unwavering focus on customer success is reflected in our proactive approach to addressing technical challenges, offering training programs, and providing rapid calibration and repair services, ensuring optimal performance and maximum uptime for our clients' critical operations.

Real-World Impact: Application Cases and Customer Testimonials

The practical utility and transformative impact of the PC36C Direct Current Resistance Measuring Instrument are best illustrated through its successful deployment in various demanding real-world scenarios, backed by positive customer feedback. For instance, a leading national power utility successfully integrated multiple PC36C units into their routine substation maintenance program. Previously, diagnosing resistance issues in aging circuit breaker contacts was a time-consuming and often inaccurate process, leading to unscheduled outages. With the PC36C’s rapid and precise measurements, technicians could quickly identify degrading contacts, enabling predictive maintenance. This resulted in a reported 15% reduction in unscheduled power interruptions and significant cost savings associated with preventive repairs over reactive fixes. In another case, a prominent manufacturer of large industrial motors adopted the PC36C for their final quality control checks. Prior to this, inconsistencies in winding resistance measurements occasionally led to products being shipped with latent defects. The high accuracy and repeatability of the PC36C Direct Current Resistance Measuring Instrument ensured that every motor met stringent quality specifications, leading to a noticeable decrease in warranty claims and an improvement in overall product reputation. A customer testimonial from their Chief Quality Engineer highlights, "The PC36C has become an indispensable part of our quality assurance. Its reliability and ease of use have directly contributed to our enhanced product quality and customer satisfaction." Furthermore, a telecommunications company utilized the PC36C to troubleshoot resistance variations in their extensive copper cable networks. The instrument's portability allowed field engineers to quickly pinpoint fault locations, drastically reducing mean time to repair (MTTR) and improving network uptime, which is critical for maintaining service level agreements (SLAs). These diverse application cases underscore the instrument's proven capability to deliver tangible operational benefits and reinforce its standing as a trusted solution for critical resistance measurement needs across industries.

Ensuring Confidence: Trustworthiness Through Support and Assurance

Trust is foundational in B2B relationships, especially when dealing with critical industrial equipment. Our commitment to trustworthiness for the PC36C Direct Current Resistance Measuring Instrument is reflected in our transparent policies and comprehensive support infrastructure. We understand that purchasing a high-precision instrument involves more than just the product itself; it encompasses reliable delivery, robust post-sales support, and clear guarantees. The typical delivery cycle for the PC36C is between 2-4 weeks, depending on customization requirements and geographical location, with expedited options available upon request to meet urgent operational needs. Each instrument comes with a standard 24-month warranty, covering manufacturing defects and ensuring peace of mind, with extended warranty options also available for long-term investments. Our dedicated customer support team is available through multiple channels—phone, email, and live chat—to address technical queries, provide operational guidance, and assist with troubleshooting. We also offer comprehensive training programs, both on-site and remote, to ensure that your technical staff are fully proficient in utilizing the PC36C Direct Current Resistance Measuring Instrument to its maximum potential. Furthermore, a robust calibration and service network ensures that your instrument remains accurate and performs optimally throughout its lifespan. We maintain a full inventory of genuine spare parts and offer efficient repair services, minimizing any potential downtime. Our FAQ section below addresses common questions regarding operation, maintenance, and compatibility, providing immediate answers to typical concerns and reinforcing our commitment to proactive customer service. This holistic approach to support and assurance is designed to build lasting trust and confidence in our products and services, affirming our role as a reliable partner in your critical electrical testing endeavors.

Frequently Asked Questions (FAQs)

-

Q: What is the primary difference between a two-terminal and a four-terminal resistance measurement?

A: A two-terminal measurement includes the resistance of the test leads and contact resistance in the reading, which can significantly affect accuracy, especially for low resistance values. A four-terminal (Kelvin) measurement, as used by the PC36C, uses separate current and voltage leads, effectively eliminating the influence of lead and contact resistance, providing much higher accuracy for precise applications. -

Q: Can the PC36C be used for measurements on highly inductive loads like power transformers?

A: Yes, the PC36C Direct Current Resistance Measuring Instrument is specifically designed with advanced algorithms and high test current capabilities (up to 10A) to handle highly inductive loads. It ensures stable and accurate measurements by compensating for the inductive kickback, reducing measurement stabilization time significantly. -

Q: Is temperature compensation automatic with the PC36C?

A: Yes, the PC36C features automatic temperature compensation. Users can input the ambient temperature or use an optional external temperature sensor. The instrument then automatically corrects the resistance reading to a standard reference temperature (e.g., 20°C or 75°C), ensuring consistent and comparable data regardless of the test environment. -

Q: What kind of data logging and reporting capabilities does the PC36C offer?

A: The PC36C has significant internal memory for storing multiple sets of measurement data. It supports connectivity via USB and RS232, allowing for seamless data transfer to a PC. Accompanying software enables detailed analysis, trend plotting, and the generation of professional reports, crucial for predictive maintenance and compliance documentation.

Conclusion: The Future of Precision Resistance Measurement

In an era where the reliability of electrical systems directly impacts operational efficiency, safety, and profitability, the role of precise and dependable resistance measurement instruments cannot be overstated. The PC36C Direct Current Resistance Measuring Instrument stands as a testament to advanced engineering and a deep understanding of industrial demands. Its robust technical specifications, encompassing a wide measurement range, exceptional accuracy, and intelligent compensation mechanisms, make it an ideal choice for diverse applications, from critical infrastructure in the power sector to quality control in high-tech manufacturing. The meticulous manufacturing process, adherence to international standards, and comprehensive quality assurance protocols ensure its long-term durability and consistent performance in the most challenging environments. Beyond its technical prowess, the PC36C is backed by a manufacturer with a proven track record of industry leadership, a commitment to innovation, and a robust support infrastructure that prioritizes customer success. The ability to provide customized solutions, combined with extensive warranty coverage, efficient delivery, and responsive technical assistance, further solidifies its position as a trusted partner for businesses globally. Investing in the PC36C Direct Current Resistance Measuring Instrument is not merely acquiring a device; it is embracing a solution that delivers unparalleled precision, enhances predictive maintenance capabilities, reduces operational risks, and ultimately contributes to the sustainable and efficient operation of complex electrical systems.

References

- IEEE Std 118-1978 (R1992) - IEEE Guide for Selection and Installation of Dry Type Transformers.

- IEC 60076-1: Power transformers – Part 1: General.

- ASTM B193-16: Standard Test Method for Resistivity of Electrical Conductor Materials.

- National Institute of Standards and Technology (NIST) - Guidelines for Measurement and Uncertainty.

- Kelvin, W. T. (1862). On the Electro-dynamic Qualities of Metals. Philosophical Transactions of the Royal Society of London.

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

-

Electrical Properties Testing in Modern Applications

NewsAug.23,2025

-

Universal Tensile Testing Machine Applications in Modern Electrical and Material Testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy