smoke density test chamber company

Understanding Smoke Density Test Chambers A Comprehensive Overview

In the world of fire safety and materials testing, smoke density test chambers play a crucial role in assessing the behavior of materials when exposed to fire. The ability to accurately measure the density of smoke produced by burning materials helps manufacturers, researchers, and safety regulators to determine the fire safety properties of various substances. This article will delve into the importance of smoke density testing, the design and functionality of smoke density test chambers, and the implications of the results obtained from these tests.

Importance of Smoke Density Testing

The significance of smoke density testing cannot be overstated. Smoke produced during a fire can be just as dangerous as the flames themselves. High levels of smoke can lead to reduced visibility, which complicates evacuation efforts and increases the risk of injury or lethality. Therefore, understanding how much smoke a material produces can inform regulations, improve safety standards, and guide manufacturers in developing safer products.

Smoke density tests are particularly important for materials used in building construction, automotive interiors, textiles, and electronics. For example, the aviation and automotive industries utilize smoke density test results to ensure that materials used in their products do not not only resist flames but also minimize smoke production, thereby protecting passengers and crew in the event of a fire.

Overview of Smoke Density Test Chambers

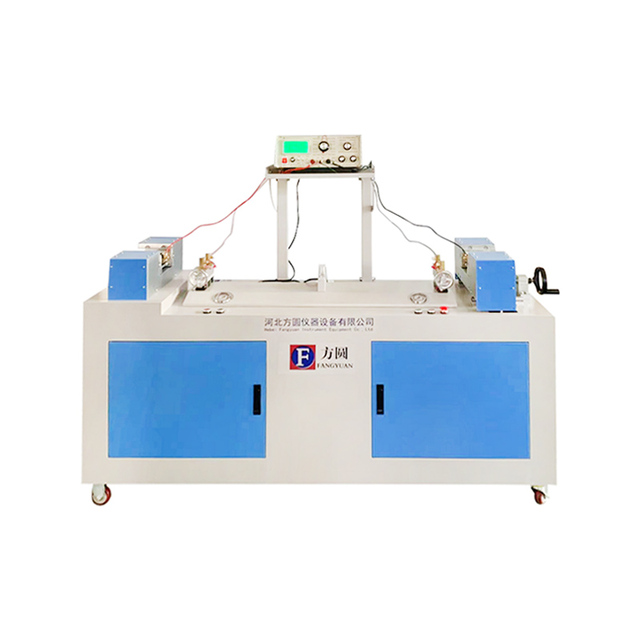

A smoke density test chamber is a specialized device designed to evaluate the density of smoke emitted by a sample under controlled conditions. These chambers are equipped with various features that enable accurate and reproducible measurements.

Typically, a smoke density test chamber consists of

1. Sample Holder This is where the material is placed for testing. The holder is designed to accommodate different shapes and sizes of samples while ensuring uniform exposure to the ignition source.

smoke density test chamber company

2. Ignition Source The ignition source is crucial for simulating real fire conditions. It must produce a standardized flame that is capable of igniting the sample without introducing variables that could skew the results.

3. Smoke Measurement System This includes a photometric system that measures light attenuation caused by smoke particles in the air. As smoke from the burning sample fills the chamber, the system detects the density of smoke, allowing for real-time monitoring and analysis.

4. Ventilation System To prevent the accumulation of toxic fumes and ensure safety during testing, a proper ventilation system is included in the design of the chamber. This system can effectively remove smoke after testing to facilitate visual inspection and ensure safety.

5. Control and Data Acquisition System Modern smoke density test chambers often come equipped with advanced software and sensors that allow for automated testing protocols. This capability enhances precision in capturing data and facilitates analysis of the results.

Applications and Implications of Results

The results obtained from smoke density tests have several applications across various industries. They help manufacturers meet regulatory requirements, improve product design, and enhance safety measures. Additionally, the data obtained can be used to develop fire safety guidelines, training programs for fire personnel, and emergency response protocols.

Furthermore, understanding smoke density not only aids in compliance but also inspires innovation. With insights gained from testing, researchers and engineers can work on creating new materials that are more fire-resistant and produce less smoke, thereby contributing to safer environments.

Conclusion

Smoke density test chambers are integral to the evaluation of material safety in the event of a fire. By providing a controlled environment for testing, these chambers enable accurate measurement of smoke production, which is vital for safeguarding lives and property. As industries continue to prioritize safety and compliance, the role of smoke density testing will only become more essential in the pursuit of safer, more reliable materials. With ongoing advancements in testing technology, we can expect even greater accuracy and efficiency in the assessment of smoke density and its implications for fire safety.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy