Cable Bending Test Machine High-Cycle Testing & Reliable Suppliers

- Overview of Cable Bending Test Machines

- Technical Advantages Driving Industry Demand

- Comparative Analysis of Leading Suppliers

- Customized Solutions for Diverse Testing Needs

- Performance Metrics and Data-Driven Insights

- Real-World Applications Across Industries

- Future Trends in Cable Bending Testing Technology

(cable bending test machine)

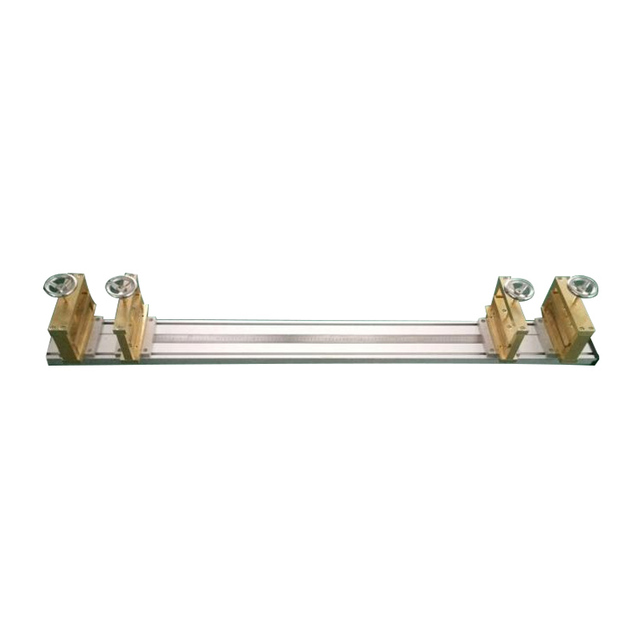

Understanding the Essentials of Cable Bending Test Machines

Cable bending test machines are critical for evaluating the durability and flexibility of cables under repetitive stress. These systems simulate real-world conditions to measure how cables withstand bending cycles, torsion, and mechanical wear. Industries such as automotive, aerospace, and telecommunications rely on these tests to ensure compliance with international standards like IEC 61158 and ISO 6722. A typical machine operates at speeds of 10–60 cycles per minute, applying angular displacements up to ±180°, with load capacities ranging from 50N to 500N.

Technical Advantages Driving Industry Demand

Modern cable repeated bending test machines integrate servo-motor controls, programmable logic controllers (PLCs), and real-time data tracking. Key features include:

- Precision sensors with ±0.5% measurement accuracy

- Modular designs for testing cables from 2mm to 50mm in diameter

- Automated failure detection via current leakage or resistance monitoring

Such advancements reduce testing time by 30% compared to manual methods while improving repeatability.

Comparative Analysis of Leading Suppliers

| Supplier | Location | Annual Output | Key Certification |

|---|---|---|---|

| TechTron Systems | Germany | 1,200 units | CE, ISO 9001 |

| EliteTest Solutions | USA | 950 units | UL, AS9100 |

| Precision Dynamics Co. | China | 2,500 units | ISO 17025 |

Customized Solutions for Diverse Testing Needs

Manufacturers offer tailored configurations to address specific requirements:

- Adjustable bending radii (10mm–300mm)

- Multi-axis motion for complex cable routing simulations

- Climate-controlled chambers (-40°C to +150°C)

For instance, a European automotive supplier recently deployed a system testing 10,000 cycles at 90° angles with integrated thermal cycling.

Performance Metrics and Data-Driven Insights

Advanced models generate comprehensive reports tracking:

- Cycle count vs. insulation resistance degradation

- Torque variations during bidirectional bending

- Micro-ohmmeter readings for conductor integrity

Data shows industrial-grade machines maintain ±1.5% torque consistency across 50,000 cycles.

Real-World Applications Across Industries

Case studies demonstrate operational impact:

- EV manufacturers validating high-voltage charging cables

- Aerospace firms testing flight control wire harnesses

- Telecom providers ensuring fiber optic cable reliability

One robotics company achieved 98% predictive maintenance accuracy by correlating bend test data with field failure rates.

Innovating Cable Bending Test Machine Capabilities

The next generation of cable repeated bending test machines will incorporate AI-powered predictive analytics and IoT connectivity. Emerging technologies enable real-time remote monitoring and adaptive test protocols, reducing validation cycles by up to 40%. As global cable production grows at 6.2% CAGR (2023–2030), advanced testing solutions remain pivotal for quality assurance.

(cable bending test machine)

FAQS on cable bending test machine

Q: What should I consider when choosing cable repeated bending test machine suppliers?

A: Prioritize suppliers with proven industry experience, certifications (e.g., ISO), and positive client testimonials. Ensure they offer after-sales support and customizable testing solutions.

Q: How do cable repeated bending test machine factories ensure product quality?

A: Reputable factories use precision engineering, standardized testing protocols, and rigorous quality checks. Many comply with international standards like IEC or ASTM for consistent performance.

Q: Are there companies offering cable bending test machines with custom testing cycles?

A: Yes, specialized companies provide adjustable cycle counts, bend angles, and load capacities. Confirm their ability to tailor machines to specific industry standards like UL or EN.

Q: What features distinguish high-quality cable repeated bending test machines?

A: Look for durable construction, accurate motion control, and real-time data logging. Advanced models include automated reporting and compliance with MIL-STD or ISO 20485 specifications.

Q: Can cable bending test machine suppliers provide global shipping and installation support?

A: Many established suppliers offer worldwide shipping and onsite installation services. Verify warranty terms, local service networks, and multilingual technical assistance availability.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy