TXWL-600 elektro-gidravlik servo gorizontal tortishish sinov mashinasi

Mahsulot tavsifi

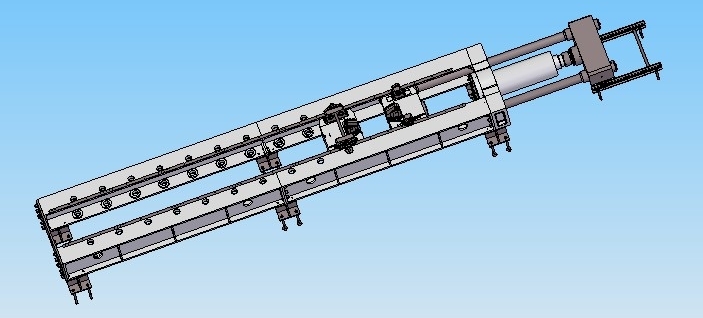

TXWL-600 elektro-gidravlik servo gorizontal valentlik sinov mashinasi gorizontal ramka tuzilishini qabul qiladi, bitta novda ikki tomonlama pistonli silindr sinov kuchini ta'minlaydi va kompyuterni boshqarish tizimi servo valf va boshqa komponentlarni nazorat qilish orqali sinov jarayonini avtomatik boshqarishni amalga oshiradi, sinov ma'lumotlar yuk sensori tomonidan aniq to'planadi va kompyuterga uzatiladi, tizim sinov natijalarini avtomatik ravishda tahlil qiladi, qayta ishlaydi va saqlaydi va printer to'g'ridan-to'g'ri kerakli test hisobotini chop etishi mumkin. Ushbu mashina asosan po'lat simli arqonning kuchlanish sinovi uchun ishlatiladi, ideal sinov uskunalari talablariga javob beradigan ilmiy tadqiqot va o'quv va boshqa sohalarning zamonaviy ishlab chiqarishidir.

Mashina tavsifi

1. Xost tizimi

Mashinaning asosiy qismi, asosan, asosiy mashina ramkasidan, yog 'tsilindrining o'rindig'idan, yog 'tsilindridan, harakatlanuvchi nurdan, old va orqa o'rindiq o'rindig'idan va yuk sensoridan iborat. U namunadagi maksimal 600kN yuk bilan valentlik sinovini o'tkazishi mumkin.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Sinov maydoni sinov xodimlarining xavfsizligini samarali himoya qila oladigan himoya qoplamasi bilan jihozlangan.

2. Neft manbalari tizimi

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Elektr bo'limi

Elektr boshqaruvi sinovdan o'tish zonasida joylashtirilgan va barcha turdagi operatsiyalarni bir qarashda aniq qilish uchun maxsus ishlab chiqilgan operatsion panel mavjud. Elektr komponentlari barqaror ishlash va ishonchli sifatga ega bo'lgan xalqaro mashhur brenddir.

Dasturiy ta'minot tizimi:

(1) Dasturlashtiriladigan funktsiyalarga ega Windows XP operatsion platformasiga asoslangan holda, teng tezlikda sinov kuchini boshqarish, teng tezlikda siljish nazorati, sinov kuchini ushlab turish, o'zgartirishni ushlab turish va boshqa sinov rejimlari turli xil sinov usullari talablariga javob berish uchun o'z xohishiga ko'ra birlashtirilishi mumkin. maksimal darajada va test uchun zarur bo'lgan turli xil ma'lumotlarni ko'rsatish, egri chizish, ma'lumotlarni qayta ishlash, saqlash va bosib chiqarish funktsiyalarini amalga oshirish.

(2) Servo valfning ochilishi va yo'nalishini nazorat qilish uchun kompyuter orqali servo valfga nazorat signalini yuboring, shu bilan silindrga oqimni nazorat qiladi va teng tezlikdagi sinov kuchini, teng tezlikda siljishni va hokazolarni nazorat qilishni amalga oshiradi. .

(3) Sinov kuchi va joy o'zgartirishning ikkita yopiq pastadir boshqaruvi bilan jihozlangan.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) Asosiy interfeys testning kundalik ishlashining barcha funktsiyalariga ega, masalan, namunaviy ma'lumotlarni kiritish, namuna tanlash, egri chizish, ma'lumotlarni ko'rsatish, ma'lumotlarni qayta ishlash, ma'lumotlarni tahlil qilish, sinov operatsiyasi va boshqalar. Sinov jarayoni oddiy va tez.

(6) Sinov hisobotini chop etish uchun ma'lumotlar printerga chiqarilishi mumkin.

(7) Tizimning ierarxik boshqaruvi, tizim parametrlari barcha ekspert foydalanuvchilar uchun ochiq bo'lib, tizimning moslashuvchanligi va ishonchliligini ta'minlaydi.

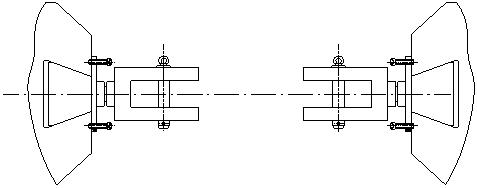

4. Aksessuarlar sinovi

Tel arqon sinov aksessuarlari bilan jihozlangan (pastga qarang) va boshqa aksessuarlar foydalanuvchi tomonidan taqdim etilgan standartga yoki namunaning kuchlanish talablariga muvofiq ishlab chiqariladi.

5.Xavfsizlikni himoya qilish qurilmalari

(1) Sinov kuchi maksimal sinov kuchidan yoki belgilangan qiymatdan 2% dan 5% gacha oshganida ortiqcha yuk himoyasi.

(2) Piston chegara holatiga o'tganda zarba himoyasi.

(3) Yog 'harorati, suyuqlik darajasi va yog'ga qarshilikni himoya qilish va ko'rsatkich qurilmalari bilan.

(4) Sinov maydonida namunaning sinishi va tushishining oldini olish uchun himoya qopqog'i mavjud.

(5) Favqulodda vaziyat yuzaga kelganda, to'g'ridan-to'g'ri boshqaruv kabinetidagi favqulodda to'xtatish tugmasini bosing

Texnik parametr

1.Maksimal sinov kuchi: 600kN

2.Test kuchini o'lchash diapazoni: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.Tensial sinov maydoni (piston zarbasidan tashqari): 20mm ~ 12000mm

5.Piston zarbasi: 1000mm

6.Pistonning maksimal ish tezligi: 100 mm/min

7.Deformatsiya ekstansometrining aniqligi: 0,01 mm

8. Asosiy mashinaning o'lchami (mm): 16000 (L) x 1300 (W) x 1000 (H) (himoya qopqog'idan tashqari)