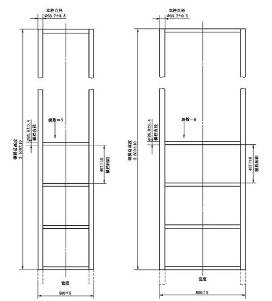

50 ton tensile tester

The Importance of a 50% 20 Ton Tensile Tester in Material Testing

In the field of material science and engineering, ensuring the reliability and durability of materials is of utmost importance. One of the essential tools for achieving this is the tensile tester. Among the various types of tensile testers, the 50% 20 ton tensile tester stands out due to its unique specifications and capabilities. In this article, we will dive into what a 50% 20 ton tensile tester is, its significance, and its applications in various industries.

Understanding Tensile Testing

Tensile testing is a mechanical test that determines how a material will react when it is subjected to tension. By applying a force to a material until it breaks, researchers can gather vital information about the material's properties, including tensile strength, elongation, and yield strength. These properties are crucial for engineers and designers to understand the limits of materials in different applications.

What is a 50% 20 Ton Tensile Tester?

A 50% 20 ton tensile tester refers to a tensile testing machine capable of applying a maximum load of 20 tons. The term 50% indicates that the tester can operate efficiently at half of its maximum capacity, which, in this case, would be 10 tons. This feature allows for versatile testing of a wide range of materials without the risk of damaging the equipment or the specimens being tested.

This type of tensile tester is equipped with advanced sensors and software that enable precise control and monitoring during the test. As the material is stretched, the tester measures the amount of force applied and the corresponding elongation of the material, generating a stress-strain curve that is essential for analyzing material behavior.

Significance of the 50% 20 Ton Tensile Tester

The significance of the 50% 20 ton tensile tester cannot be overstated. First and foremost, it offers an accurate and reliable means of testing materials that are widely used in various industries, such as construction, automotive, aerospace, and manufacturing. By using a tester with a capacity of 20 tons, engineers can effectively evaluate the performance of heavy-duty materials, ensuring that they meet the necessary standards and specifications.

50 ton tensile tester

Moreover, the ability to operate at 50% capacity ensures that even smaller or more delicate materials can be tested without the risk of excessive force, allowing for a more comprehensive understanding of material properties across different applications.

Applications in Different Industries

1. Construction In the construction industry, materials such as steel, concrete, and composites are subjected to various forces. A 50% 20 ton tensile tester helps verify the tensile strength of these materials, ensuring that they can withstand the loads they are designed to support.

2. Automotive The automotive industry relies heavily on tensile testing to ensure the safety and performance of components. From metals used in body frames to plastics in interior designs, testing these materials under tension helps prevent failures in real-world applications.

3. Aerospace Aircraft components are subject to extreme conditions, making rigorous testing paramount. A 50% 20 ton tensile tester is invaluable in assessing the structural integrity of materials used in aircraft, helping to maintain safety standards in aviation.

4. Manufacturing In manufacturing, tensile testing is crucial during the development of new materials and products. The insights gained from testing can lead to innovations and improvements in product design, enhancing overall quality.

Conclusion

The 50% 20 ton tensile tester plays a critical role in the field of material testing. Its ability to deliver precise and reliable results makes it an invaluable tool across various industries. As technology continues to evolve, the importance of such testing equipment will remain paramount in ensuring the safety, reliability, and performance of the materials we use in our daily lives. By investing in quality tensile testing equipment, industries can guarantee that their products stand the test of time and meet the demands of a rapidly changing world.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy