Innovative Test Setup for Measuring Custom Conductor Resistance Effectively and Accurately

Custom Conductor Resistance Test Fixture Ensuring Precision and Accuracy

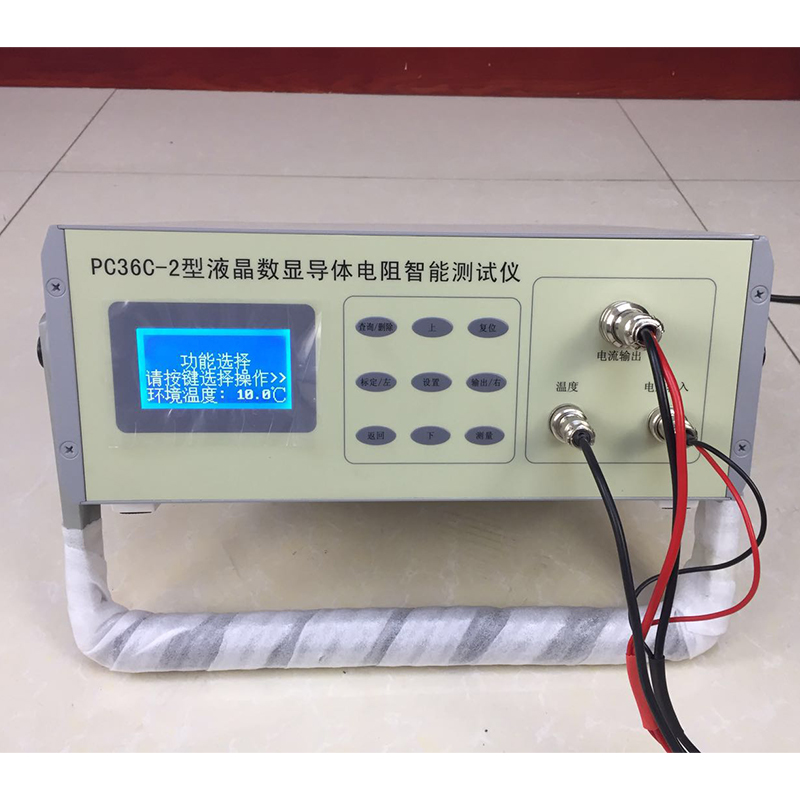

In the field of electrical engineering, conducting resistance tests on various types of conductors is crucial to ensuring the reliability and safety of electrical systems. A custom conductor resistance test fixture plays a vital role in this process, providing a specialized setup to measure the resistance of conductors with precision and accuracy. This article explores the importance, design considerations, and applications of custom conductor resistance test fixtures.

Importance of Resistance Testing

Resistance testing is fundamental for evaluating the performance characteristics of electrical conductors. The resistance of a conductor can influence the efficiency of electrical devices and systems. High resistance can lead to energy losses in the form of heat, which may compromise the performance and lifespan of electrical components. Additionally, low resistance is essential for minimizing voltage drops, ensuring that electrical signals are transmitted effectively.

In industrial and commercial applications, the integrity of electrical connections can directly impact safety. Poorly performing conductors can lead to equipment malfunctions, system failures, or even hazardous electrical conditions. Therefore, precision in measuring conductor resistance is non-negotiable, and custom testing fixtures provide the perfect solution for achieving this goal.

Features of Custom Test Fixtures

A custom conductor resistance test fixture is tailored to meet specific testing requirements, often combining various features that enhance functionality and accuracy

1. Material Selection The choice of materials for the fixture is vital. Conductive materials with low resistance, such as copper or aluminum, are often utilized to minimize any additional resistance introduced during testing.

2. Design Flexibility Custom test fixtures can be designed to accommodate different conductor sizes, shapes, and configurations. Whether testing cables, wire harnesses, or bus bars, a well-designed fixture ensures that the test subjects are held securely and consistently.

3. Connection Methods Advanced connection methods minimize contact resistance, enhancing measurement accuracy. Techniques such as soldering, crimping, or the use of high-quality connectors can achieve stable electrical connections.

custom conductor resistance test fixture

4. Integration with Measuring Equipment Many custom fixtures are designed to integrate seamlessly with resistance measurement devices, such as micro-ohm meters or digital multimeters. This integration allows for quick and easy data acquisition, simplifying the testing process.

5. Environmental Considerations Depending on the testing environment, fixtures can be designed to endure various conditions such as temperature extremes, humidity, or exposure to chemicals, ensuring longevity and reliability.

Applications of Custom Test Fixtures

Custom conductor resistance test fixtures find their utility in various sectors, including

1. Manufacturing In the production of electrical components, ensuring that conductors meet resistance specifications is essential for quality control. Custom fixtures can streamline the testing process during assembly lines, allowing manufacturers to maintain high standards.

2. Research and Development Engineers and scientists often require precise measurements for prototyping new conductor designs or materials. Custom fixtures help facilitate such research, providing reliable data essential for innovation.

3. Field Testing Custom fixtures can also be used for field testing in power generation and transmission systems. By providing a portable solution for resistance testing, engineers can assess the condition of conductors in situ, ensuring the reliability of the system.

4. Maintenance and Inspections Regular inspections of electrical systems help prevent failures and extend the lifespan of equipment. Custom fixtures enable maintenance personnel to quickly assess conductor resistance, identifying potential problems before they escalate.

Conclusion

In conclusion, a custom conductor resistance test fixture is an essential tool in ensuring the performance, reliability, and safety of electrical systems. By providing tailored solutions to measure conductor resistance accurately, these fixtures support various applications across industries. As technology continues to advance, the design and functionality of these fixtures will evolve, further enhancing their capabilities and applications in the ever-critical field of electrical engineering. Whether in manufacturing, research, field testing, or maintenance, the significance of accurate resistance measurement cannot be overstated. Investing in a custom test fixture not only contributes to operational efficiency but also promotes safety and reliability in electrical applications.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy